High-base number metal detergent and preparation method thereof

A technology of metal detergent and high alkali value, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problem that the performance of detergent cannot be significantly improved, and achieve the effect of wide application and good anti-oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

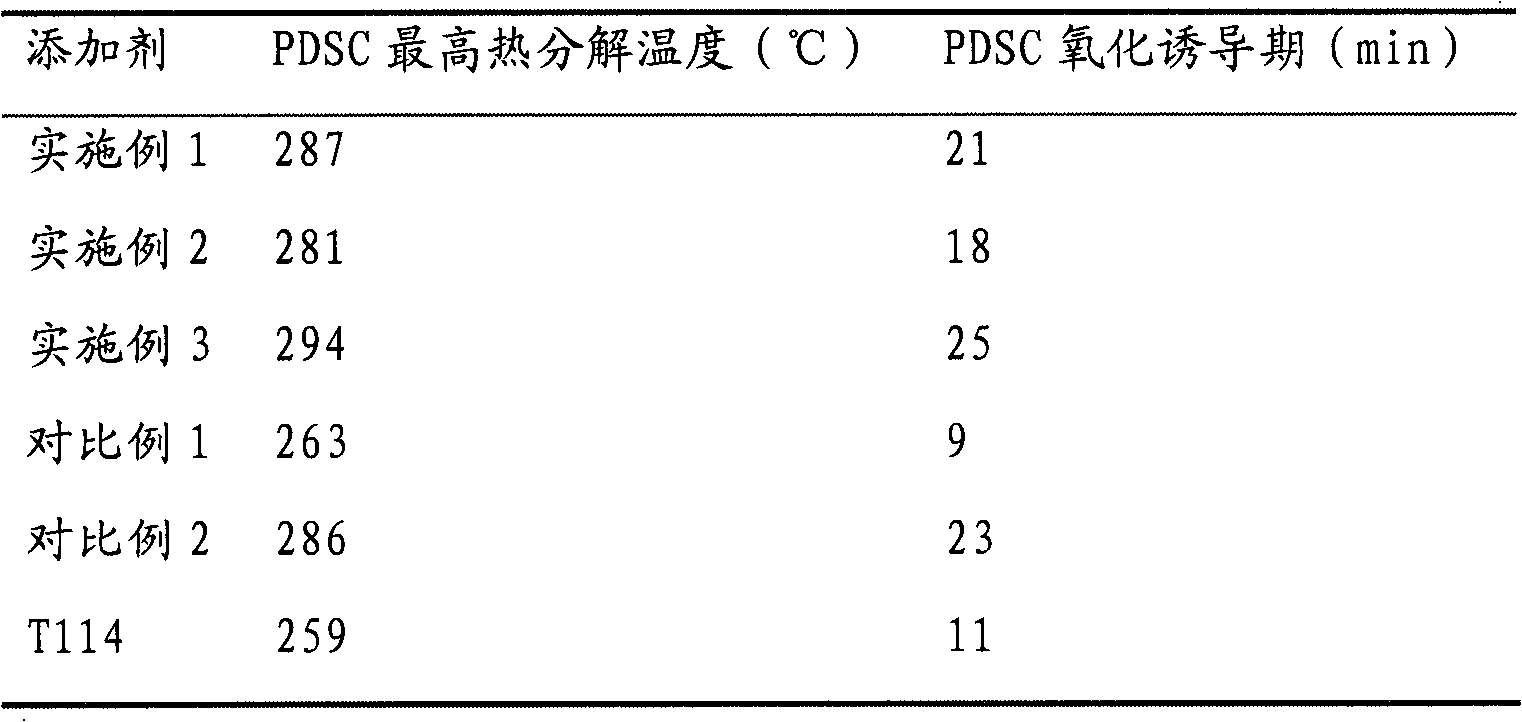

Examples

Embodiment 1

[0031] Add 150 milliliters of 120# solvent gasoline, 35 grams of 150SN neutral oil, 10 grams of 10 wt % sodium hydroxide aqueous solution, 10 grams of calcium hydroxide, and 60 grams of naphthenic acid in a 500 milliliter three-necked flask with a motor stirrer and a condenser. gram (acid value 85mgKOH / g), 14 grams of dodecylphenol (the content of p-position monosubstituted alkylphenol is 75wt%), control reaction temperature at 45~60 ℃, after neutralization reaction 60min, generate neutral ring calcium alkanoate. Add 15 grams of calcium hydroxide, 20 grams of methanol, and 20 grams of n-butanol, and pass in carbon dioxide at a ventilation rate of about 80ml / min. When the flow rate reaches 70% of the theoretical value, add 15 grams of calcium hydroxide, and pass in carbon dioxide Carry out secondary carbonation reaction, when the absorption rate of carbon dioxide reaches 80%, the reaction ends. After the carbonation is completed, the temperature is raised to 120°C to remove al...

Embodiment 2

[0033] Add 150 milliliters of 120# solvent gasoline, 35 grams of 150SN neutral oil, 10 grams of 10 wt % sodium hydroxide aqueous solution, 10 grams of calcium hydroxide, and 65 grams of naphthenic acid in a 500 milliliter three-necked flask with a motor stirrer and a condenser. gram (acid value 85mgKOH / g), 10 grams of dodecylphenol (the content of p-position monosubstituted alkylphenol is 75wt%), control reaction temperature at 45-60 ℃, after neutralization reaction 60min, generate neutral ring calcium alkanoate. Add 15 grams of calcium hydroxide, 20 grams of methanol, and 20 grams of isobutanol, and pass in carbon dioxide at a ventilation rate of about 80ml / min. When the flow rate reaches 70% of the theoretical value, add 15 grams of calcium hydroxide, and pass in carbon dioxide Carry out secondary carbonation reaction, when the absorption rate of carbon dioxide reaches 80%, the reaction ends. After the carbonation is completed, the temperature is raised to 120°C to remove a...

Embodiment 3

[0035] Add 150 milliliters of 120# solvent gasoline, 35 grams of 150SN neutral oil, 10 grams of aqueous sodium hydroxide solution of 10 wt %, 10 grams of calcium hydroxide, and 55 grams of naphthenic acid in a 500 milliliter three-necked flask with a motor stirrer and a condenser. gram (acid value 85mgKOH / g), 20 grams of dodecylphenol (the content of p-position monosubstituted alkylphenol is 75wt%), control reaction temperature at 45-60 ℃, after neutralization reaction 60min, generate neutral ring calcium alkanoate. Add 15 grams of calcium hydroxide, 20 grams of methanol, and 20 grams of isobutanol, and pass in carbon dioxide at a ventilation rate of about 80ml / min. When the flow rate reaches 70% of the theoretical value, add 15 grams of calcium hydroxide, and pass in carbon dioxide Carry out secondary carbonation reaction, when the absorption rate of carbon dioxide reaches 80%, the reaction ends. After the carbonation is completed, the temperature is raised to 120°C to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com