Duprene rubber foamed sheet and preparation method thereof

A neoprene and foam sheet technology, applied in the field of polymer processing, can solve problems such as discontinuity in the production process, achieve strong continuity, high elongation, and reduce human resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

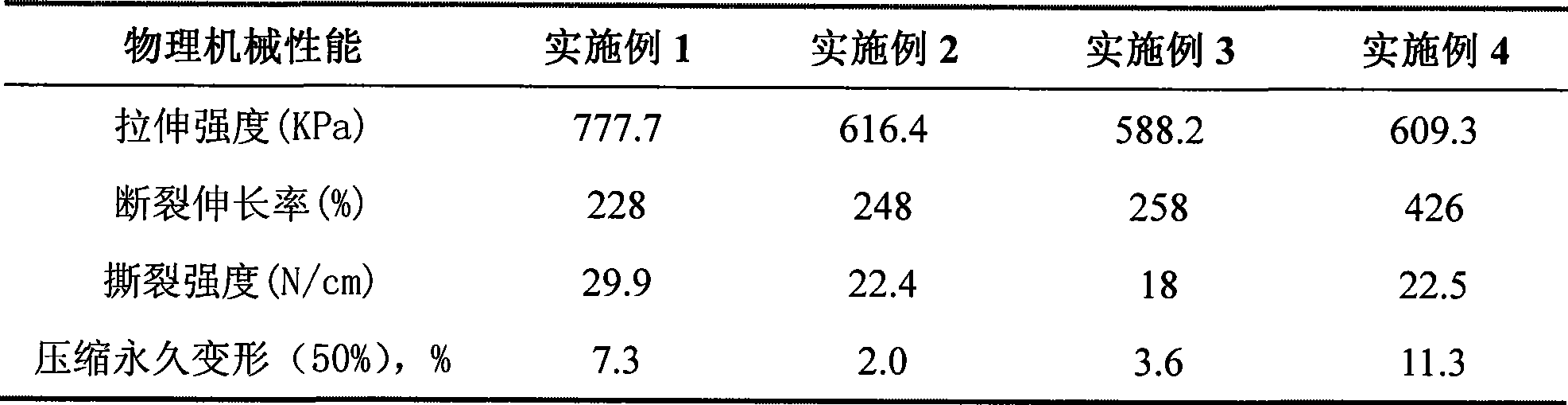

Examples

Embodiment 1

[0043] Formula: 100kg neoprene (CR), 10kg black ointment, 27kg carbon black, 1.3kg Aflux25, 3.3kg paraffin, 180kg kaolin, 20kg naphthenic oil, 33kg aromatic oil, 9.0kg dinitrosopentamethylene tetra Amine, 13kg zinc oxide, 6.7kg magnesium oxide, 1.2kg N,N'-diethylthiourea, 1.2kg ethylenethiourea, 4.7kg urea grease, 1.3kg dilauryl thiodipropionate, 2.0kg 2,2'-methylenebis(4-methyl-6-tert-butylphenol), 3.3kg petrolatum. step:

[0044] 1) Mix neoprene, black ointment, carbon black, dispersant, and paraffin in a pressurized kneader for 400s;

[0045] 2) Mix the mixed material for 400s on an open mill;

[0046] 3) Mix with other ingredients in a pressurized kneader for 400s in the order of powder, oil, and rubber;

[0047] 4) mixing the mixed material for 420s on the open mill, and feeding the extruder into sheets;

[0048] 5) Send the mixed material into the extruder to extrude and measure, so that the volume of the tablet is slightly larger than the volume of the mold frame of...

Embodiment 2

[0053] Formula: 100kg neoprene (CR), 13kg black ointment, 18kg carbon black, 1.0kg Aflux25, 2.8kg paraffin, 45kg calcium carbonate, 12kg naphthenic oil, 20kg aromatic oil, 9kg azodicarbonamide, 8.5kg oxidation Zinc, 5.7kg magnesium oxide, 0.7kg N,N'-diethylthiourea, 2.0kg dilauryl thiodipropionate, 1.3kg stearic acid, 2.0kg petrolatum.

[0054] step:

[0055] 1) Mix neoprene, black ointment, carbon black, dispersant, and paraffin in a pressurized kneader for 450s;

[0056] 2) Mix the mixed material for 350s on an open mill;

[0057] 3) Mix with other ingredients in a pressurized kneader for 450s in the order of powder, oil, and rubber;

[0058] 4) Mix the mixed material for 400s on an open mill, and feed the extruder into sheets;

[0059] 5) Send the mixed material into the extruder to extrude and measure, so that the volume of the tablet is slightly larger than the volume of the mold frame of the first molding foaming machine;

[0060]6) Send the extruded tablet to the fi...

Embodiment 3

[0064] Formula: 100kg neoprene (CR), 15kg black ointment, 18kg carbon black, 1.5kg Aflux25, 2.8kg paraffin, 45kg calcium carbonate, 12kg naphthenic oil, 20kg aromatic oil, 9kg azodicarbonamide, 8.5kg oxidation Zinc, 5.7kg magnesium oxide, 0.5kg N,N'-diethylthiourea, 2.0kg dilauryl thiodipropionate, 1.7kg stearic acid, 2.0kg petrolatum.

[0065] Step: with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com