Preparation method for novel three-dimensional ordered macroporous chelating resin

A three-dimensional ordered, chelating resin technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of improving utilization rate, excellent mechanical properties, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

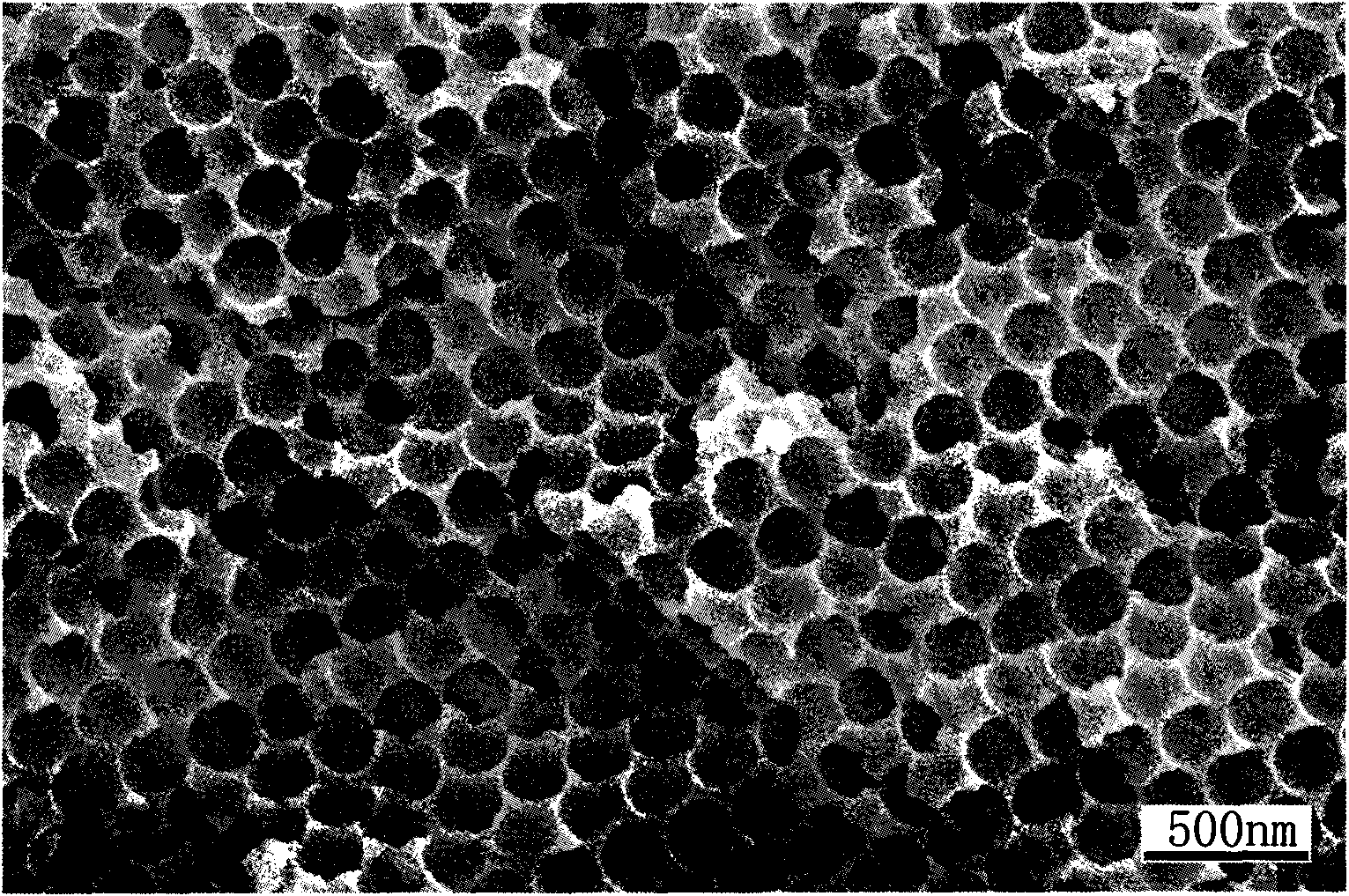

[0043] Preparation of 3DOM CLPS with average pore size of 80nm connected with 2-mercaptobenzothiazole.

[0044] (1) Preparation of silica colloidal crystal template

[0045] At room temperature, add 10g of absolute ethanol, 5.6g of 25% ammonia water, and 8.9g of distilled water in sequence in a three-necked flask equipped with electric stirring. After stirring evenly, quickly add 15.9g of tetraethyl orthosilicate and react for 8 hours Finally, pour the obtained suspension into a 500mL beaker, the solvent evaporates naturally at room temperature, and then sinter the template in a horse-boiling furnace at 200°C for 2 hours, and slowly lower it to room temperature to obtain silica gel with an average particle size of 80nm. crystal template.

[0046] (2) Preparation of three-dimensional ordered macroporous materials (3DOM)

[0047] After 0.0610mol styrene (6.35g), 0.0285mol (3.71g) divinylbenzene and 0.0503g initiator AIBN are fully dissolved in a 50mL beaker, the mixed solution...

