Heavy-loading CNG natural gas engine oil complexing agent and preparation method and application thereof

An engine oil and natural gas technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve problems such as environmental protection and energy saving requirements not meeting strict requirements, engine valves and valve seats being easily worn, and filters being easily blocked by sludge. , to achieve the effects of excellent high temperature detergency and low temperature dispersion performance, engine protection, and excellent acid neutralization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh raw materials:

[0039] Phosphobioctyl basic zinc salt 8kg;

[0040] Synthetic calcium sulfonate with ultra-alkaline value 14kg;

[0041] Alkylated diphenylamine 4.5kg;

[0042] Thioaminoester 9kg;

[0043] 3kg of synthetic magnesium sulfonate with ultra-alkaline value;

[0044] High molecular weight ashless dispersant 48kg;

[0045] Monoalkenyl succinimide 18kg.

[0046] The Zn content of the phosphobisoctyl basic zinc salt is 8.0-10.5%, the P content is 6.5-8.8%, and the S content is 12-18%. The calcium content of the super-basic value synthetic calcium sulfonate is ≥ 14m%, and the total base value is ≥ 395 mgKOH / g. The Mg content of the ultra-basic value synthetic magnesium sulfonate is ≥8.5%, and the total base value is ≥395mgKOH / g. The polymer ashless dispersant is high molecular weight polyisobutenyl succinimide, and the N content of the polymer ashless dispersant is 1.0-1.1%.

[0047] The raw materials are added into the blending kettle according to...

Embodiment 2

[0049] Weigh raw materials:

[0050] Phosphobioctyl basic zinc salt 10.5kg;

[0051] 11kg of synthetic calcium sulfonate with ultra-alkaline value;

[0052] Alkylated diphenylamine 6.5kg;

[0053] Thioaminoester 7kg;

[0054] 5.5kg of synthetic magnesium sulfonate with ultra-alkaline value;

[0055] High molecular weight ashless dispersant 43kg;

[0056] Monoalkenyl succinimide 22.5kg.

[0057] The Zn content of the phosphobisoctyl basic zinc salt is 8.0-10.5%, the P content is 6.5-8.8%, and the S content is 12-18%. The calcium content of the super-basic value synthetic calcium sulfonate is ≥ 14m%, and the total base value is ≥ 395 mgKOH / g. The Mg content of the ultra-basic value synthetic magnesium sulfonate is ≥8.5%, and the total base value is ≥395mgKOH / g. The polymer ashless dispersant is high molecular weight polyisobutenyl succinimide, and the N content of the polymer ashless dispersant is 1.0-1.1%.

[0058] The raw materials are added into the blending kettle ac...

Embodiment 3

[0060] Weigh raw materials:

[0061]Phosphobioctyl basic zinc salt 9kg;

[0062] Synthetic calcium sulfonate with ultra-alkaline value 12kg;

[0063] Alkylated diphenylamine 5kg;

[0064] Thioaminoester 8kg;

[0065] Ultra-alkaline synthetic magnesium sulfonate 4kg;

[0066] High molecular weight boronated ashless dispersant 45kg;

[0067] Monoalkenyl succinimide 20kg.

[0068] The raw materials are added into the blending kettle according to the weight ratio, the temperature is raised to 65° C., stirred for 2.5 hours under normal pressure, and filtered to obtain the heavy-duty CNG natural gas engine oil compounding agent.

[0069] The natural gas engine oil composite agent of table 1 embodiment 3, its quality index is as table 1:

[0070] Table 1

[0071]

[0072]

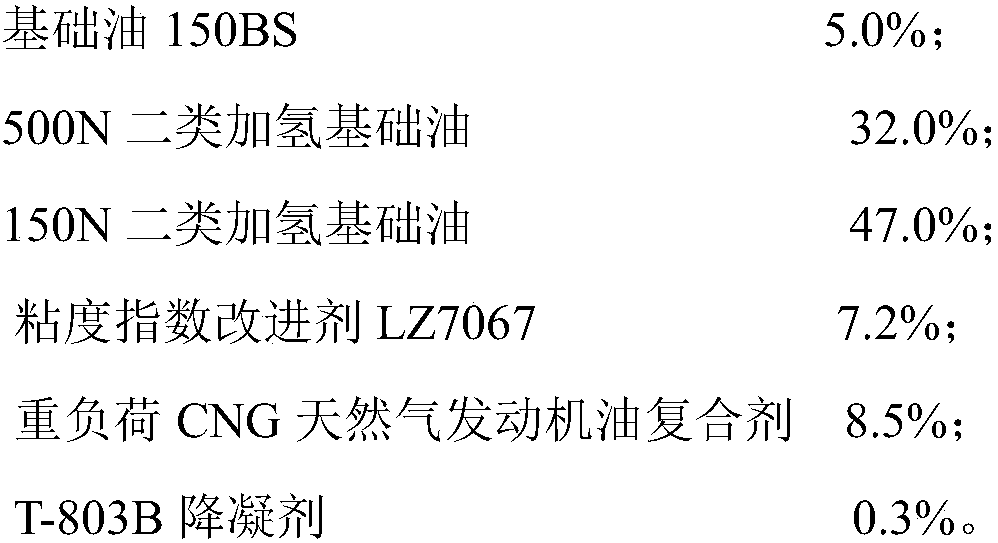

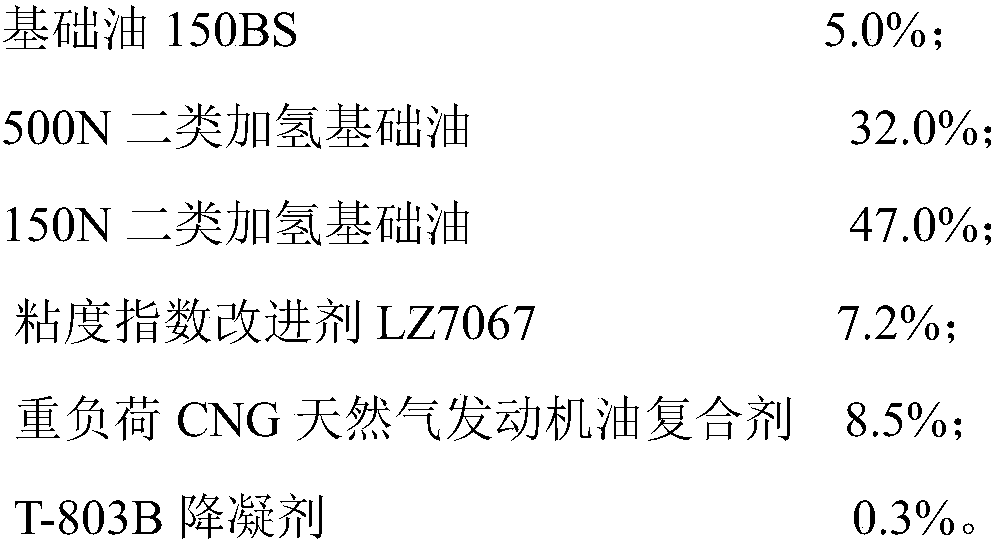

[0073] The heavy-duty CNG natural gas engine oil compounding agent deployment oil product of embodiment 3 of the present invention:

[0074] Oil quality grade and viscosity grade: API CNG SAE 15W / 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com