Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

A technology of calcium alkylbenzenesulfonate and alkylbenzenesulfonic acid, which is applied in the preparation of sulfonic acid, lubricating compositions, additives, etc., and can solve the problems of high production cost and product price, long production cycle, and low product yield , to achieve the effects of guaranteed quality and performance, low production and processing costs, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

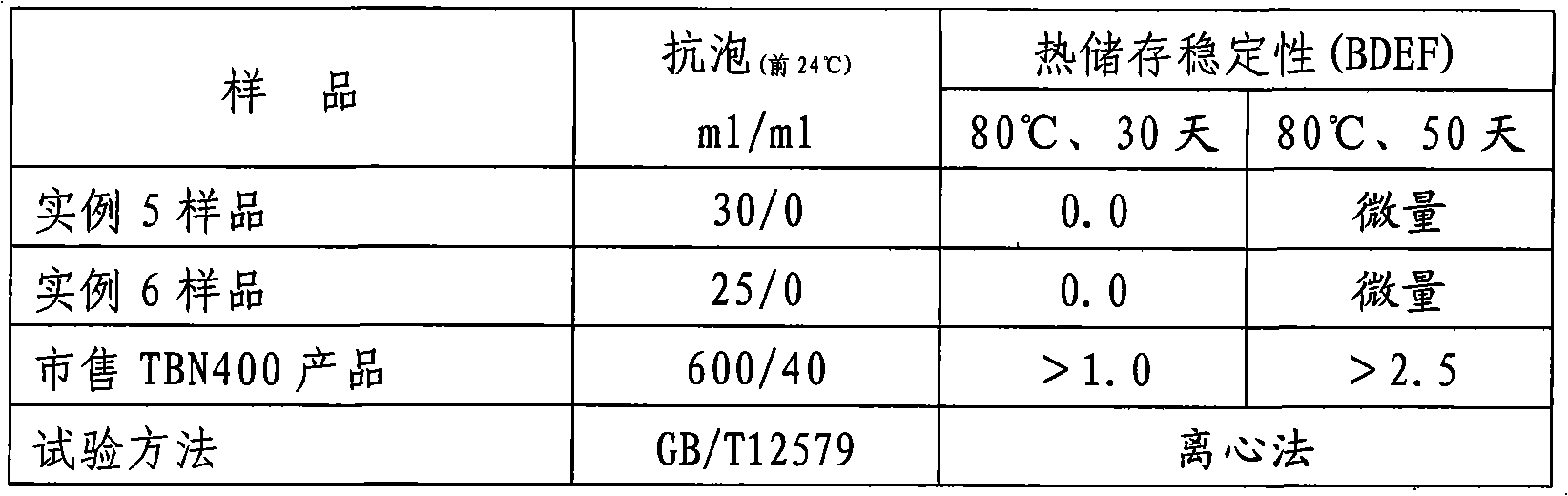

Examples

example 1

[0023] Adopt the mixed sulfonic acid of long-chain linear alkylbenzene sulfonic acid and high boiler heavy alkylbenzene sulfonic acid as main raw material, described long-chain linear alkylbenzene sulfonic acid is long-chain (C 18 -C 26 ) linear alkylbenzene sulfonic acid, the carbon atoms of its alkyl chain are from C18 to C26, according to the mass ratio of long chain (C 18 -C 26 ) active matter content of linear alkylbenzene sulfonic acid is 85%, free acid content is 0.1%, average molecular weight is 480, according to mass ratio long chain (C 18 -C 26 ) The content of monosubstituted alkylbenzenesulfonic acid in the linear alkylbenzenesulfonic acid is 85%. Long-chain linear alkylbenzene sulfonic acid is preferably long-chain (C 20 -C 24 ) linear alkylbenzene sulfonic acid, that is, long-chain linear alkylbenzene sulfonic acid with a mass ratio of 85% of the sulfonic acid components of carbon 20, carbon 22 to carbon 24 in the alkyl side chain Acid, wherein the mass rat...

example 2

[0026] Adopt the mixed sulfonic acid of long-chain linear alkylbenzene sulfonic acid and high boiler heavy alkylbenzene sulfonic acid as main raw material, described long-chain linear alkylbenzene sulfonic acid is long-chain (C 18 -C 26 ) linear alkylbenzene sulfonic acid, the carbon atoms of its alkyl chain are from C18 to C26, which should be based on the mass ratio of the long chain (C 18 -C 26 ) active matter content of linear alkylbenzene sulfonic acid is 99.9%, free acid content is 0.5%, average molecular weight is 560, according to mass ratio long chain (C 18 -C 26 ) The content of monosubstituted alkylbenzenesulfonic acid in linear alkylbenzenesulfonic acid is 99.9%. Long-chain linear alkylbenzene sulfonic acid is preferably long-chain (C 20 -C 24 ) linear alkylbenzenesulfonic acid, that is, long-chain linear alkylbenzenesulfonic acid with a mass ratio of 99.9% of the sulfonic acid components of carbon 20, carbon 22 to carbon 24 in the alkyl side chain Acid, wher...

example 3

[0029] Adopt the mixed sulfonic acid of long-chain linear alkylbenzene sulfonic acid and high boiler heavy alkylbenzene sulfonic acid as main raw material, described long-chain linear alkylbenzene sulfonic acid is long-chain (C 18 -C 26 ) linear alkylbenzene sulfonic acid, the carbon atoms of its alkyl chain are from C18 to C26, which should be based on the mass ratio of the long chain (C 18 -C 26 ) active matter content of linear alkylbenzene sulfonic acid is 92%, free acid content is 0.3%, average molecular weight is 520, according to mass ratio long-chain (C 18 -C 26 ) The monosubstituted alkylbenzenesulfonic acid content in the linear alkylbenzenesulfonic acid is 93%. Long-chain linear alkylbenzene sulfonic acid is preferably long-chain (C 20 -C 24 ) linear alkylbenzene sulfonic acid, that is, long-chain linear alkylbenzene sulfonic acid with a mass ratio of 92% of the sulfonic acid components of carbon 20, carbon 22 to carbon 24 in the alkyl side chain Acid, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com