Method for preparing liquidized butyl diphenylamine/octyl diphenylamine

An octyldiphenylamine, liquefaction technology, used in the preparation of amino compounds from amines, organic chemistry, chemical recovery, etc., can solve the problems of unstable temperature, complicated recrystallization steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

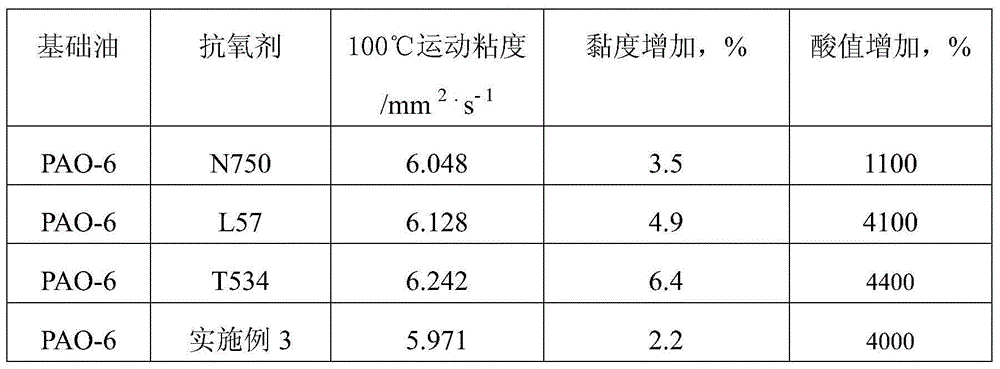

Examples

Embodiment 1

[0045] Add 128.8g of diphenylamine, 6.5g of catalyst and 75.0g of C8 olefins into a 500ml glass container equipped with a stirrer, thermometer, heating mantle, reflux condenser, water separator, and nitrogen pipeline, pass into nitrogen protection, and use a magnetic stirrer Stir, after melting at 80°C, gradually increase the temperature to 165°C, add 104g C8 olefin in 5-7 hours, control the reflux speed and heating temperature, so that the temperature of the reactant is not lower than 145°C, and the reaction time is 14 hours . According to the TLC tracking reaction until the DPA content does not change, it is properly cooled at 60 ° C and filtered, and the olefins are removed by vacuum distillation to obtain the final product. The olefins and catalyst are recovered. The product is a yellow clear liquid. The gas chromatography data shows that the content of diphenylamine is 5%, and the base number 122.

Embodiment 2

[0047] Add 128.8g of diphenylamine, 13g of catalyst and 75.0g of C8 olefin in a 500ml glass container equipped with stirrer, thermometer, heating mantle, reflux condenser, water separator, and nitrogen pipeline, pass into nitrogen protection, and add amount of polymerization inhibitor Stir with a magnetic stirrer, and after melting at 80°C, gradually increase the temperature to 155°C, add 104g of C8 olefin in 5 to 7 hours, control the reflux speed and heating temperature, so that the temperature of the reactant is not lower than 145 °C, and the reaction time was 14 hours. According to the TLC tracking reaction until the DPA content no longer changes, add 13g of polyisobutene, continue to react for 2 hours, after proper cooling, filter at 60°C, remove olefins by vacuum distillation to obtain the final product, recover olefins and catalyst, the product is yellow clear liquid, Gas chromatographic data showed a diphenylamine content of 1% and a base number of 166.

Embodiment 3

[0049] Add 128.8g of diphenylamine, 13g of catalyst and 179.0g of C8 olefin in a 500ml glass container equipped with stirrer, thermometer, heating mantle, reflux condenser, water separator, and nitrogen pipeline, pass into nitrogen protection, and add amount of polymerization inhibitor Stir with a magnetic stirrer. After melting at 80°C, gradually increase the temperature to 155°C. Control the reflux rate and heating temperature so that the temperature of the reactant is not lower than 145°C. The reaction time is 16 hours. According to the TLC tracking reaction until the DPA content does not change, add 25g of polyisobutene and continue the reaction for 2 hours. After proper cooling, filter at 60°C and remove the olefins by vacuum distillation to obtain the final product. Recover the olefins and catalyst. The product is an orange clear liquid. Gas chromatographic data showed a diphenylamine content of 2% and a base number of 162.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com