Subsonic velocity combustion ramjet combustion chamber and regenerative cooling method thereof

A ramjet, regenerative cooling technology, applied in ramjet engines, mechanical equipment, etc., can solve problems such as difficulty in cooling, achieve sufficient combustion, high combustion efficiency, expand the applicable flight Mach number and effectively stabilize the working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other arbitrarily if there is no conflict.

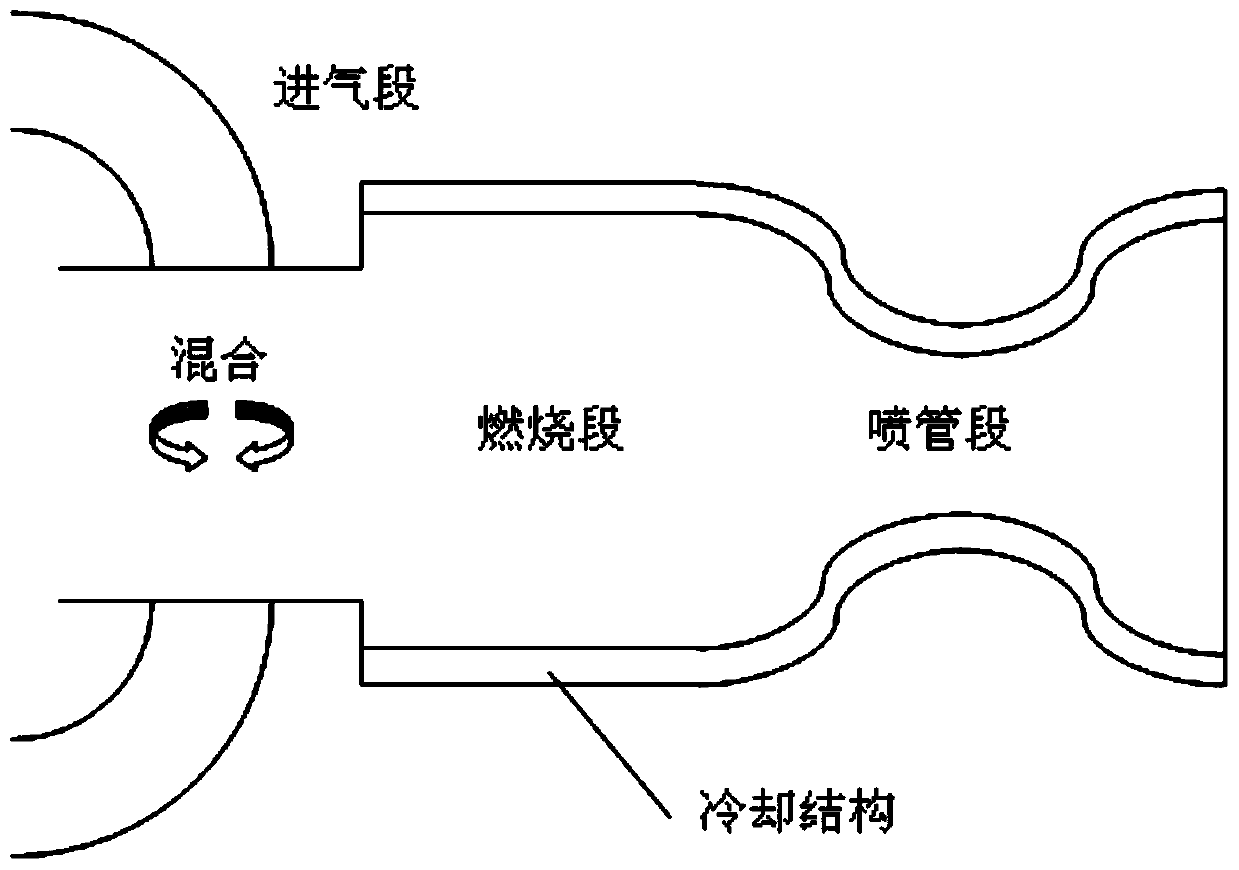

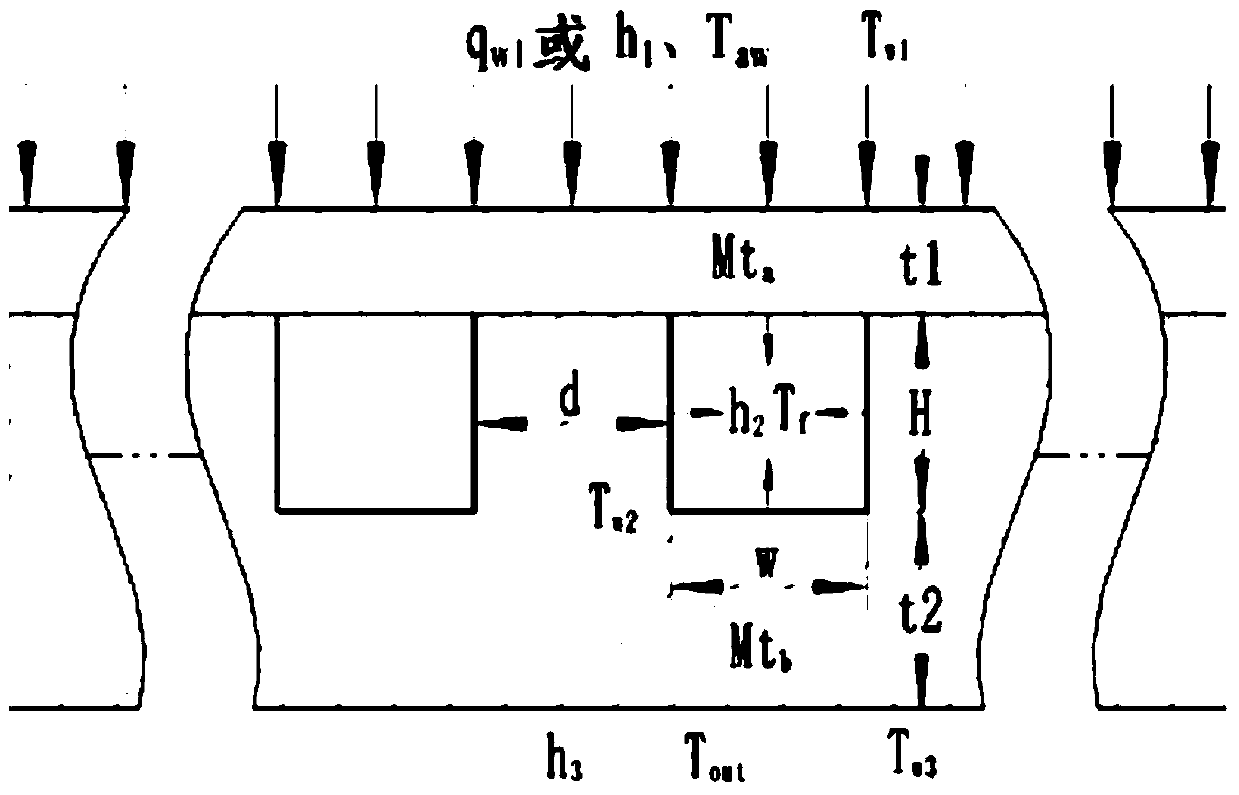

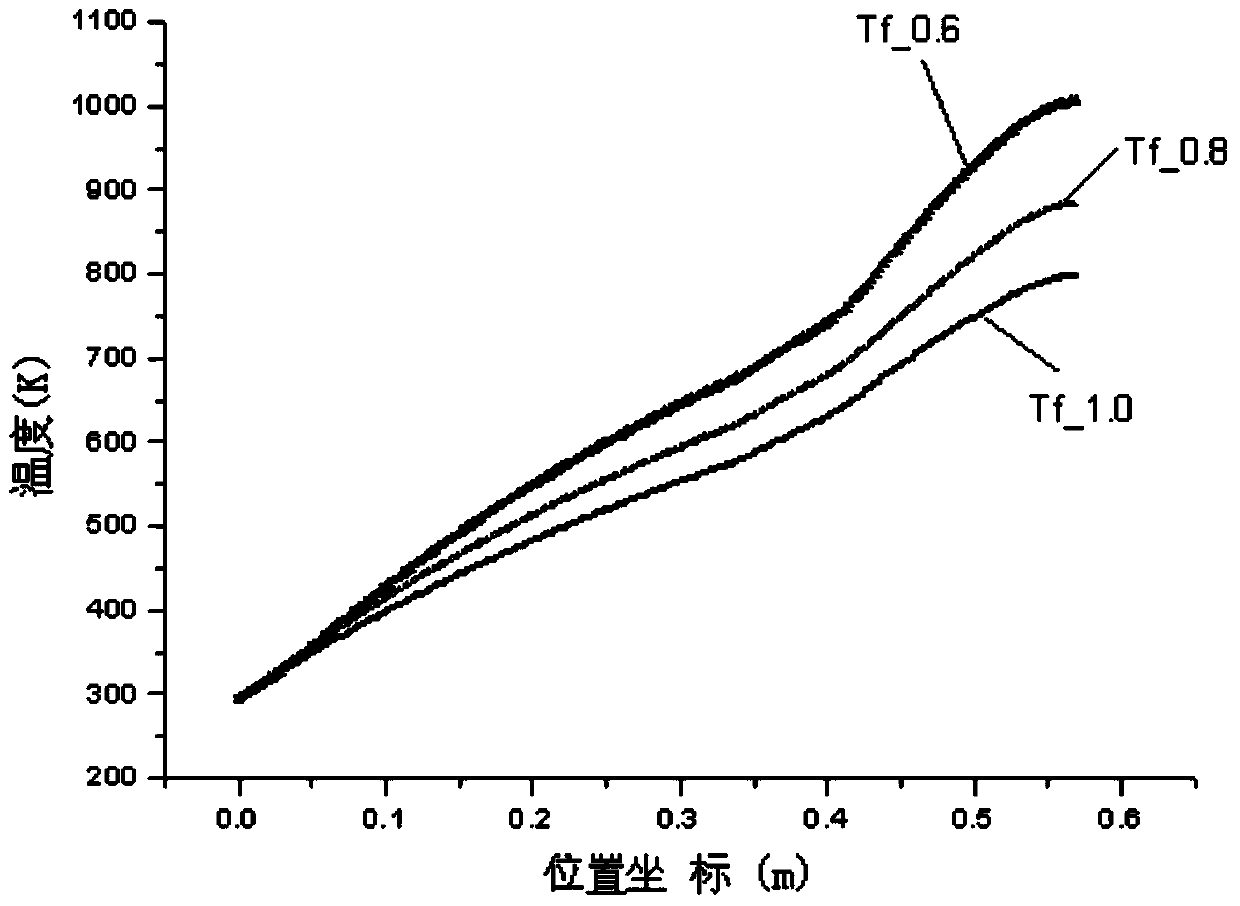

[0027] The invention proposes a subsonic combustion ramjet combustion chamber with a regenerative cooling structure, and a method for regeneratively active cooling of the subsonic combustion ramjet combustion chamber using airborne hydrocarbon fuel. Through preliminary tests on a set of quantitatively designed cooling structure engine combustion chambers, the feasibility of this cooling method is preliminarily verified. In a nutshell, the cooling method is a method of injecting the engine's hydrocarbon fuel into the combustion chamber to generate thrust before it flows through the cooling structure covering the surface of the engine's combustion chamber for efficient thermal protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com