A Feedwater Flow Control Method Adapting to Rapid Load Fluctuation

A technology of feed water flow and control method, which is applied in the field of supercritical unit feed water control, can solve problems such as large overshoot and main steam pressure fluctuations, reduce overpressure or underpressure problems, reduce lag time, and prevent heat transfer from deteriorating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

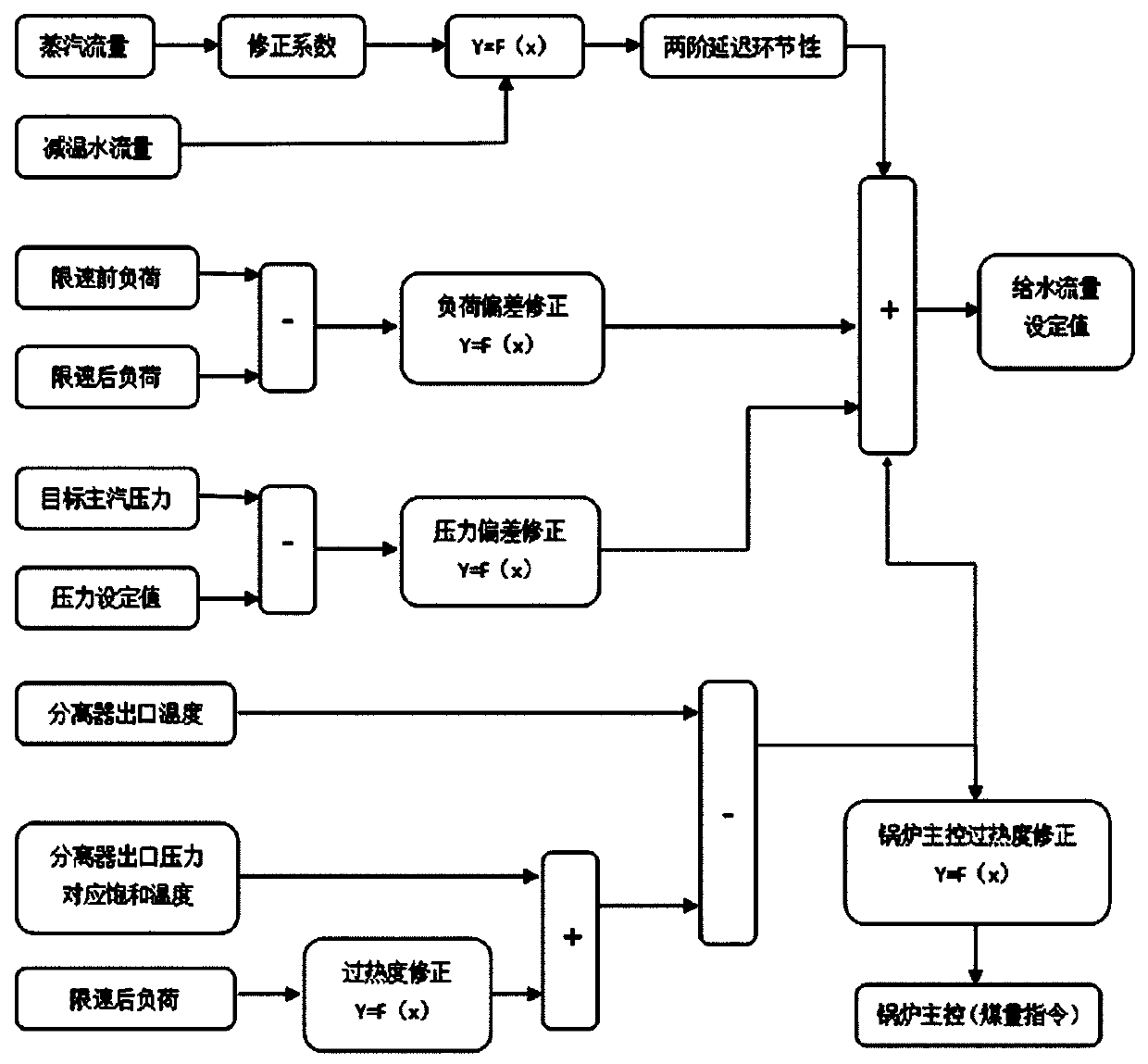

[0045] The 2X350MW supercritical circulating fluidized bed unit of a power plant in Shanxi adopts the main steam flow rate as the main input factor to ensure the rapid response of the main steam pressure. Newly added mid-point temperature deviation feed water correction and mid-point temperature boiler main control deviation, when pressure fluctuations occur , relying on the feedback adjustment of the main steam flow, when the main steam temperature deviates from the target value, relying on the intermediate temperature deviation to act on the water supply and coal flow together, the safety of the unit can be more reliably guaranteed.

[0046] Such as Figure 7As shown, the parameter record curve after adopting the water supply control strategy, in which the curve 1 is the target load command, the curve 2 is the actual power of the generator, the curve 3 is the set value of the main steam pressure, and the curve 4 is the pressure of the turbine inlet main pipe. Curve 5 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com