Processing technique of quartz sand

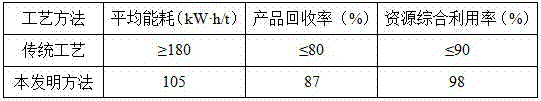

A processing technology, quartz sand technology, applied in grain processing and other directions, can solve the problems of backward quartz sand processing technology, high product energy consumption, low product recovery rate, etc. The effect of high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

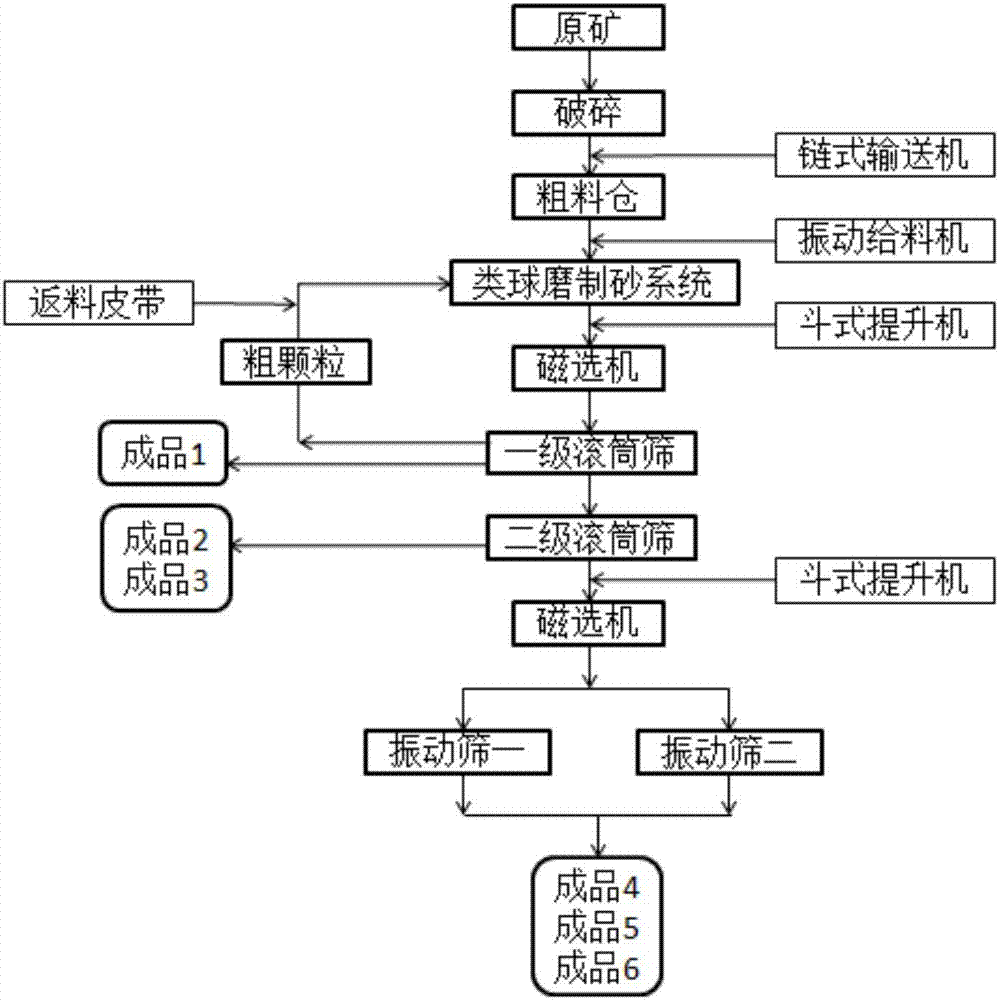

[0022] The specific implementation of this embodiment is as figure 1 As shown in the flow chart, the raw ore is powdered quartz, including crushing, sand making, screening and grading processes, of which:

[0023] The crushing process: the powdered quartz is crushed by a crusher, and the powdered quartz coarse material obtained by crushing is transported to the coarse material bin by a chain conveyor;

[0024] The sand-making process: the powdered quartz coarse particles in the coarse-grained bin are transported to the ball-milling sand-making system through a vibrating feeder, and the sand-making system performs the preparation of quartz sand;

[0025] The screening and grading process: the quartz sand is first transported to the magnetic separator by the bucket elevator, and enters the first-stage drum screen after iron removal is completed, and the coarse particles obtained by the screening are transported back to the sand making system by the return belt for secondary prod...

Embodiment 2

[0035] The specific implementation of this embodiment is as figure 1 As shown in the flow chart, the raw ore is yellow quartz, including crushing, sand making, screening and grading processes, of which:

[0036] The crushing process: the yellow quartz is crushed by a crusher, and the yellow quartz coarse material obtained by crushing is transported to the coarse material bin by a chain conveyor;

[0037] The sand-making process: the coarse yellow quartz particles in the coarse-grained bin are transported to the ball-milling sand-making system through a vibrating feeder, and the sand-making system prepares quartz sand;

[0038] The screening and grading process: the quartz sand is first transported to the magnetic separator by the bucket elevator, and enters the first-stage drum screen after iron removal is completed, and the coarse particles obtained by the screening are transported back to the sand making system by the return belt for secondary production. Sand, quartz sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com