Method for producing battery-grade lithium hydroxide by utilizing battery-grade lithium carbonate lithium-depositing mother liquid

A lithium precipitation mother liquor, lithium hydroxide technology, applied in the direction of lithium oxide;/hydroxide, etc., can solve the problems of complex technology, large steam consumption, large evaporation, etc., to achieve simple and practical process, high resource utilization rate , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

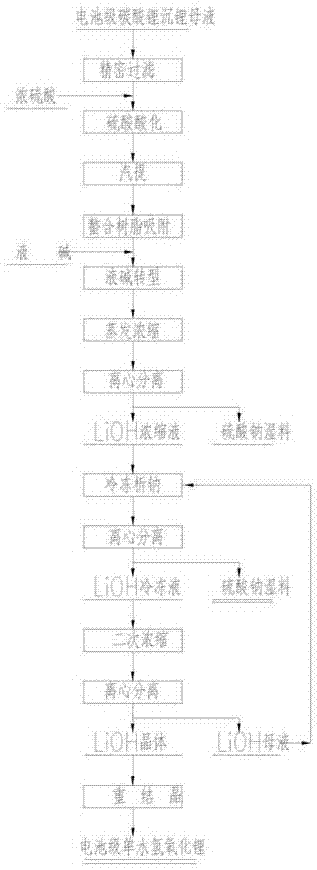

Image

Examples

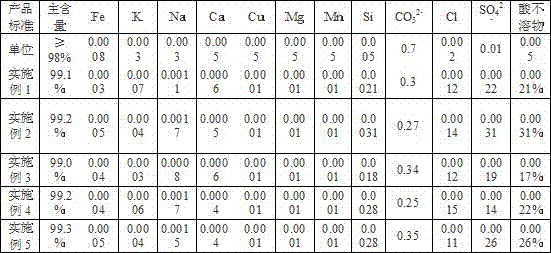

Embodiment 1

[0034] A, precision filtration: 10m 3 The battery-grade lithium carbonate lithium precipitation mother liquor is passed through a 1um precision filter to remove insoluble matter and obtain 10m 3 precision filter fluid;

[0035] B, sulfuric acid acidification: add the H of 98% (wt%) in the precision filtrate in step A 2 SO 4 35Kg, adjust the pH of the solution to 1, stir the reaction for 0.5h, and then pump the solution into the acid stripping tower (Hangzhou Jietian Environmental Protection Technology Co., Ltd., model JT-007) for deep CO removal 3 2- Ions, stripping temperature 60-100°C, operating pressure 0.1Mpa, stripping tower gas velocity 1.3m / s, to obtain acidified liquid;

[0036] C. Chelating resin to remove calcium and magnesium: pass the acidified solution obtained in step B through a chelating resin tower (Xi'an Lanxiao Technology New Materials Co., Ltd., model LSC-300) to remove Ca in the solution 2+ , Mg 2+ , the velocity of the control solution is 50m 3 / h,...

Embodiment 2

[0043] A, precision filtration: 10m 3 The battery-grade lithium carbonate lithium precipitation mother liquor is passed through a 2um precision filter to remove insoluble matter and obtain 10m 3 precision filter fluid;

[0044] B, sulfuric acid acidification: add the H of 60% (wt%) in the precision filtrate in step A 2 SO 4 54Kg, adjust the pH of the solution to 2, stir the reaction for 3 hours, and then pump the solution into the acid stripping tower (Hangzhou Jietian Environmental Protection Technology Co., Ltd., model JT-007) for deep removal of CO 3 2- Ions, stripping temperature 60-100°C, operating pressure 0.1Mpa, stripping tower gas velocity 1.3m / s, to obtain acidified liquid;

[0045] C. Chelating resin to remove calcium and magnesium: pass the acidified solution obtained in step B through a chelating resin tower (Xi'an Lanxiao Technology New Materials Co., Ltd., model LSC-300) to remove Ca in the solution 2+ , Mg 2+ , the velocity of the control solution is 120...

Embodiment 3

[0052] A, precision filtration: 10m 3 The battery-grade lithium carbonate lithium precipitation mother liquor is passed through a 3um precision filter to remove insoluble matter and obtain 10m 3 precision filter fluid;

[0053] B, sulfuric acid acidification: add the H of 98% (wt%) in the precision filtrate in step A 2 SO 4 33Kg, adjust the pH of the solution to 3, stir the reaction for 2 hours, and then pump the solution into the acid stripping tower (Hangzhou Jietian Environmental Protection Technology Co., Ltd., model JT-007) for deep CO removal 3 2- Ions, stripping temperature 60-100°C, operating pressure 0.1Mpa, stripping tower gas velocity 1.3m / s, to obtain acidified liquid;

[0054] C. Chelating resin to remove calcium and magnesium: pass the acidified solution obtained in step B through a chelating resin tower (Xi'an Lanxiao Technology New Materials Co., Ltd., model LSC-300) to remove Ca in the solution 2+ , Mg 2+ , the velocity of the control solution is 120m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com