Novel series of hydrogen peroxide thrust chambers used for rockets and airships

A technology of hydrogen peroxide and thrust chamber, which is applied in rocket engine devices, jet propulsion devices, machines/engines, etc., and can solve problems such as unsuitable thrust chamber structural strength and low engine specific impulse value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

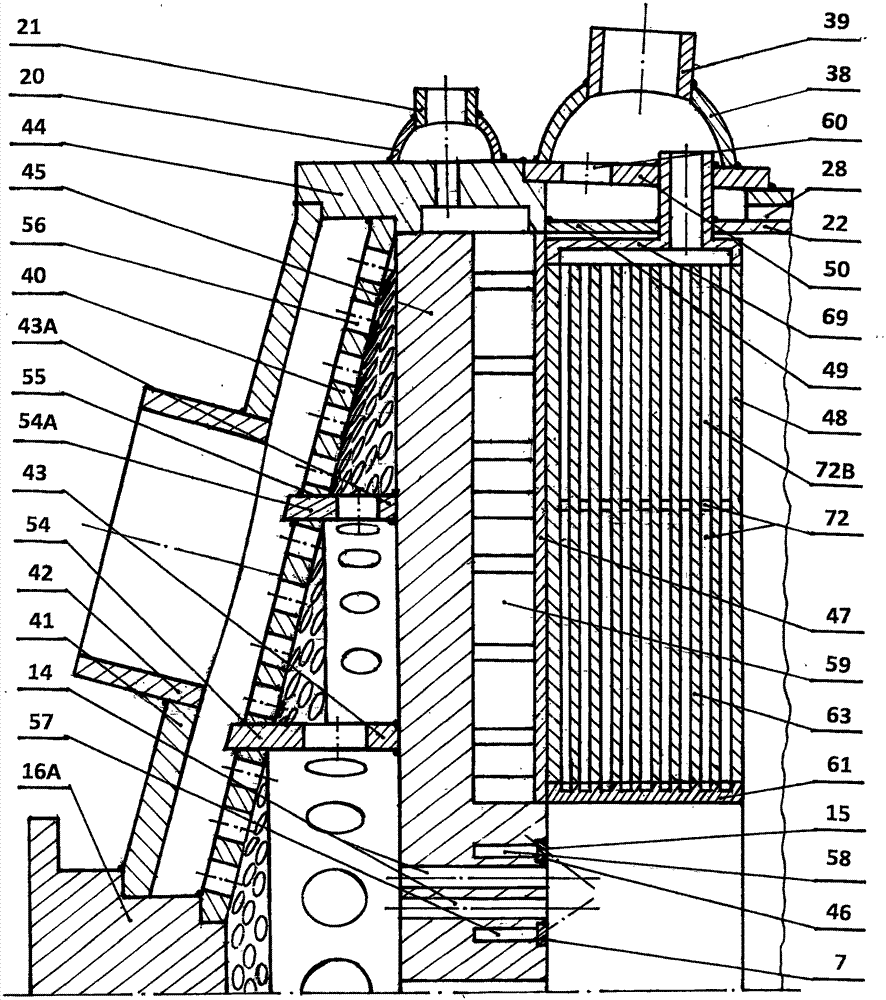

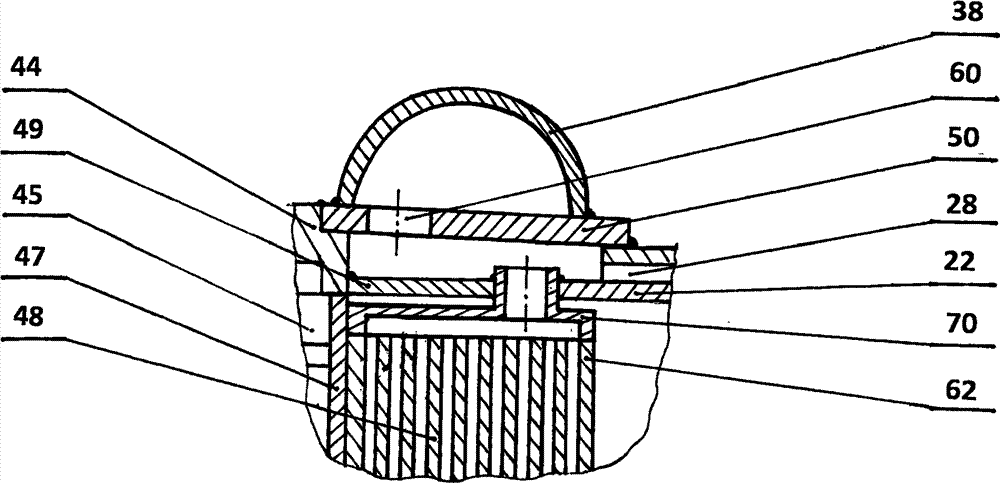

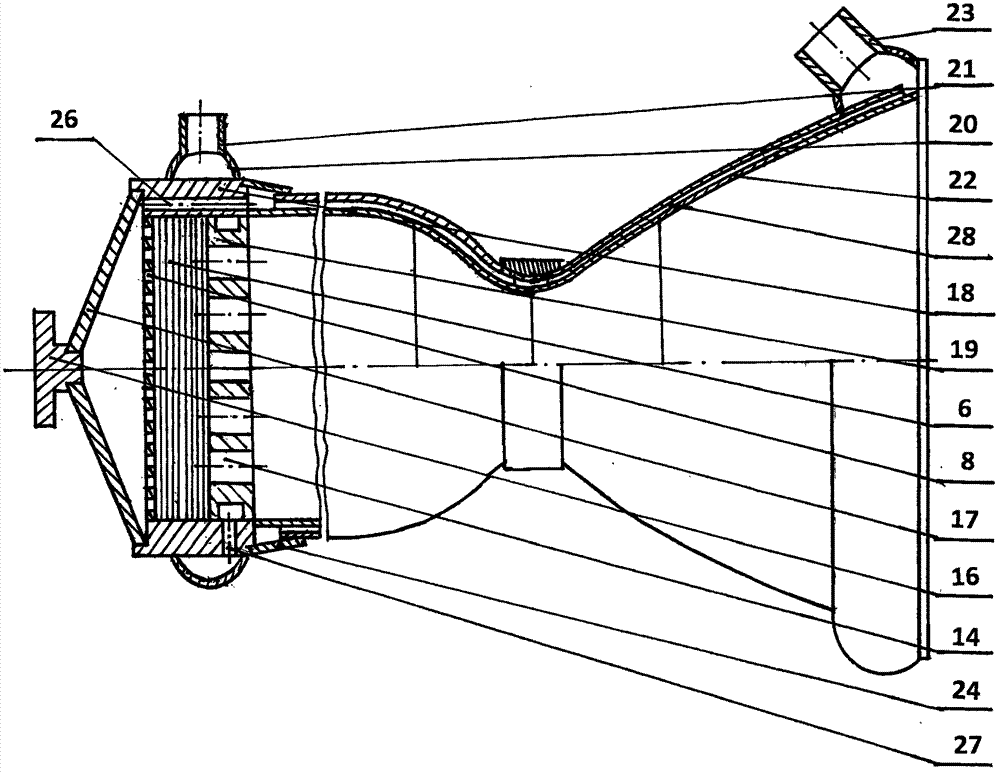

[0057] Figure 1 to Figure 9 It is a preferred embodiment of the series hydrogen peroxide thrust chambers for novel rockets and spaceships of the present invention.

[0058] Such as figure 1 As shown, a hydrogen peroxide / NHMF attitude control micro-thrust chamber consists of a top cover 1, a head shell 2 or a head shell A2A, a single-wall body 3, an oxidant solenoid valve 4, a fuel solenoid valve 5, a catalyst bed 6, and a fuel Injection ring 7, equalizer plate 8, flange plate 9, bolt 10, nut 11, gasket 12 and sealing gasket 13 are composed, screwed and welded into one. Catalyst bed 6 controls the decomposition rate of industrial grade 79.1% to 84.9% hydrogen peroxide at 75% to 95% by changing the number of silver mesh layers and flow strength, and the head shell 2 is opened with 2 to 4 oxygen-enriched The axial hole 14 or the head shell A 2A has an oxygen-enriched axial hole 14 in the center, and the head shell A 2A also has a fuel inclined hole 15 or the fuel injection rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com