Film type steam generator

A steam generator and membrane technology, applied in the field of steam generation equipment, can solve the problems of high power consumption of feed water pumps, slow load response, waste of energy when starting and stopping, etc., and achieve the heating target with less water, fast response to strain, and large vaporization capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

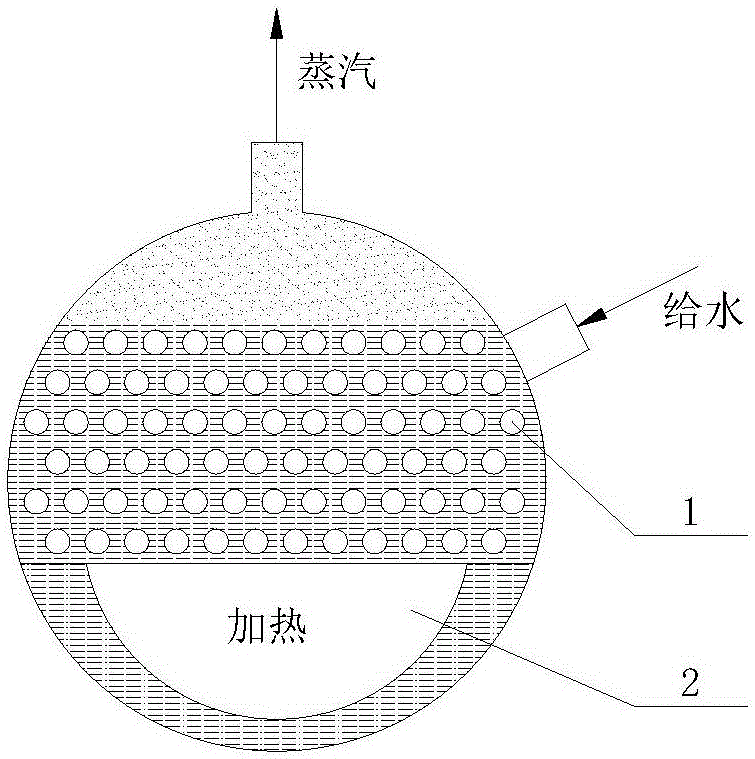

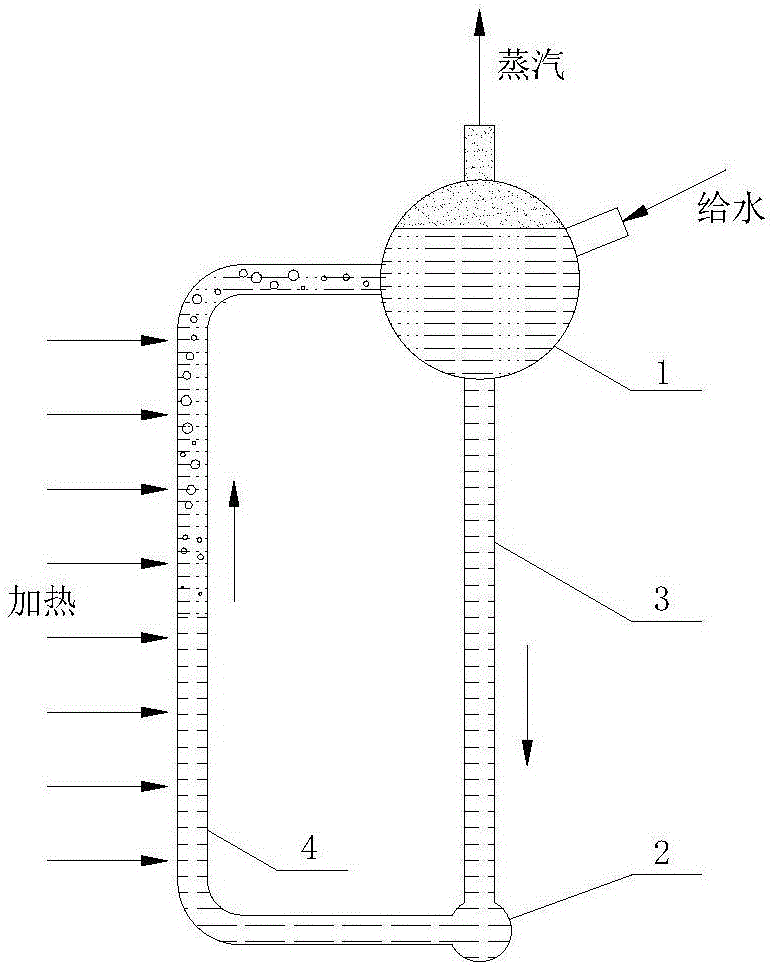

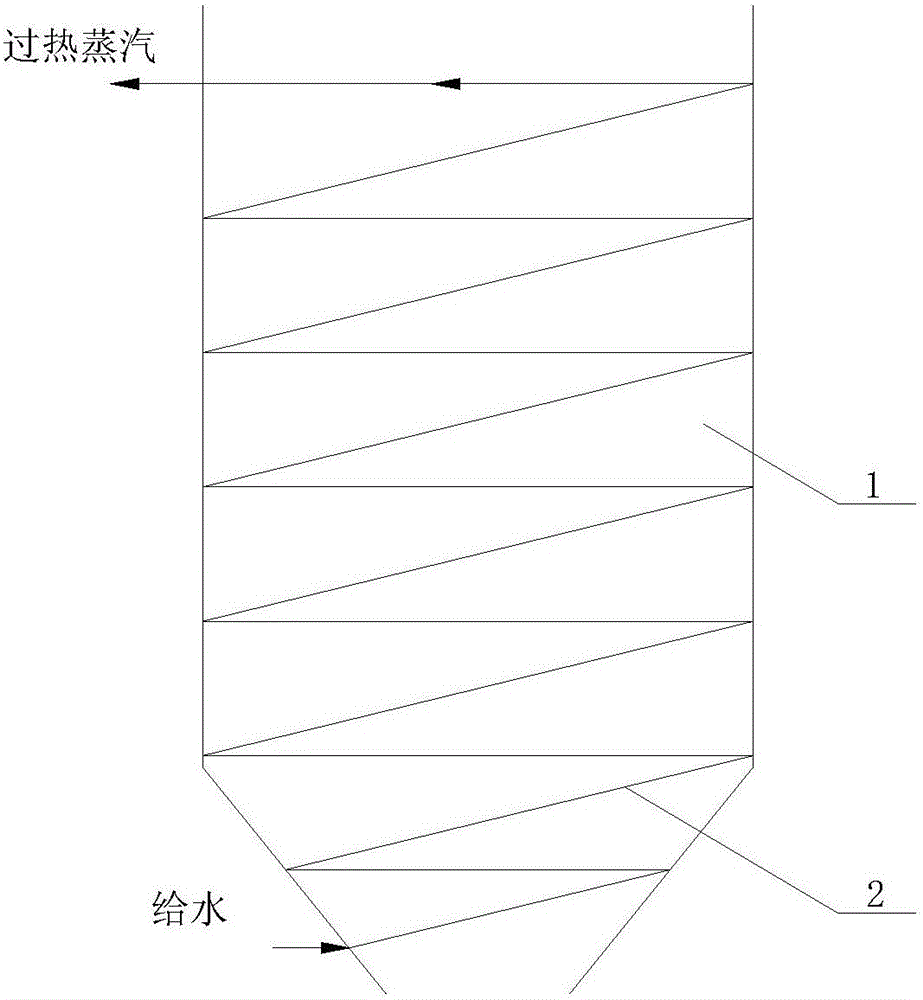

[0084] like figure 1As shown, the membrane steam generator in this embodiment is mainly composed of a water supply pipeline, a membrane evaporation tube 3, and a steam outlet and return water pipeline. The water supply pipeline includes a water supply main pipe 1 and a water supply branch pipe 2. Flow to the end of the water supply branch pipe 2, and keep flowing in one direction without dead ends. The steam outlet and return water pipeline includes a steam outlet and return water main pipe 5 and a steam outlet and water return branch pipe 4 . One end of the film evaporator tube 3 is connected to the main water supply pipe 1 and the water supply branch pipe 2, and the other end is connected to the steam outlet and return water main pipe 5 and the steam outlet and return water branch pipe 4, and the water supply is distributed to the membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com