Mixed-substrate magnesium salt detergent of lubricating oil and preparation method of detergent

A technology of mixing matrix and lubricating oil, applied in the direction of lubricating composition, additive, petroleum industry, etc., to achieve the effect of good colloidal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

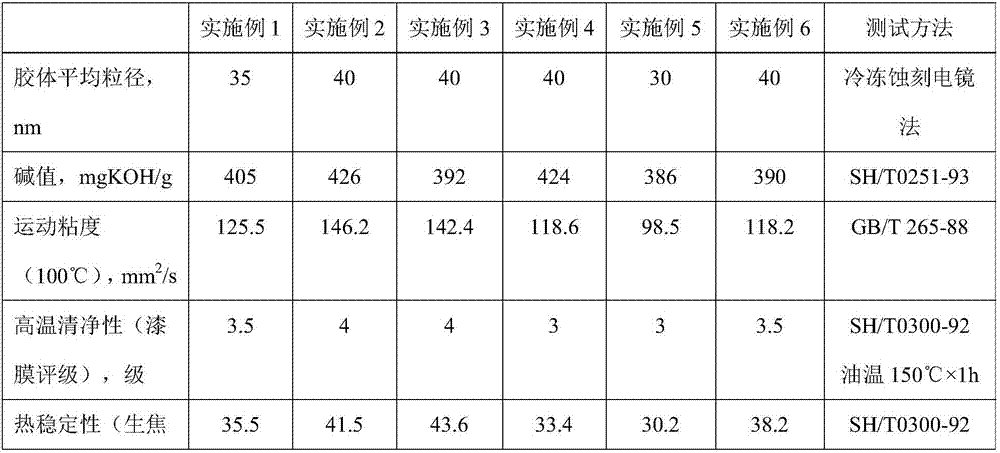

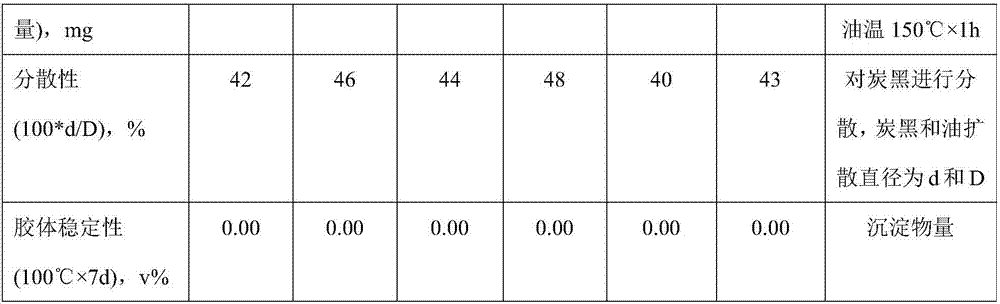

Examples

Embodiment 1

[0031] Activated magnesium oxide: produced by Shanghai Dunhuang Chemical Factory, with an activity of 60.

[0032] Ammonium petroleum sulfonate: produced by Yumen Petroleum Refinery and Chemical General Plant, the weight content of active ingredients is 48%, and the average relative molecular weight is 487.

[0033] Alkyl salicylic acid: produced by Additive Factory of Lanzhou Petrochemical Company, the weight content of active ingredients is 45%, and the average relative molecular mass is 354.

[0034] Using active magnesium oxide, ammonium petroleum sulfonate and alkyl salicylic acid as raw materials, the method for preparing a magnesium salt detergent for mixed matrix lubricating oil specifically comprises the following steps:

[0035] Step1: Add 80g ammonium petroleum sulfonate, 20g alkyl salicylic acid and 240ml diluent xylene to a three-necked flask equipped with a stirrer, reflux condenser, water separator and thermometer, stir and raise the temperature to 40°C .

[0...

Embodiment 2

[0041] Activated magnesium oxide: produced by Shanghai Dunhuang Chemical Factory, with an activity of 60.

[0042] Ammonium petroleum sulfonate: produced by Yumen Petroleum Refinery and Chemical General Plant, the weight content of active ingredients is 48%, and the average relative molecular weight is 487.

[0043] Alkyl salicylic acid: produced by Additive Factory of Lanzhou Petrochemical Company, the weight content of active ingredients is 45%, and the average relative molecular mass is 354.

[0044] Using active magnesium oxide, ammonium petroleum sulfonate and alkyl salicylic acid as raw materials, the method for preparing a magnesium salt detergent for mixed matrix lubricating oil specifically comprises the following steps:

[0045] Step1: Add 90g ammonium petroleum sulfonate, 10g alkyl salicylic acid and 240ml diluent xylene to a three-neck flask equipped with a stirrer, reflux condenser, water separator and thermometer, stir and raise the temperature to 40°C .

[004...

Embodiment 3

[0051] Activated magnesium oxide: produced by Shanghai Dunhuang Chemical Factory, with an activity of 60.

[0052] Ammonium petroleum sulfonate: produced by Yumen Petroleum Refinery and Chemical General Plant, the weight content of active ingredients is 48%, and the average relative molecular weight is 487.

[0053] Naphthenic acid: produced by Dushanzi Petrochemical General Plant, the weight content of active ingredients is 48%, and the average relative molecular weight is 342.

[0054] Using activated magnesium oxide, ammonium petroleum sulfonate and naphthenic acid as raw materials, the method for preparing a magnesium salt detergent for mixed matrix lubricating oil specifically comprises the following steps:

[0055] Step1: Add 80g petroleum ammonium sulfonate, 20g naphthenic acid and 240ml dilution solvent in the there-necked flask with stirrer, reflux condenser, water separator and thermometer, what this dilution solvent selects is that the distillation range is 80- Str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com