Cup with cover and sealing machine for cup with cover

A sealing machine and a technology with a cover, which is applied in the direction of packaging, etc., can solve the problems of unsightly appearance, inability to solve the problem of paper cover and paper cup cover not being tight, plastic cover melting, etc., and achieve the effect of reducing cost and fast and good fusion bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

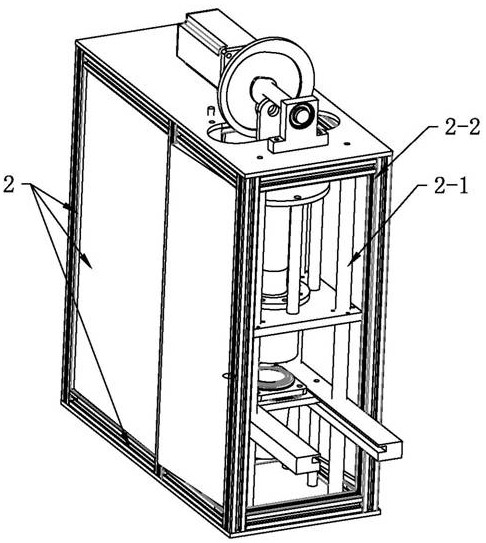

[0041] see Figures 1 to 8 The cup sealing machine with lid in this embodiment includes a support frame 2, a lower die mechanism and an upper die mechanism, the lower die mechanism and the upper die mechanism are installed on the support frame 2, and the support frame 2 includes a main frame body 2-2 and multiple A slide bar 2-1, wherein the main frame body 2-2 is assembled from a plurality of aluminum profiles.

[0042]Among them, the lower mold mechanism includes a reciprocating feeding device, a moving seat 3-1 and a lower mold 3-2. The reciprocating feeding device can drive the moving seat 3-1 to reciprocate in translation, and the lower mold 3-2 is installed on the moving seat 3-1. In the embodiment, the lower mold 3-2 is installed in the moving seat 3-1 by screws, and the lower mold 3-2 of different specifications can be replaced as required.

[0043] The reciprocating feeding device includes a guide device, a rack 3-6, a gear 3-5 and a translation drive motor 3-7. The ...

Embodiment 2

[0048] The main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the side of the cam 4-3 facing the connecting rod is provided with an annular groove track 4-13, and the side of the ejector rod facing the cam 4-3 is fixedly connected with a sliding wheel 4-14. The wheel 4-14 is located in the annular groove track 4-13, so that the sliding wheel 4-14 can always be located in the annular groove track 4-13, and the overall operation is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com