Processing method for high-quality, low-sugar content plum slice

A processing method and low sugar content technology, applied in the confectionery industry, confectionery, food science, etc., can solve the problems of not meeting the needs of consumers, affecting hygiene and product quality, and circuitous product process, so as to achieve convenient and unified drying, The effect of avoiding nutrient loss, quality control and stable flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The operation process is as follows: salted fruit embryo → selection, cleaning → desalting → de-pitting → beating → seasoning → forming → drying → slicing → finished product packaging

[0022] Specific steps are as follows:

[0023] (1) Salted fruit embryos: Fresh plums (green plums) are selected to remove diseased and pest fruits and bad fruits, washed with water, immersed in salt water with a mass concentration of 20% and salted for 3 days to obtain salted fruit embryos.

[0024] (2) Selection and cleaning: Rinse the salted fruit embryos with clean water, remove the sundries, drain and pour them into the pool.

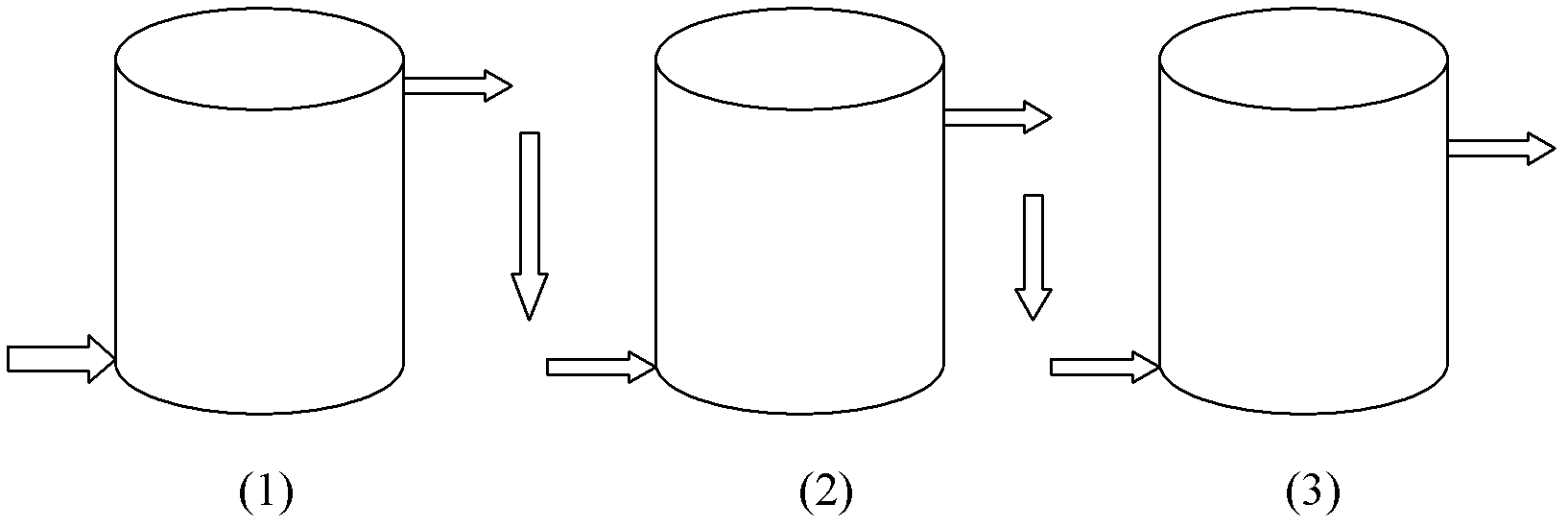

[0025] (3) Desalination: the desalination structure is as follows figure 1 As shown, the hot water inlet is set at the bottom of the pool, and the outlet is set at the top of the pool. The pump pumps 70-80°C hot water into pool 1, from pool 1 to pool 2, and from pool 2 to pool 3.

[0026] Under the hot water flowing state, pack the fruit embryos with a volum...

Embodiment 2

[0036] (1) Salted fruit embryos: Fresh plums (green plums) are selected to remove diseased and pest fruits and bad fruits, washed with water, immersed in salt water with a mass concentration of 15% and salted for 5 days to obtain salted fruit embryos.

[0037] (2) Selection and cleaning: Rinse the salted fruit embryos with clean water, remove the sundries, drain and pour them into the pool.

[0038] (3) Desalination: the desalination structure is as followsfigure 1 As shown, the pump pumps 70-80°C hot water into pool 1, flows from pool 1 into pool 2, and then flows from pool 2 into pool 3.

[0039] Under the hot water flowing state, pack the fruit embryos with a volume of 1 / 2 of the pool volume with a large-hole net and put them into pool 3; after about 2 hours, take them out with the net and put them into pool 2, and put the same amount of fruit embryos in the next batch into Pool 3; After about 2 hours, remove the fruit embryos in Pool 2 and put them in Pool 1, remove the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com