Powder product finishing production line

A production line and product technology, which is applied in the field of powder product processing, can solve problems such as inability to effectively position products, and achieve the effects of improving processing efficiency, high-efficiency processing, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

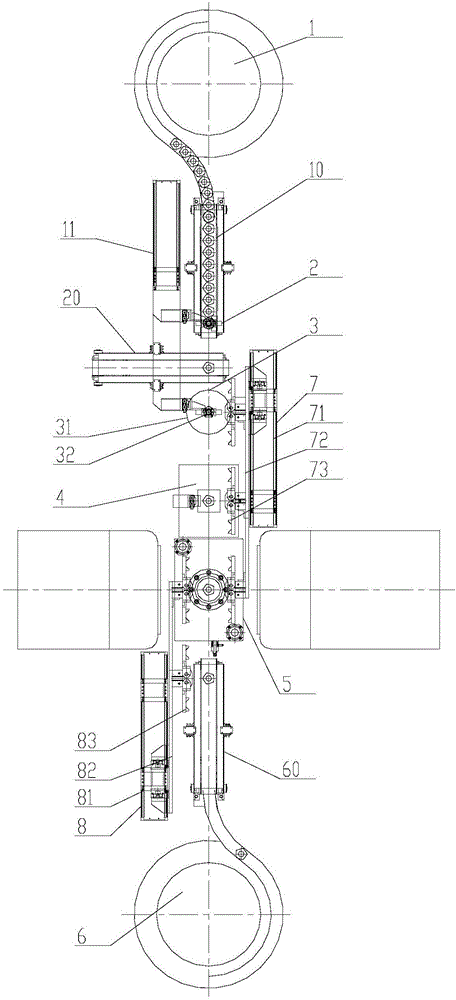

[0014] The invention is like figure 1 As shown, it includes a feeding device 1, a front and back recognition device 2, an image positioning device 3, an oil immersion device 4, a finishing machine 5, and a material receiving device 6 in sequence along the product feeding direction;

[0015] The feeding device 1 is connected to the side of the finishing machine 5 with a feeding conveyor belt 10, the positive and negative identification device 2 is fixedly connected to the feeding conveyor belt 10, between the feeding conveyor belt 10 and the image positioning device 3 A handling manipulator 11 is also provided; the material receiving device 6 is connected to the side of the finishing machine 5 with an unloading conveyor belt 60;

[0016] The finishing line also includes a feeding manipulator assembly 7 and a discharging manipulator assembly 8. The feeding manipulator assembly 7 includes a feeding rack 71, a feeding slide 72 and at least one feeding manipulator 73. The frame 71 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com