Preparation method of ion imprinted hydroxamic acid chelate resin

A chelating resin and ion imprinting technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as uneven distribution, limited resin adsorption performance, and low content of resin functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

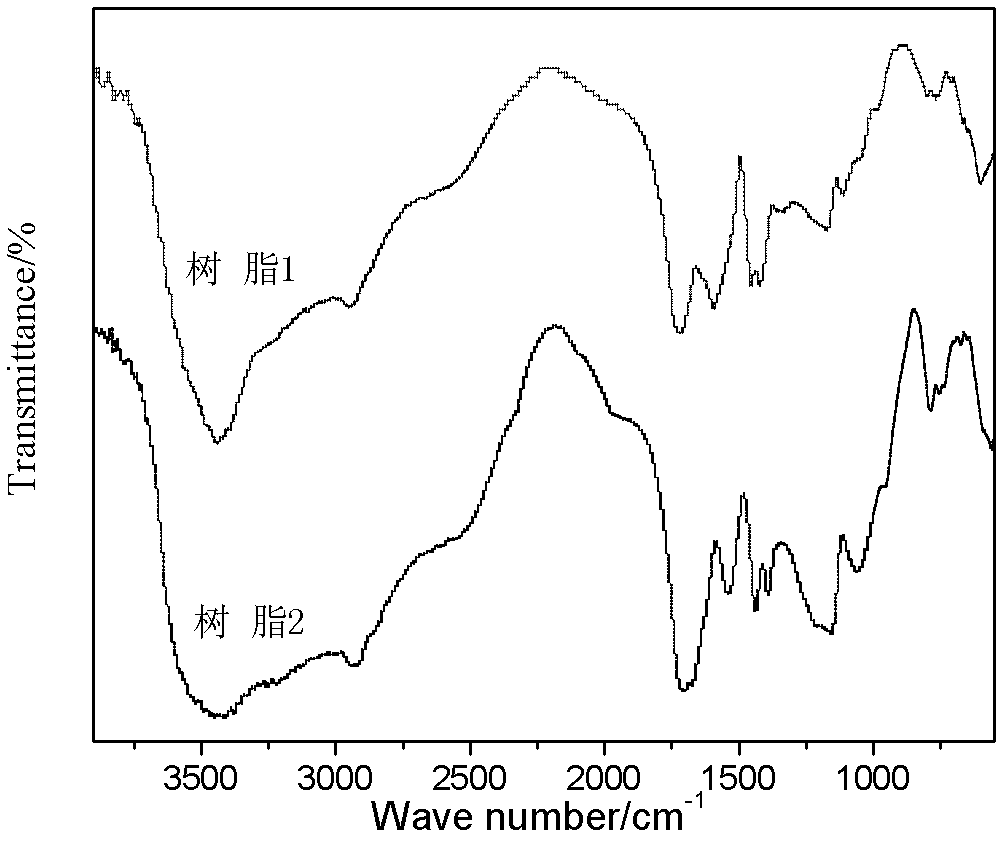

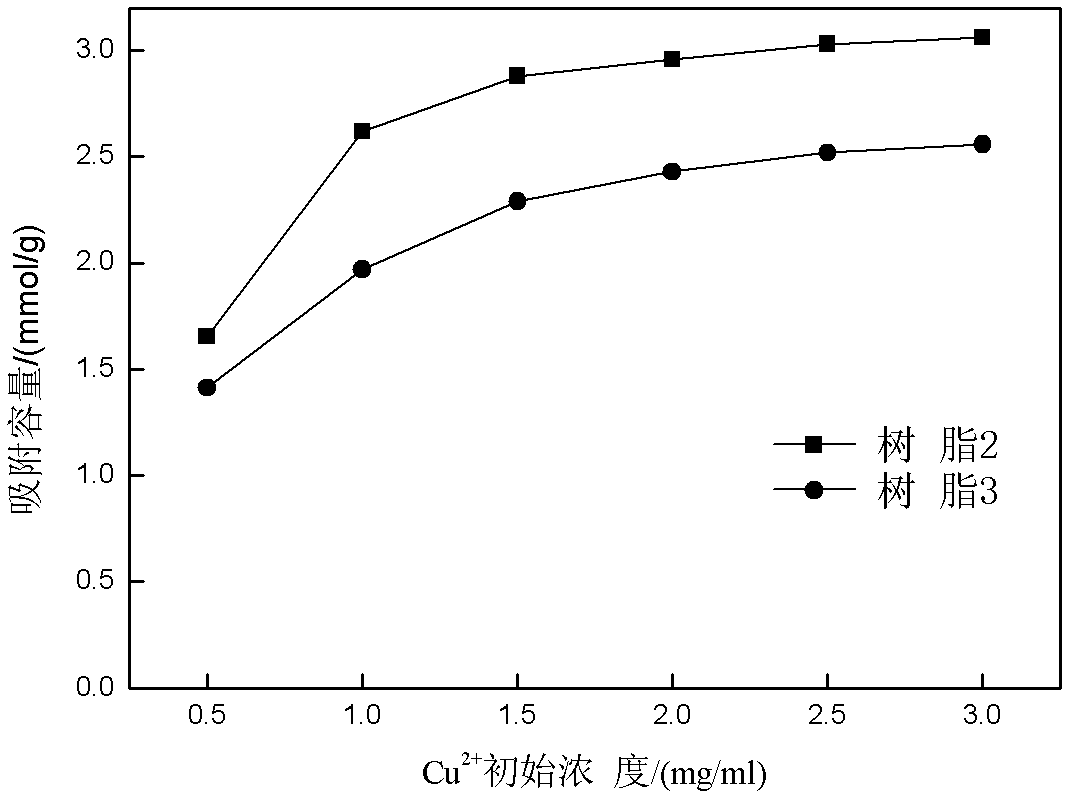

[0028] Example 1 Synthesis and adsorption performance of copper ion imprinted hydroxamic acid resin

