Novel chelate resin and production method and application thereof

A chelating resin, a new type of technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of polysilicon production and quality improvement, raw material manufacturers are uneven, and achieve simplified operation, reduced load, and large processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

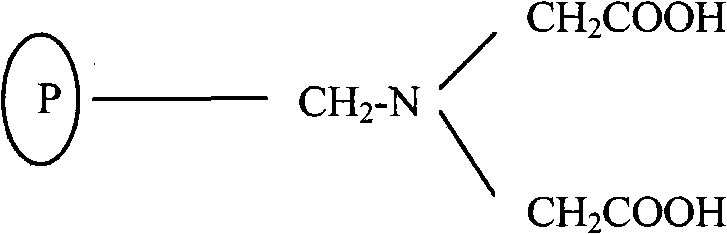

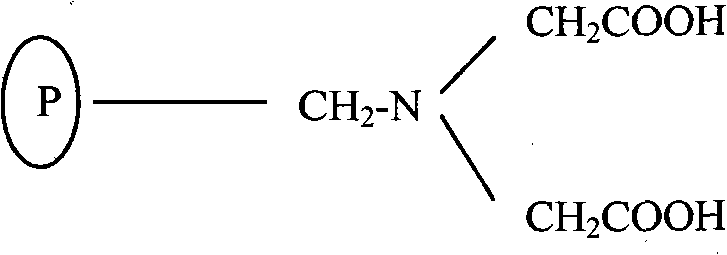

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 (preparation and boron removal effect of LX-100 chelating resin)

[0042] In a 1000 ml three-necked bottle, add 400 ml of water and dissolve 0.5% (volume ratio) of polyvinyl alcohol (polymerization degree is 1000-2000, alcoholysis degree is 80-90%) and 15% (volume ratio) of toluene. 0.5 gram of benzoyl peroxide was dissolved in the mixed solution of 82.5 gram of styrene and 17.5 gram of divinylbenzene (content 42%), then added in the three-necked bottle. Stirring was started (desktop stirring with a laboratory iron frame), and the temperature was raised to 45°C. Then heat up to 80°C in 1 hour, maintain for 2 hours, raise to 85°C, maintain for 2 hours, boil at 95-100°C for 6 hours. Then the balls are filtered out (funnel type ceramic filter, vacuum suction filtration), washed with acetone, dried (80-100 ℃ laboratory oven, until there is no free water), and sieved (nylon mesh, hand sieve) to obtain White balls of 0.3-1.0 mm diameter. Get 100 grams of whit...

Embodiment 2

[0045] Embodiment 2 (preparation and boron removal effect of LX-600 chelating resin)

[0046] In a 1000 ml three-necked bottle, add 400 ml of water and dissolve 0.5% (volume ratio) of polyvinyl alcohol (polymerization degree is 1000-2000, alcoholysis degree is 80-90%) and 15% (volume ratio) of toluene. 0.5 gram of benzoyl peroxide was dissolved in the mixed solution of 80 gram of styrene and 20 gram of divinylbenzene (content 42%), then added in the three-necked bottle. Stirring was started (desktop stirring with a laboratory iron frame), and the temperature was raised to 45°C. Then heat up to 80°C in 1 hour, maintain for 2 hours, raise to 85°C, maintain for 2 hours, boil at 95-100°C for 6 hours. Then the balls are filtered out (funnel type ceramic filter, vacuum suction filtration), washed with acetone, dried (80-100 ℃ laboratory oven, until there is no free water), and sieved (nylon mesh, hand sieve) to obtain White balls 0.3-1.0 mm in diameter. Take 100 grams of white b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| cross-linking degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com