Method for simultaneous removal and recovery of heavy metal ions and organic acid by using chelating resin

A technology of heavy metal ions and chelating resins, applied in chemical instruments and methods, ion exchange water/sewage treatment, water/sewage treatment, etc., can solve the problems of inability to recycle resources, high cost and low efficiency of compound polluted wastewater, and achieve Significant economic benefits, broad application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

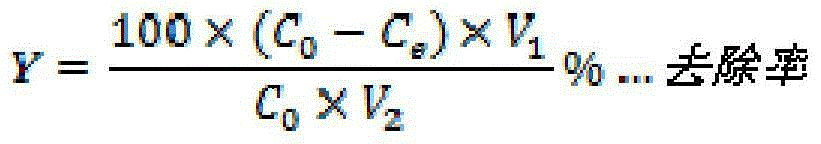

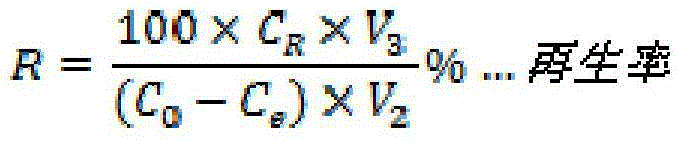

Method used

Image

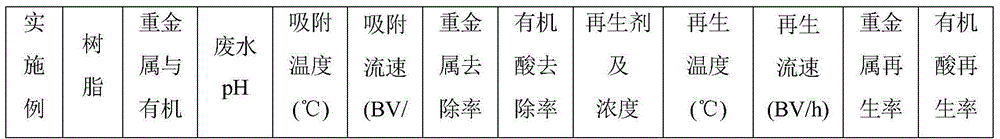

Examples

Embodiment 1

[0026] Put 2.0g (8.2mL wet volume) of resin A into a jacketed glass adsorption column (Φ32×360mm), keep the column temperature at 30°C, mix copper and citric acid waste water (the initial concentration of copper is 50mg / L, The initial concentration of citric acid is 100mg / L), and the pH is adjusted to 2.5, and is pumped into the adsorption column with a flow rate of 1BV / h, and the processing capacity is 100BV. The chelating resin after adsorption is desorbed and regenerated with 2% HCl solution by weight percentage, the desorption temperature is 5° C., and the flow rate is 1 BV / h. The desorbed and regenerated resin is washed to neutral with water and can be reused.

Embodiment 2

[0028] Put 2.0g (8.2mL wet volume) of resin A into a jacketed glass adsorption column (Φ32×360mm), keep the column temperature at 30°C, mix copper and citric acid waste water (the initial concentration of copper is 50mg / L, The initial concentration of citric acid is 100mg / L), and the pH is adjusted to 4.5, and is pumped into the adsorption column with a flow rate of 1BV / h, and the processing capacity is 100BV. The chelating resin after adsorption is desorbed and regenerated with 10% HCl solution by weight percentage, the desorption temperature is 30°C, and the flow rate is 10BV / h. After the desorption is completed, the resin is washed with water to neutrality and can be reused.

Embodiment 3

[0030] Put 2.0g (8.2mL wet volume) of resin A into a jacketed glass adsorption column (Φ32×360mm), keep the column temperature at 30°C, mix copper and citric acid waste water (the initial concentration of copper is 50mg / L, The initial concentration of citric acid is 100mg / L), and the pH is adjusted to 7.5, and is pumped into the adsorption column with a flow rate of 1BV / h, and the processing capacity is 100BV. The chelating resin after adsorption is desorbed and regenerated with 30% HCl solution by weight percentage, the desorption temperature is 50°C, and the flow rate is 20BV / h. After the desorption is completed, the resin is washed with water to neutrality and can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com