Macromolecular composite flocculant and preparation method and application thereof

A composite flocculant and polymer technology, which is applied in the field of water treatment, can solve problems such as difficulty in meeting national drinking water standards, poor deoiling effect of oily sewage, and inconspicuous decolorization, so as to achieve safe and reliable drinking water quality and deoiling effect Good, clear water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

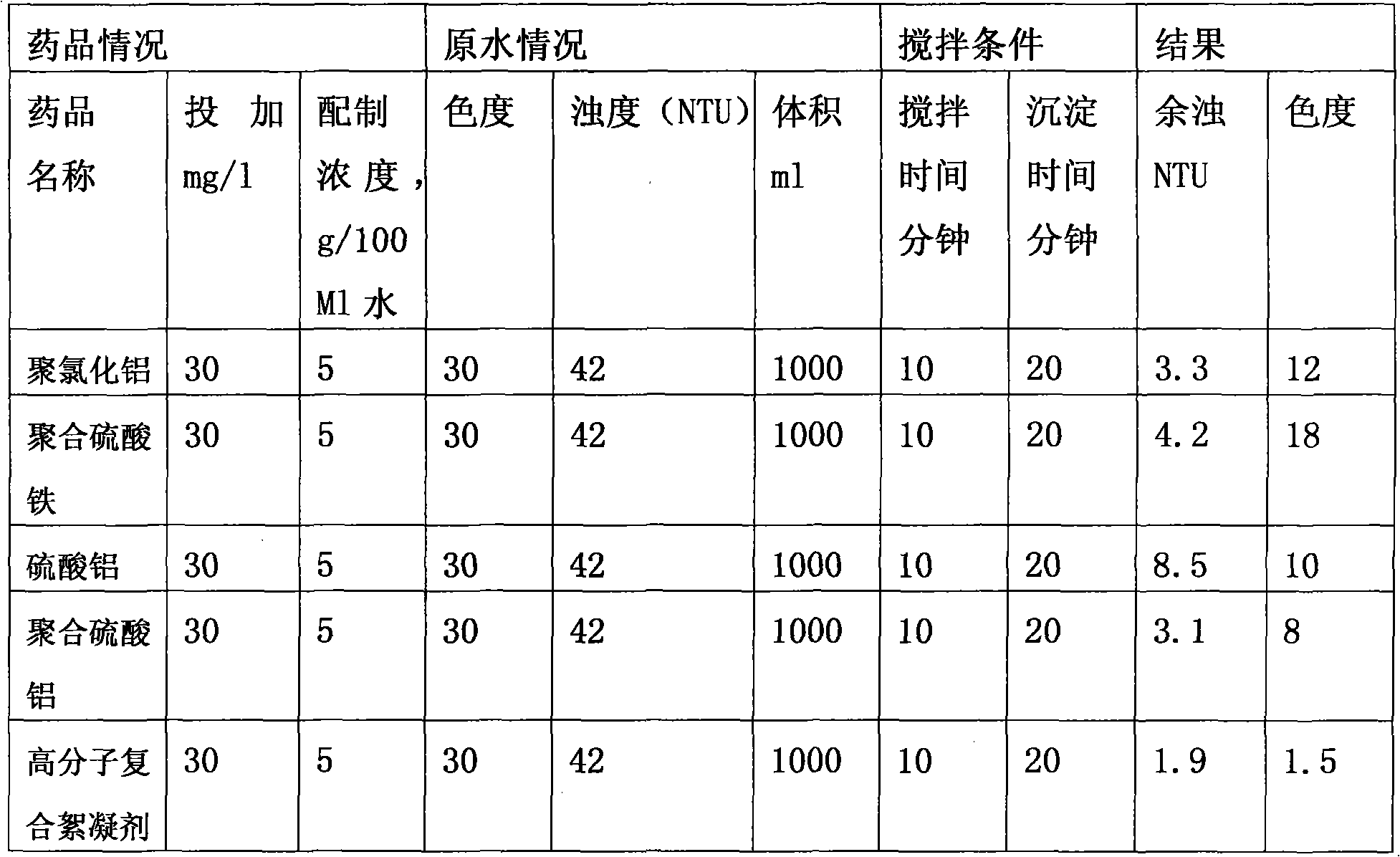

Examples

Embodiment 1

[0040] Embodiment 1 Preparation of a polymer composite flocculant

[0041] a. Preparation of polyaluminum sulfate aqueous solution: put accurately measured polyaluminum sulfate into a reaction kettle with metered water in advance, stir and dissolve at a temperature of 4°C-42°C, and adjust to contain 10% polyaluminum sulfate (as Al 2 o 3 meter) aqueous solution;

[0042] b. Preparation of polydimethyldiallyl ammonium chloride solution: put the accurately measured polydimethyldiallyl ammonium chloride colloid into the reaction kettle that has been put into the metered water in advance, at a temperature of 4°C-42°C , stir to dissolve, and adjust the intrinsic viscosity between 2.4dl / g;

[0043] c. Preparation of polymer composite flocculant: the polyaluminum sulfate aqueous solution prepared in step a and the polydimethyldiallyl ammonium chloride solution prepared in step b, according to the following ratio:

[0044] Polyaluminum sulfate aqueous solution 90%

[0045] Polydime...

