Mesoporous chelate resin containing phosphorus-oxygen functional groups and method for separating and enriching uranium

An oxygen functional group, chelating resin technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. The operation is time-consuming and troublesome, and the effect of fast adsorption, strong selectivity and low cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

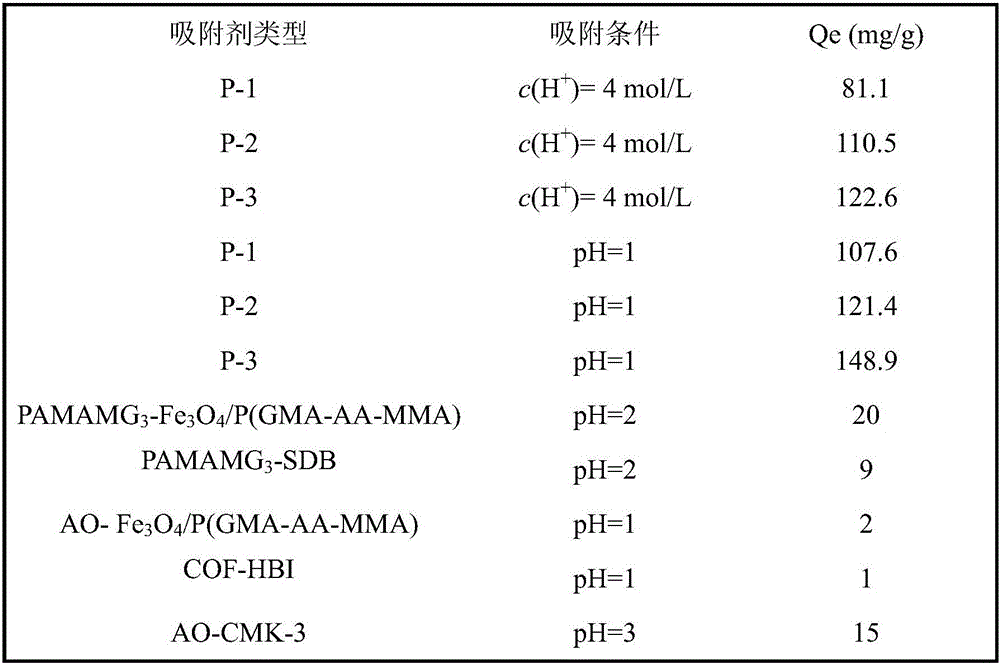

Embodiment 1

[0030] Mesoporous chelating resins containing phosphorus and oxygen functional groups can be prepared by solvothermal method. As a typical synthetic example: 1.5g of divinylbenzene (purity: 55%), 1.5g of vinylphosphonic acid and 0.05g of azobisisobutyronitrile were added to 5mL of ethyl acetate solvent, stirred at 25°C for 1h , put the above solution into a hydrothermal reaction kettle, react at 100°C for 24h, take it out, open the kettle, remove ethyl acetate by rotary evaporation, and dry it in vacuum at 45°C for 12h to obtain a mesoporous chelating resin containing phosphorus and oxygen functional groups 1.

Embodiment 2

[0032] Mesoporous chelating resins containing phosphorus and oxygen functional groups can be prepared by solvothermal method. As a typical synthesis example: 1.5g of ethylene glycol dimethacrylate, 1.5g of vinylphosphonic acid and 0.05g of azobisisobutyronitrile were added to 5mL of ethyl acetate solvent, stirred at 25°C for 1h, and Add the above solution into a hydrothermal reaction kettle, react at 100°C for 24 hours, take it out, open the kettle, remove ethyl acetate by rotary evaporation, and vacuum dry at 45°C for 12 hours to obtain mesoporous chelating resin 2 containing phosphorus and oxygen functional groups.

Embodiment 3

[0034] Mesoporous chelating resins containing phosphorus and oxygen functional groups can be prepared by solvothermal method. As a typical synthesis example: add 1.5g trimethylolpropane trimethacrylate, 1.5g vinylphosphonic acid and 0.05g azobisisobutyronitrile into 5mL ethyl acetate solvent, stir at 25°C for 1h , put the above solution into a hydrothermal reaction kettle, react at 100°C for 24h, take it out, open the kettle, remove ethyl acetate by rotary evaporation, and dry it in vacuum at 45°C for 12h to obtain a mesoporous chelating resin containing phosphorus and oxygen functional groups 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com