A flow control type impact sweating cooling head cone

A sweat cooling and nose cone technology, which is applied in the field of hypersonic aircraft structure, can solve the problems of insufficient sweat cooling capacity, etc., to prevent the deterioration of heat transfer, reduce the internal temperature, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

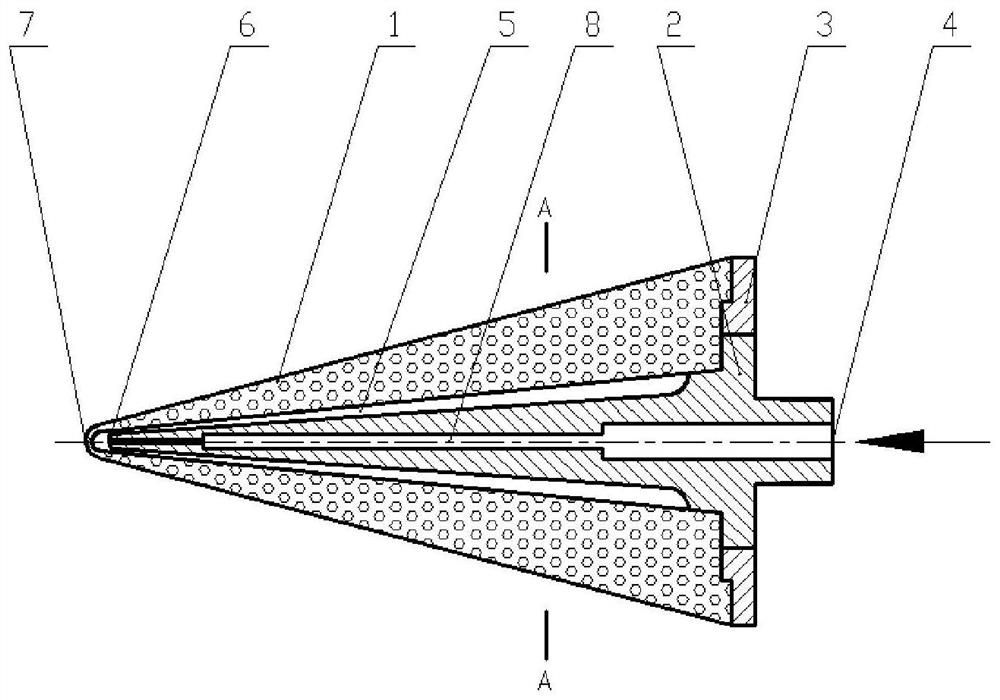

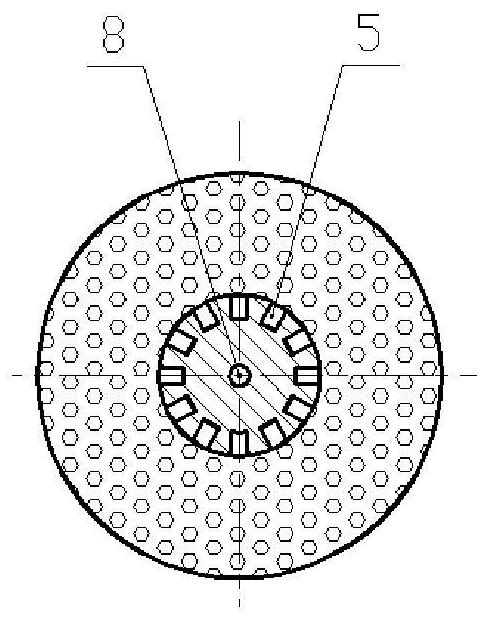

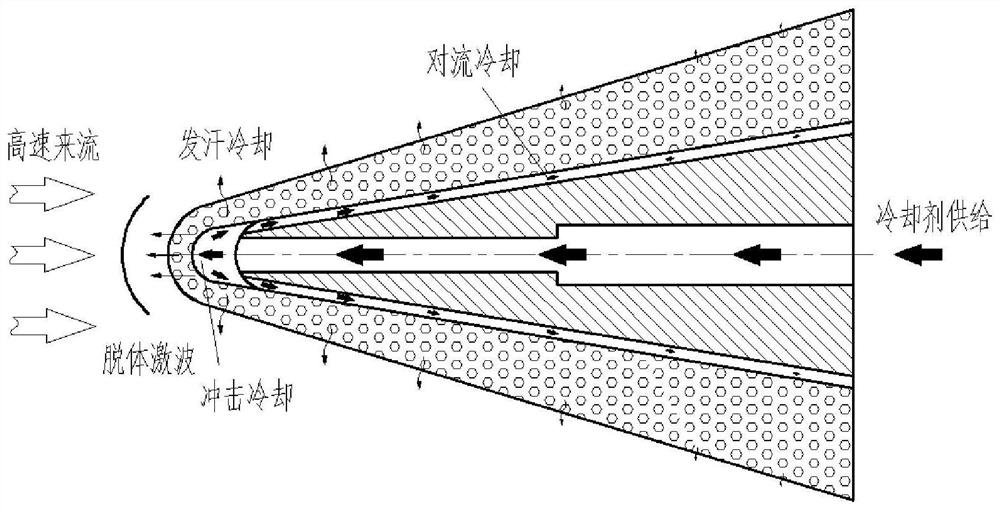

[0028] The present invention utilizes the principle of perspiration seepage cooling and impingement cooling to design a nose cone structure combining impact sweat cooling. Through this technical means, the coolant is first supplied to the highest part of the thermal environment at the front end of the nose cone, and at the same time, two methods of sweating cooling and impact cooling are used to ensure the cooling demand of the highest part of the thermal environment. And by adjusting the flow channel structure of the flow control cone core, the supply of coolant to each part of the sweating head cone can be precisely controlled, so that more coolant is supplied to the higher thermal environment of the front end of the nose cone, and the lower thermal environment of the rear end of the nose cone is cooled. Dosage supply is low. Under the premise of keeping the surface temperature of the tip lower than the ablation temperature of the outer layer material, the utilization rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com