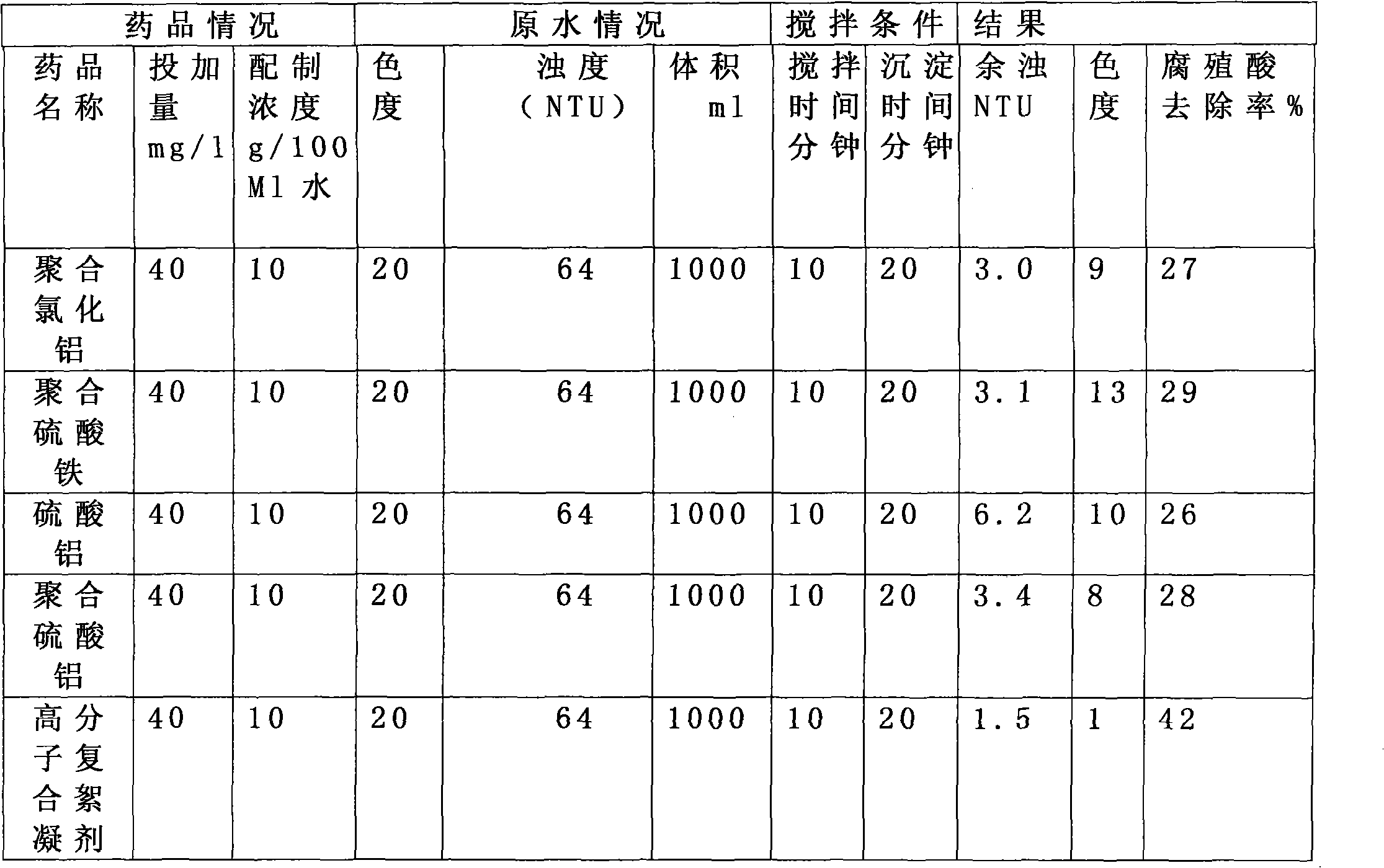

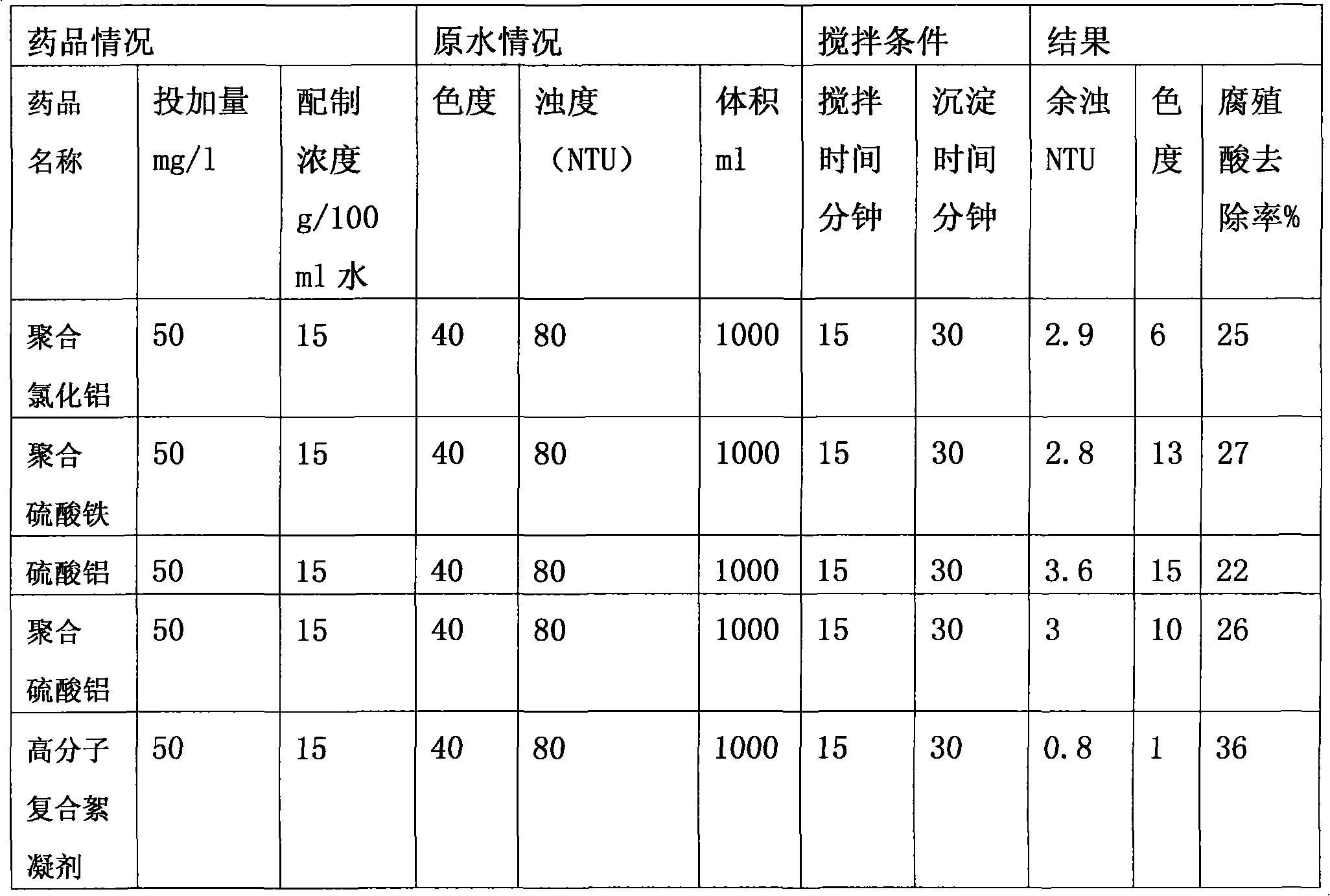

Embodiment 2

[0055] Embodiment 2 Preparation of another polymer composite flocculant

[0056] a. Preparation of polyaluminum sulfate aqueous solution: put accurately measured polyaluminum sulfate into a reaction kettle with metered water in advance, stir and dissolve at a temperature of 0°C-30°C, and adjust to contain 9% polyaluminum sulfate (as Al 2 o 3 meter) aqueous solution;

[0057] b. Preparation of polydimethyldiallyl ammonium chloride solution: put the accurately measured polydimethyldiallyl ammonium chloride colloid into the reaction kettle that has been put into metered water in advance, at a temperature of 0°C-30°C , stir and dissolve for 1 hour, and adjust the intrinsic viscosity between 2.6dl / g;

[0058] c. Preparation of polymer composite flocculant: the polyaluminum sulfate aqueous solution prepared in step a and the polydimethyldiallyl ammonium chloride solution prepared in step b, according to the following ratio:

[0059] Polyaluminum Sulfate Aqueous Solution 94%

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com