Engine lubricating oil composition

A kind of lubricating oil composition, technology of diesel engine, applied in the field of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

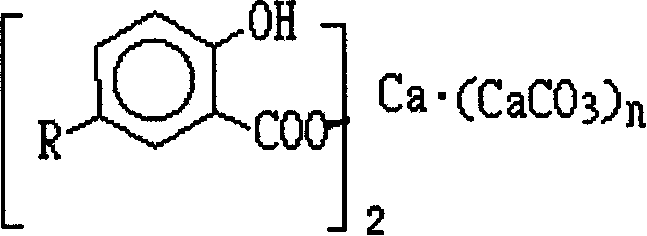

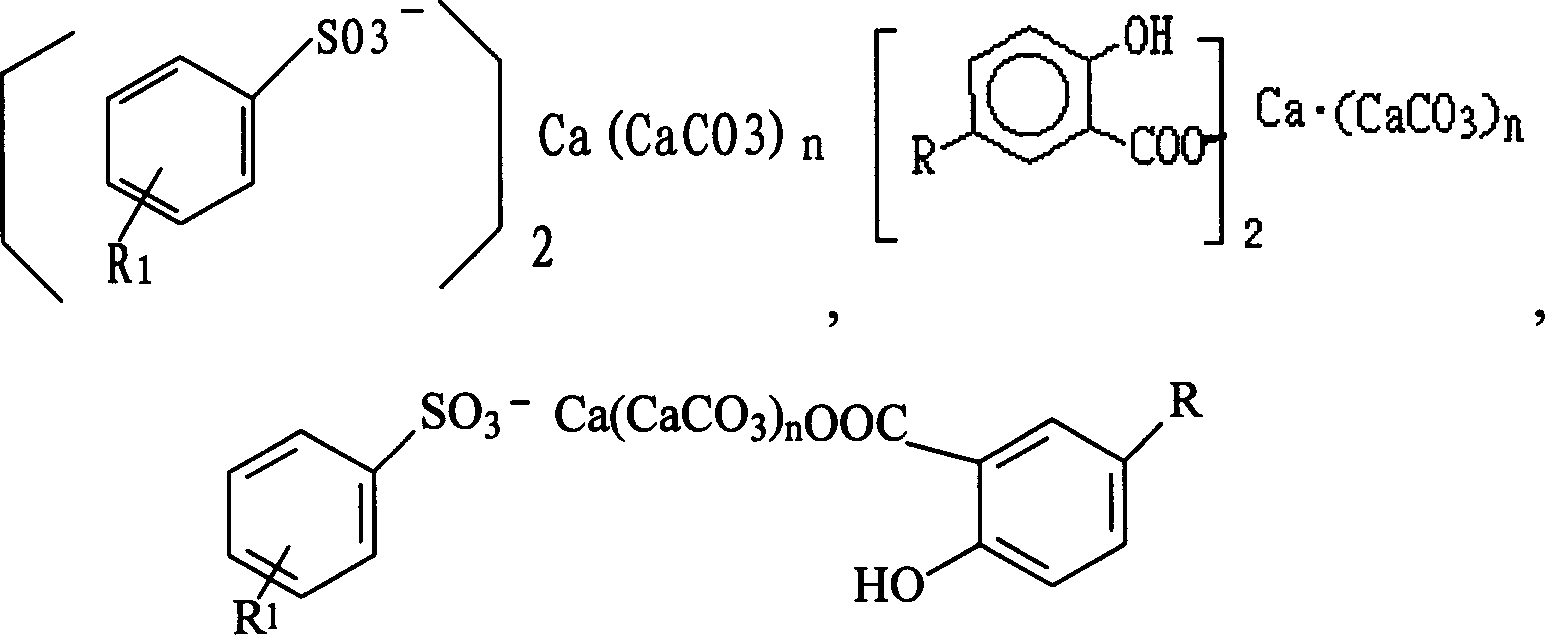

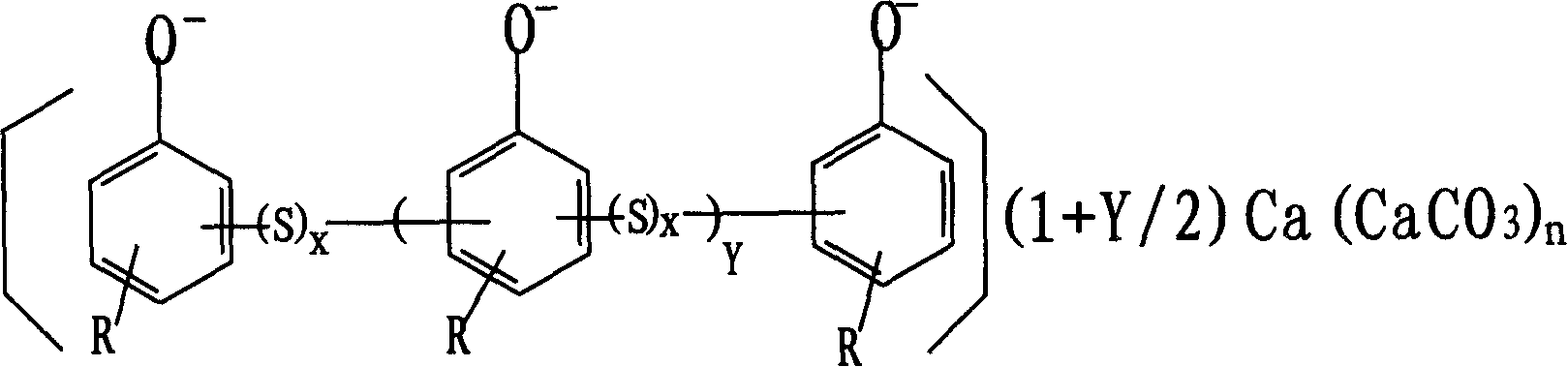

Method used

Image

Examples

Embodiment 1

[0037] Prepare a full-component 15W / 40CF diesel engine oil, which contains modified alkyl salicylate calcium, mixed matrix metal detergent (or high alkali value alkyl salicylate calcium), sulfurized alkyl phenate calcium, dienyl butyl Diimide ashless dispersant, zinc dialkyldithiophosphate. The data thus obtained are listed in Table 1.

[0038] Comparative example 1

[0039] Note: The base oil is hydrotreated base oil compounded with an appropriate amount of pour point depressant, antifoaming agent and viscosity index improver.

Embodiment 2

[0041] Prepare a full-component 15W / 40CF diesel engine oil, which contains modified alkyl calcium salicylate, mixed matrix metal detergent (high base value calcium sulfonate), sulfurized alkyl phenate calcium, and dienyl succinimide , zinc dialkyldithiophosphate and phenolic auxiliary antioxidant. The data thus obtained are listed in Table 2.

[0042] Comparative example 2

Embodiment 3

[0044]Prepare a full-component 15W / 40CF diesel engine oil, which contains modified alkyl calcium salicylate, mixed matrix metal detergent, sulfurized alkyl phenate calcium, dienyl succinimide, dialkyl dithiophosphoric acid Zinc and phenolic secondary antioxidants. The data thus obtained are listed in Table 3.

[0045] Comparative example 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com