Hard-water-resisting semi-synthetic metal processing fluid and preparation method thereof

A metalworking fluid, semi-synthetic technology, used in the petroleum industry, lubricating compositions, base materials, etc., can solve the problems of lack of softening, excessive foaming of cutting fluid, pitting on the surface of workpieces and machine tools, and achieve outstanding hard water resistance. Effects of rust, long-term pH stability, good rust resistance and corrosion inhibition

Pending Publication Date: 2018-08-24

超滑科技(佛山)有限责任公司

View PDF12 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the service life of the processing fluid becomes longer, with the evaporation of water during processing, more Ca will be enriched. 2+ , Mg 2+ , thus forming a vicious circle, which cannot really solve the problem fundamentally

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

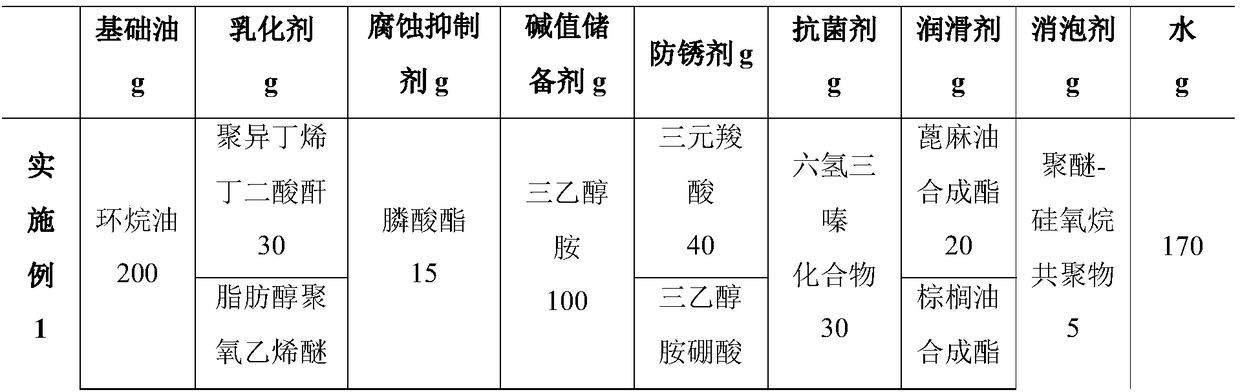

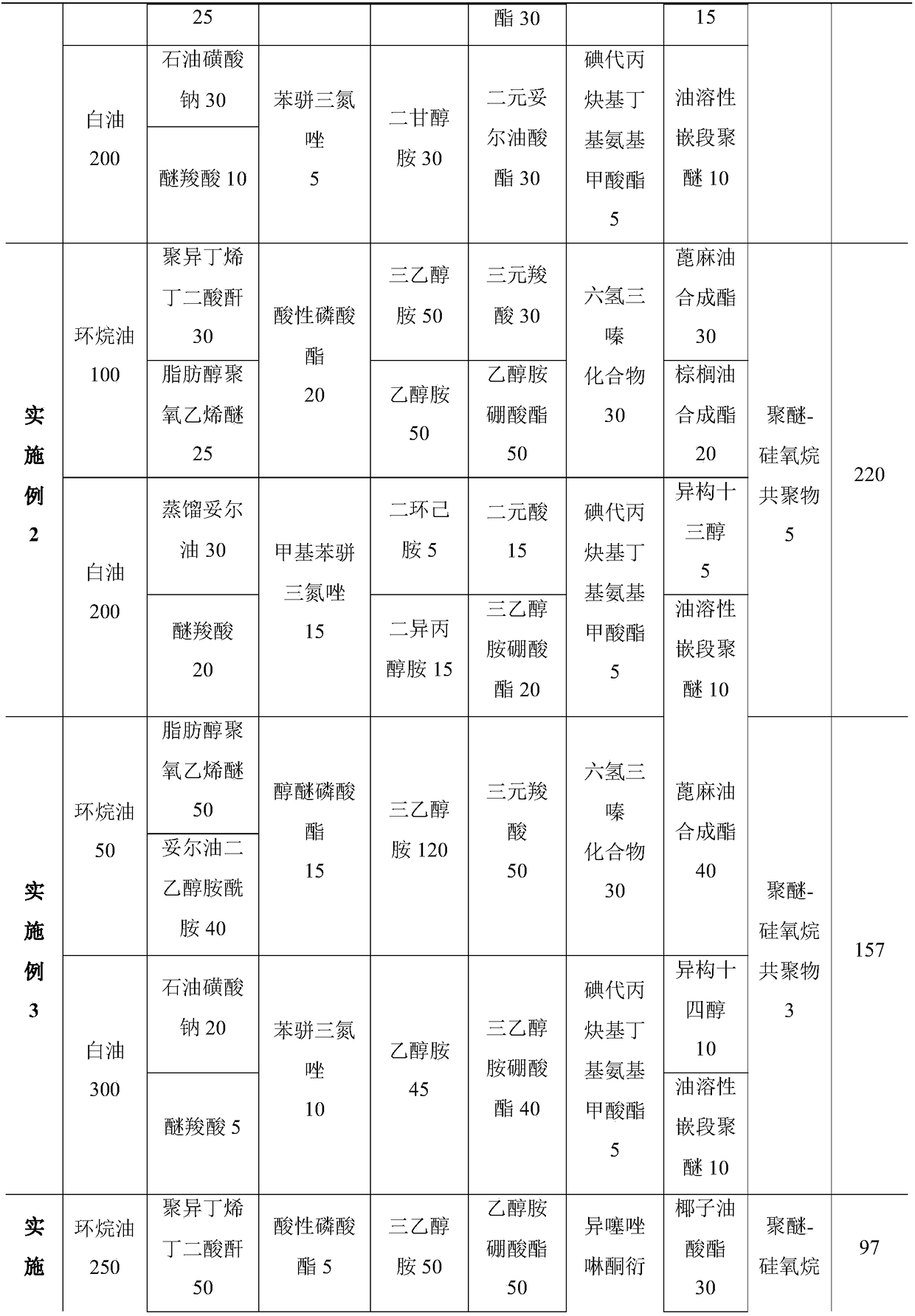

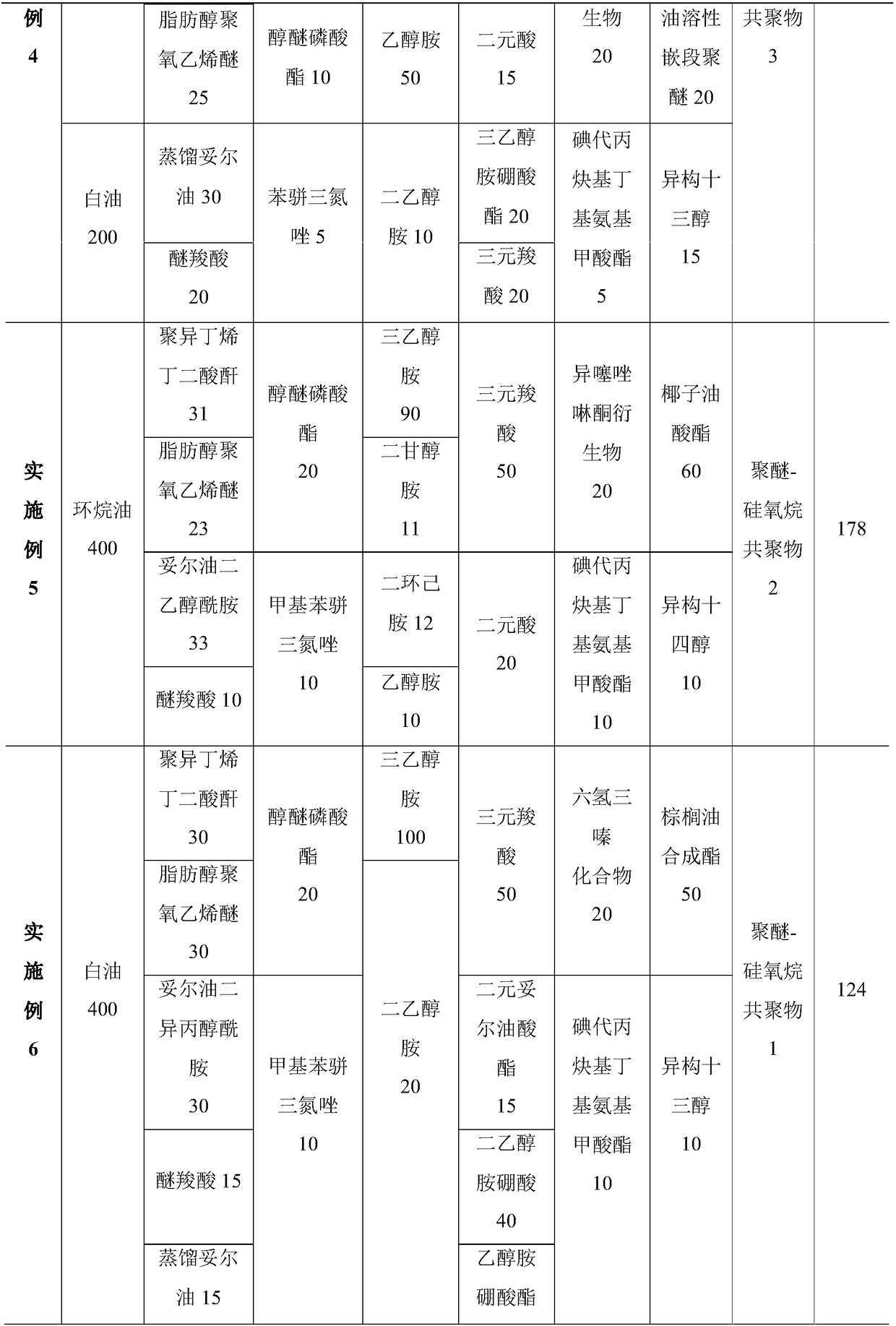

Embodiment 1~6

[0048] Table 1 Embodiment 1~6 anti-hard water semi-synthetic metalworking fluid composition

[0049]