[0029] Dissolve 0.12 mol of hydroxylamine hydrochloride and 0.20 mol of sodium hydroxide in 100 ml of a solution with a volume ratio of methanol to water of 1:1, then slowly add 0.1 mol of methyl acrylate into the solution, and control the reaction temperature at 60°C for 5 hours to obtain propylene hydroxamic acid solution. Use sulfuric acid to adjust the pH value of the solution to about 4, add 100ml of 0.20mol / L copper sulfate solution with a pH value of 4, and react at 30°C for 2h. Add 0.5 g of polyvinyl alcohol, 0.5 g of divinylbenzene and 0.5 g of benzoyl peroxide into the solution, and react at 60° C. for 3 h to obtain resin 1 . After filtering and washing with water, put the resin into a stoppered Erlenmeyer flask, add 50mL of 1mol / L sulfuric acid, shake at 40°C for 4h, filter, and dry at 60°C for 1h to obtain the copper ion imprinted hydroxamic acid resin (resin 2 )...

Embodiment 2

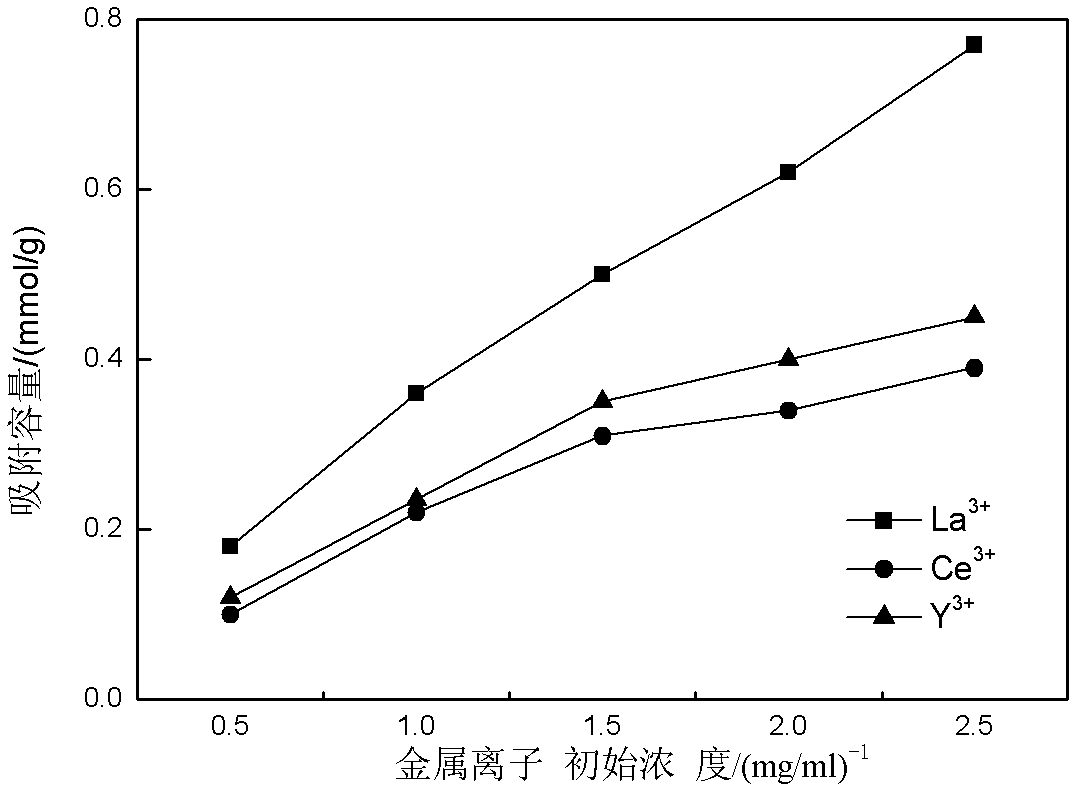

[0032] Example 2 Synthesis and adsorption performance of rare earth metal ion imprinted hydroxamic acid resin

[0033] The synthetic method of propenylhydroxamic acid is identical with embodiment 1. Use nitric acid to adjust the pH value of the solution to about 5, add 100ml of 0.20mol / L lanthanum nitrate, cerium nitrate or yttrium nitrate solution with a pH value of 5, and react at 30°C for 1h. Add 0.5g of polyvinyl alcohol, 0.01g of sodium dodecylbenzenesulfonate, 0.5g of divinylbenzene, 0.5g of styrene and 0.5g of benzoyl peroxide into the solution, and react at 60°C for 3 hours to obtain a resin . After filtering and washing with water, put the resin into a stoppered Erlenmeyer flask, then add 50mL of 1mol / L sulfuric acid, and shake at 40°C for 4h to obtain a rare earth metal ion imprinted hydroxamic acid chelating resin. Resins prepared with lanthanum, cerium, and yttrium as imprinted ions are designated as resin 4, resin 5, and resin 6, respectively.

[0034] Take 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com