Process and device for treating tail gas and/or residual liquid in polycrystalline silicon production

A treatment process, polysilicon technology, applied in the fields of neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor equipment leaching effect, blockage of equipment and pipe nozzles , large workload of clearing blockage, etc., to achieve the effect of economical and reasonable maintenance cost, reduced workload, and small number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

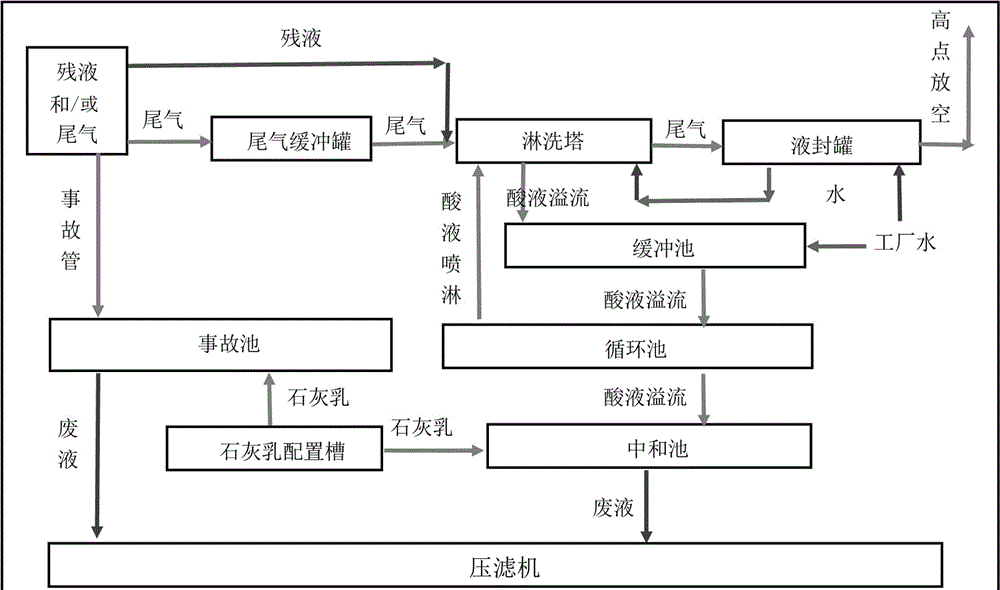

[0028] Below in conjunction with embodiment and attached figure 1 and 2 To further illustrate the present invention, but the scope of protection claimed in the present invention is not limited to the scope expressed in the examples.

[0029] Tail gas and / or residual liquid treatment process in polysilicon production, specifically including the following steps:

[0030] 1) Send the tail gas and / or residual liquid into the leaching tower, use weak acid water with a mass concentration of 2-5% to spray and clean in a countercurrent state, and the cleaned gas enters the liquid-sealed tank and is purified with clean water, and finally comes out The gas is vented; the cleaned liquid is sprayed as a weak acid water cycle;

[0031] 2) After the weak acid water sprayed by circulation in step 1) exceeds the limit concentration, discharge part of the waste acid water and add water to dilute to the required concentration for continued use. Add lime emulsion to the discharged waste acid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com