[0050]

[0051]

[0052]

[0053] All the dibasic acids involved in the above examples 1-6 are sebacic acid, and all the tribasic acids involved in the examples 1-5 are BASF L190.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides hard-water-resisting semi-synthetic metal processing fluid and a preparation method thereof. The hard-water-resisting semi-synthetic metal processing fluid is prepared from thefollowing components in parts by weight: 25 to 60 parts of basic oil, 3 to 20 parts of emulsifier, 3 to 20 parts of antirust agent, 2 to 6 parts of corrosion inhibitor, 5 to 30 parts of alkali value storage agent and 8 to 40 parts of water. The hard-water-resisting semi-synthetic metal processing fluid provided by the invention has the advantages of good hard water stability and excellent antirustperformance, safe and odorless working environment and no irritation on human body skin and respiratory tracts.

Description

technical field [0001] The invention belongs to the field of metal working fluids, in particular to a semi-synthetic metal working fluid with high hard water stability and high hard water rust resistance. Background technique [0002] Metalworking fluid refers to the lubricating cooling medium used in the metalworking process, and is an important supporting material in the metalworking process. Metalworking fluid has the functions of lubrication, cooling, rust prevention and cleaning, etc., which can effectively prolong the service life of tools, prevent metal parts and machine tools from rusting, and take away the heat generated during processing, and effectively remove chips and dust on the surface of parts and tools , thereby improving processing quality and increasing production efficiency. [0003] During the use of metalworking fluids, due to the enrichment effect such as water evaporation, the water hardness of the machining fluid system will gradually increase, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10M173/00C10M111/02C10N30/06C10N30/12C10N30/16C10N40/20

CPCC10M111/02C10M169/044C10M173/00C10M2203/1006C10M2207/163C10N2030/06C10N2030/12C10N2030/16C10N2030/40C10N2030/41C10N2030/43C10N2030/64C10N2040/20C10N2020/02

Inventor 张宇飞刘腾飞戴媛静张晨辉雒建斌

Owner 超滑科技(佛山)有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com