Mixed-alkene-participating preparation method of nonyl diphenylamine

A technology of nonyl diphenylamine and diphenylamine, which is applied in the field of nonyl diphenylamine preparation, and can solve the problem that the catalyst cannot be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

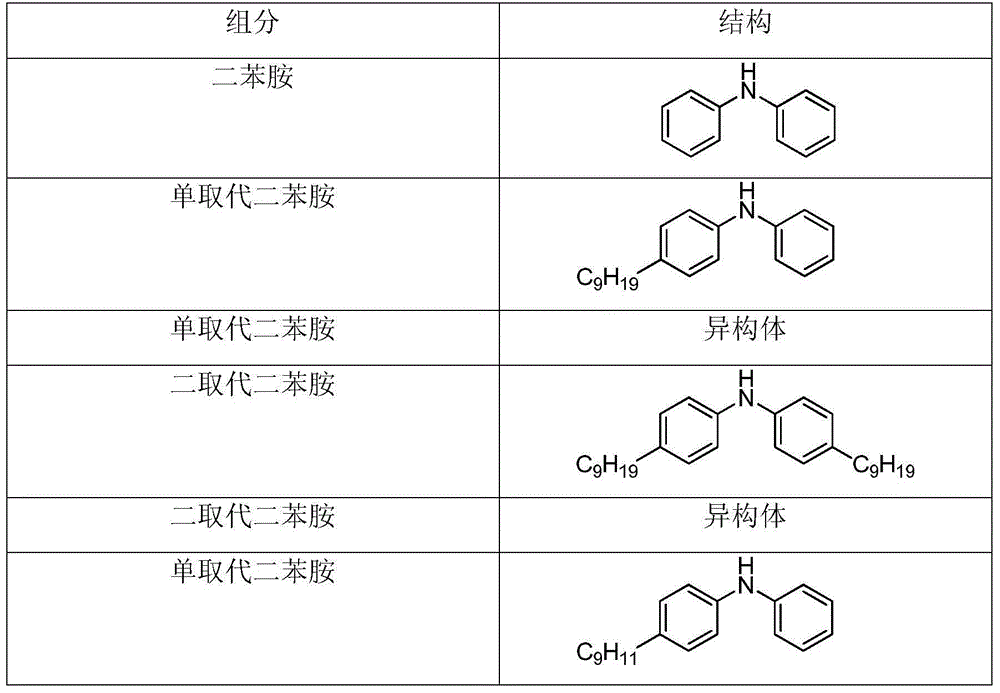

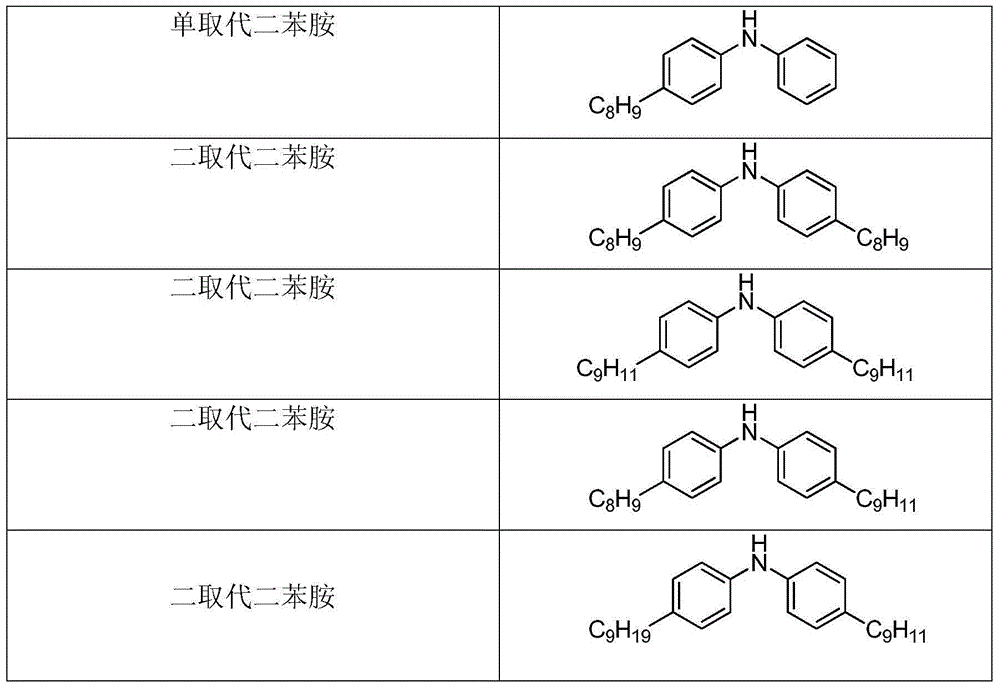

Image

Examples

Embodiment 1

[0037] Add 50.0 g of diphenylamine and 12.5 g of aluminum trichloride into a 500 ml glass container equipped with a stirrer, a thermometer, a heating mantle, a reflux condenser, a water separator, and a nitrogen pipeline, feed nitrogen, and melt at 80° C. Add 140g of C9 olefin to gradually increase the temperature to 148°C, stir with a magnetic stirrer, control the reflux speed and heating temperature, so that the temperature of the reactant is not lower than 130°C, and the reaction time is 14 hours. According to the TLC tracking reaction until the DPA content does not change, start vacuum distillation. After proper cooling, acid wash at 60°C, 5% NaOH alkali wash, water wash, silica gel decolorization, and vacuum distillation to obtain the final product and recover olefins. The content of diphenylamine in the product measured by chromatography is 6%, and the base number is 76.5.

Embodiment 2

[0039] Add 50.0 g of diphenylamine and 5.0 g of montmorillonite and active Al in a 500 ml glass container equipped with a stirrer, thermometer, heating mantle, reflux condenser, water separator, and nitrogen pipeline 2 o 3Catalyst, feed nitrogen, after melting completely at 80°C, add 32.6g C9 olefins and gradually increase the temperature to 155°C, after the temperature stabilizes, continue to add 70.0g olefins within 5 hours, the amount of polymerization inhibitor added is 40ppm, controlled The reaction temperature cannot be lower than 145°C, and the reaction time is 16 hours. According to TLC follow-up reaction when DPA content no longer changes, continue to add 20g styrene to react for 4 hours, start vacuum distillation, after proper cooling. Then carry out vacuum distillation, and finally filter at 60°C to obtain the final product, recover olefins and catalysts to continue the reaction. According to chromatographic analysis, the remaining amount of diphenylamine is not m...

Embodiment 3

[0041] Add 50.0 g of diphenylamine and 5.0 g of montmorillonite and active Al in a 500 ml glass container equipped with a stirrer, thermometer, heating mantle, reflux condenser, water separator, and nitrogen pipeline 2 o 3 The catalyst is fed with nitrogen, and after it is completely melted at 80°C, add 32.6g of C9 olefins and gradually raise the temperature to 155°C. After the temperature stabilizes, continue to add 70.0g of olefins within 5 hours, and control the reaction temperature not lower than 145°C. The reaction time was 16 hours. According to the TLC tracking reaction until the DPA content does not change, continue to add 24g of α-methylstyrene to react for 4 hours (this active olefin needs to be added carefully, the product is easy to form a solid), start vacuum distillation, after cooling properly. Then carry out vacuum distillation, and finally filter at 60°C to obtain the final product, recover olefins and catalysts to continue the reaction. According to the chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com