Supercritical pressure coal-fired steam-injection boiler

A steam injection boiler and supercritical technology, applied in steam boilers, steam generation, mining fluids, etc., can solve the problems of heat transfer deterioration, failure to reach supercritical pressure, poor gas injection effect, etc., to avoid heat transfer deterioration, Improve the effect of steam injection and increase the temperature of outlet steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

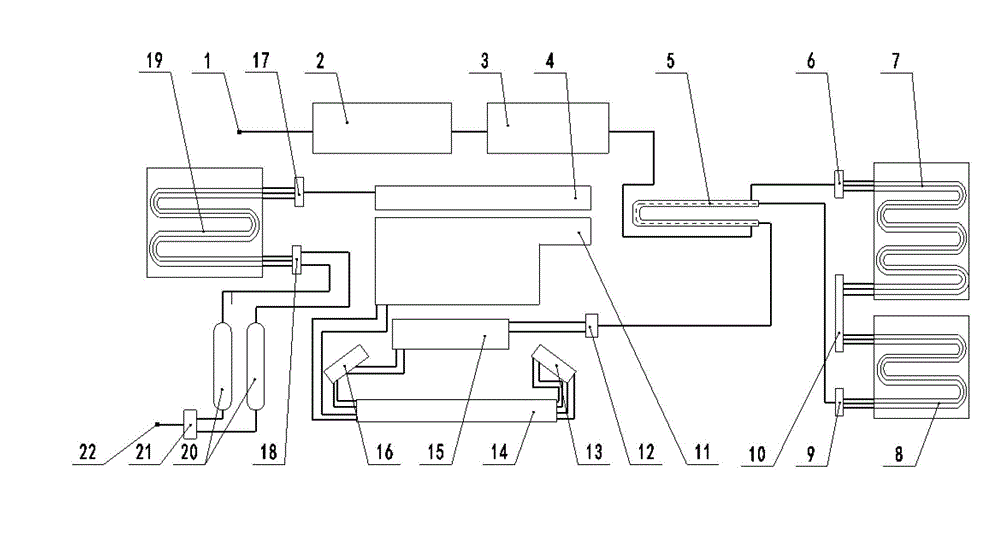

[0008] As shown in the drawings, a supercritical pressure coal-fired steam injection boiler includes a furnace, water treatment 2, plunger pump 3, feed water heat exchanger 5 and steam-water separator 20; the furnace adopts a flexible fin membrane water wall, The flexible connection of the curved heat-resistant steel plate increases the heating area of the furnace, enhances the sealing of the furnace, effectively reduces the thermal stress, and ensures the safe operation of the boiler. Tube bundles in the radiant section and 19 tube bundles in the superheating section are all made of internal threaded tubes. The water treatment 2 is connected to the plunger pump 3. The plunger pump 3 is connected to the outer pipe of the feedwater heat exchanger 5. The outer pipe of the feedwater heat exchanger 5 is connected to the header A6. , the header A6, the primary convection section 7, the header C10, the secondary convection section 8, and the header B9 are connected in sequence, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com