Embodiment 2

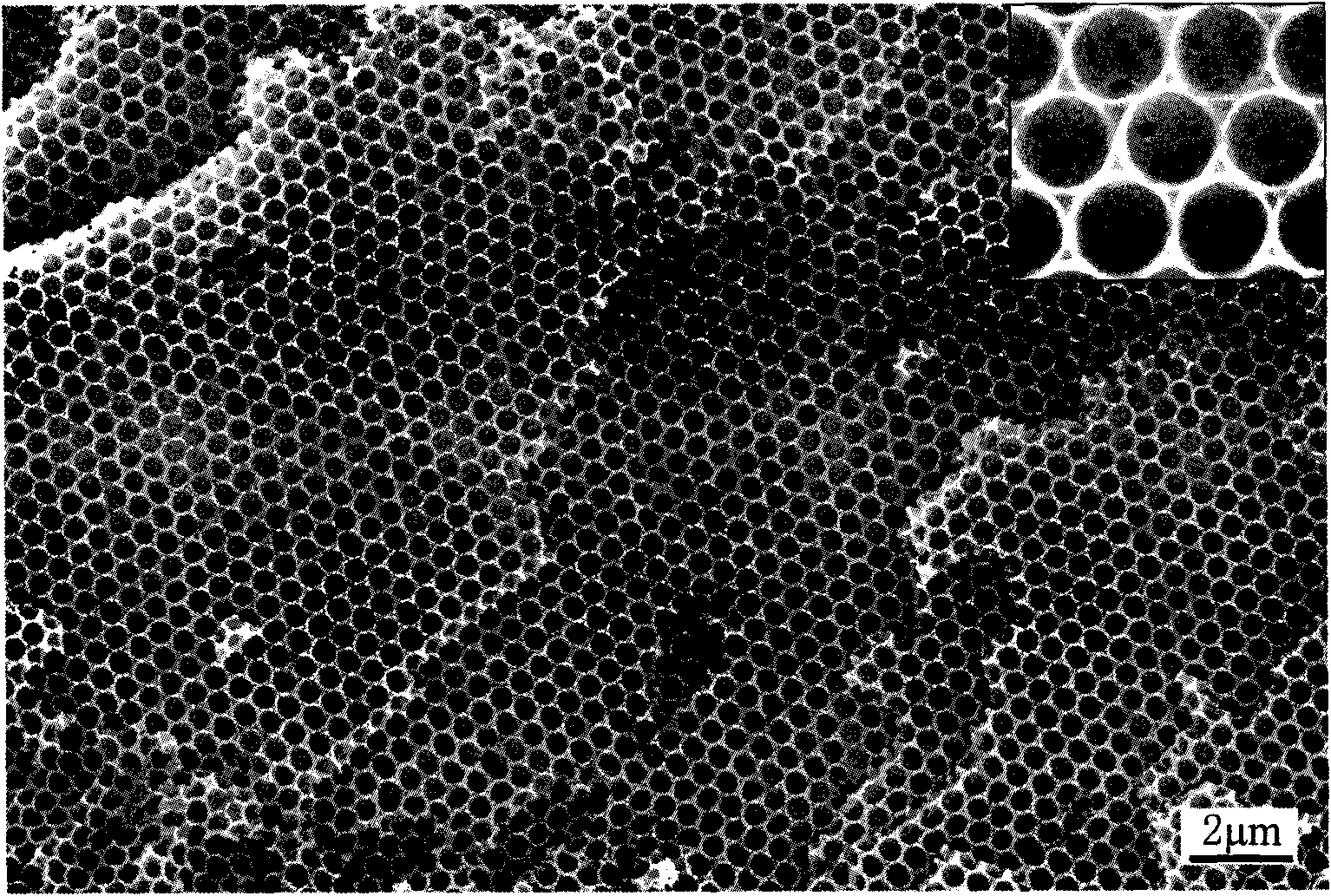

[0062] Preparation of 3DOM CLPS with an average pore size of 200nm coupled with 3-aminomethylpyridine.

[0063] (1) Preparation of silica template

[0064] The preparation steps of the silica template refer to Example 1, only the addition of reagents is adjusted: 12 g of absolute ethanol, 6.2 g of ammonia water with a percentage concentration of 25%, 10 g of distilled water, and 14.2 g of tetraethyl orthosilicate. A silica template with an average particle diameter of 200 nm was obtained.

[0065] (2) Preparation of three-dimensional ordered macroporous materials (3DOM)

[0066] After 0.0697mol styrene (7.25g), 0.0214mol divinylbenzene (2.79g) and 0.0502g dibenzoyl peroxide are fully dissolved in a 50mL beaker, the mixture is injected into a two-neck flask filled with a sintered template , soak the template until transparent. Polymerize at 65°C for 2 hours and at 80°C for 24 hours to obtain a three-dimensional ordered polymer / silica composite. The bulk polymer on the surfa...

