Air conditioner for regenerative cooling circulation system

A technology of circulation system and air conditioner, applied in irreversible circulation compressors, superheaters, refrigerators, etc., can solve the problems of air heating, increase of outdoor unit volume, compressor liquid hammer, etc., to reduce volume and improve Energy efficiency ratio, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

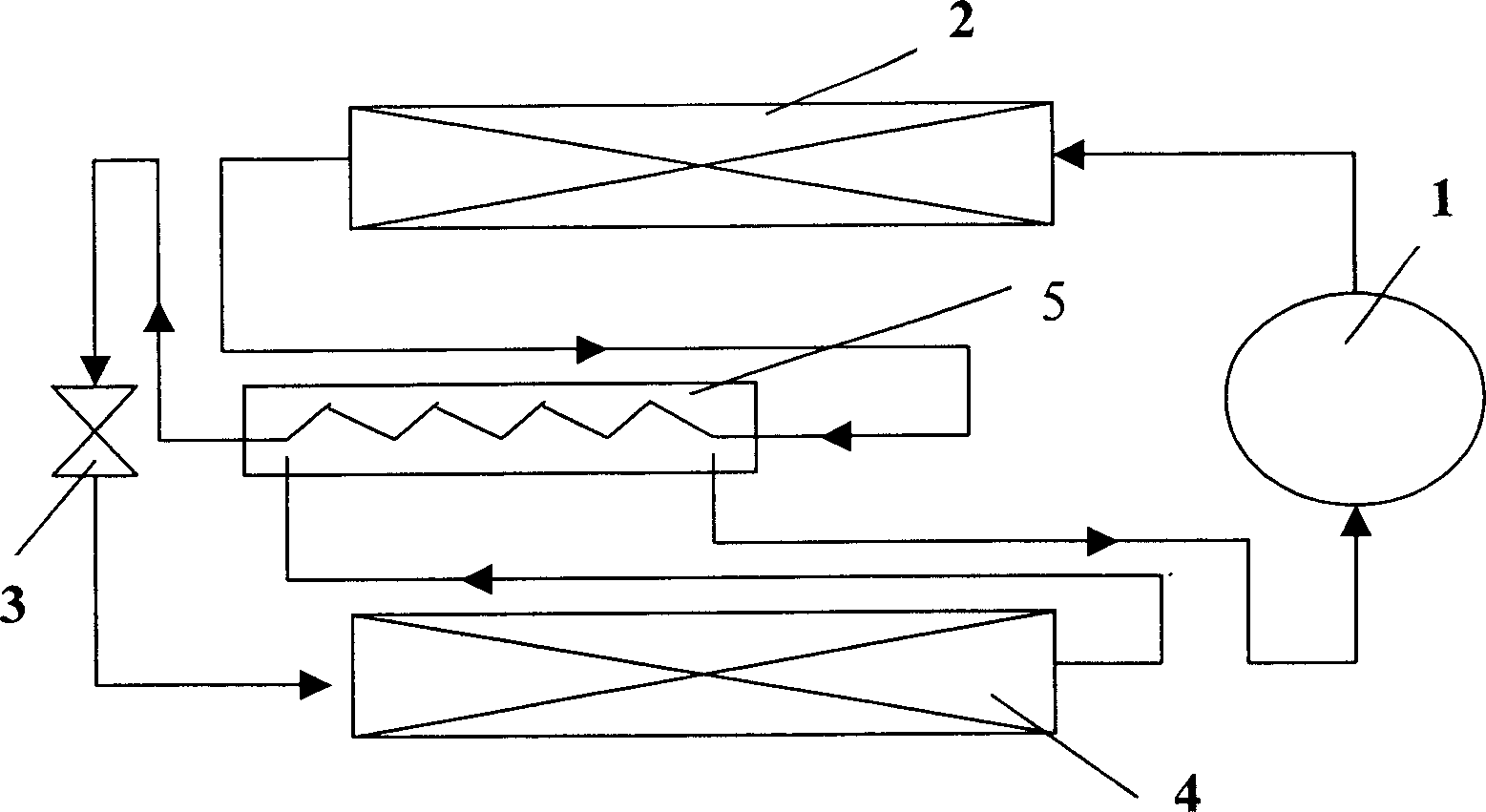

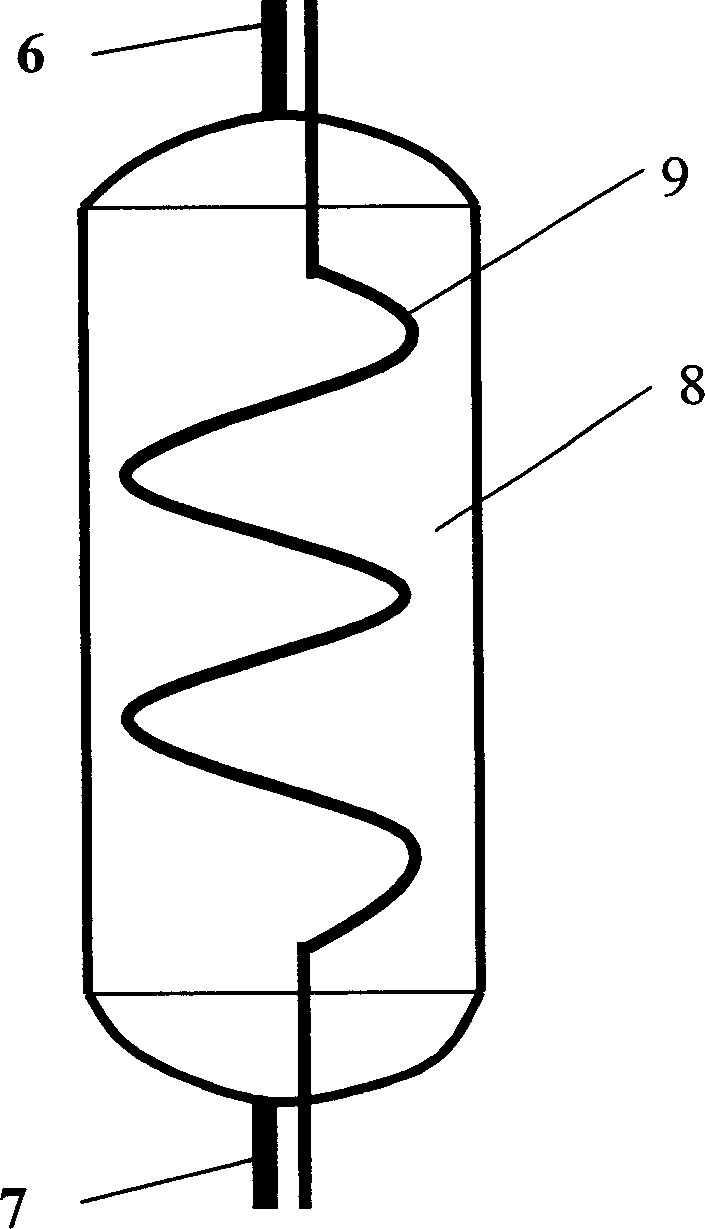

[0011] Such as Figure 1 to Figure 2 As shown, the regenerative refrigeration cycle system air conditioner provided by the present invention includes a compressor 1, a condenser 2, a throttling device 3 and an evaporator 4, and the regenerative refrigeration cycle system air conditioner also includes a heat recovery exchange device 5. The heat recovery exchanger 5 includes a top and a bottom respectively provided with a low-pressure refrigerant outlet 6 connected to the outlet of the compressor 1 and the outlet of the evaporator 4, a cylindrical tank 8 with an inlet 7 and a cylindrical tank 8 arranged in the vertical direction. Inside the tank body 8, the upper and lower ends are straight pipes respectively connected to the outlet of the condenser 2 and the throttling device 3, and the middle is a spiral heat exchange coil 9 integrally formed with the straight pipe. The heat exchange coil 9 is a built-in screw type or an external fin type, which can improve heat exchange effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com