Embodiment 3

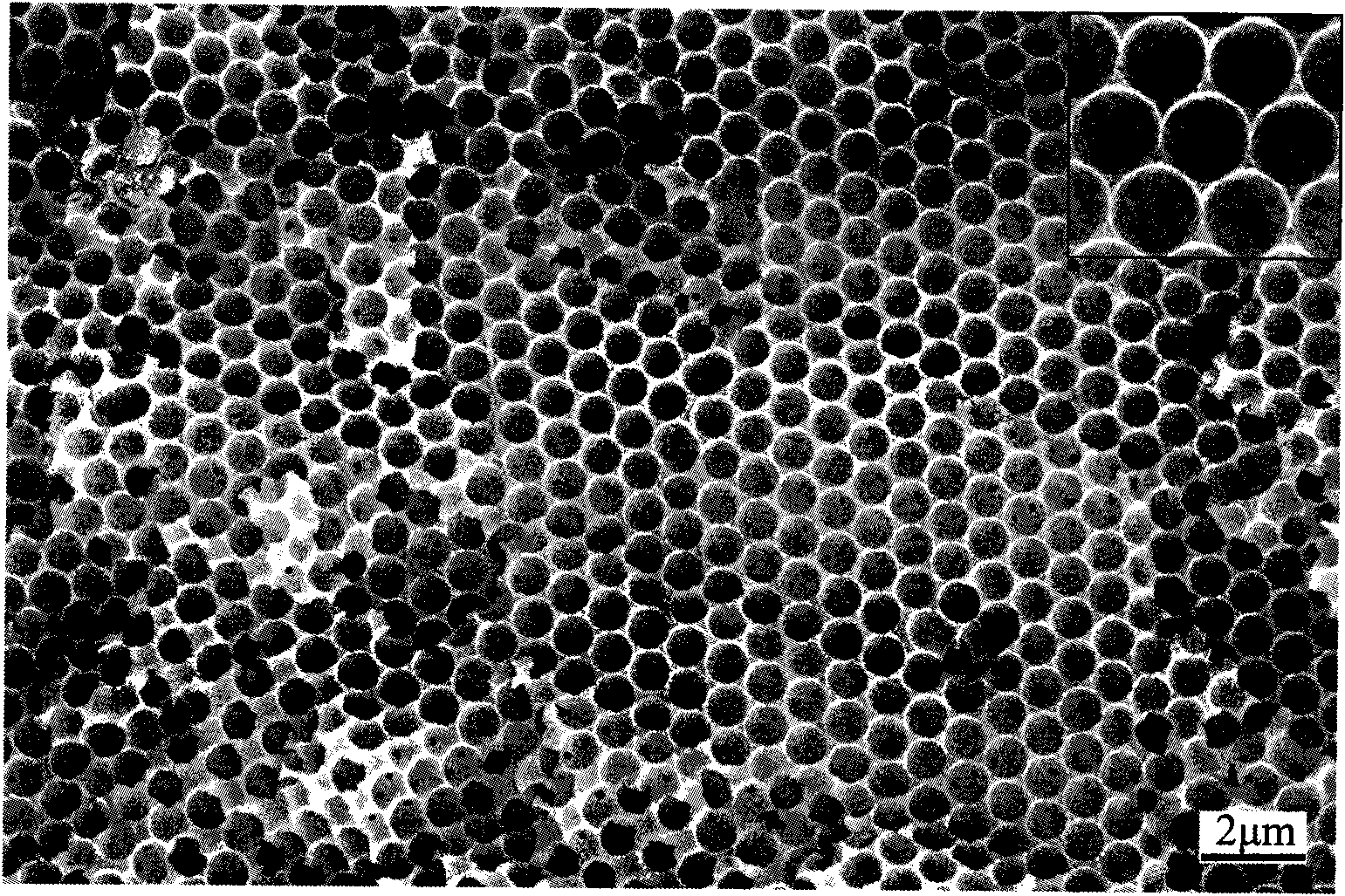

[0077] Preparation of 3DOM CLPS with an average pore size of 460 nm linked to 2-amino-5-methylthio-1,3,4-thiadiazole.

[0078] (1) Preparation of silica template

[0079] The preparation steps of the silica template refer to Example 1, and only the addition of reagents is adjusted: 13.8 g of absolute ethanol, 7.5 g of ammonia water with a percentage concentration of 25%, 12.5 g of distilled water, and 13.8 g of ethyl orthosilicate. A silica template with an average particle diameter of 460 nm was obtained.

[0080] (2) Preparation of three-dimensional ordered macroporous materials (3DOM)

[0081] After 0.0610mol styrene (6.35g), 0.0328mol divinylbenzene (4.27g) and 0.0531g diisopropyl peroxydicarbonate are fully dissolved in a 50mL beaker, the mixture is injected into the two mouths containing the sintered template. In the bottle, soak the template until transparent. Polymerize at 65°C for 2 hours and at 80°C for 24 hours to obtain a three-dimensional ordered polymer / silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com