Combined type scramjet engine cooling circulation system

A technology of engine cooling and scramjet, which is applied in the direction of engine cooling, engine components, turbine/propulsion device cooling, etc., can solve the problems of scramjet regenerative cooling difficulties, excessive cracking and coking of cooling fuel, etc., to avoid transmission Heat worsens extreme working conditions, weakens the wall temperature, and avoids the effect of blocking the cooling channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

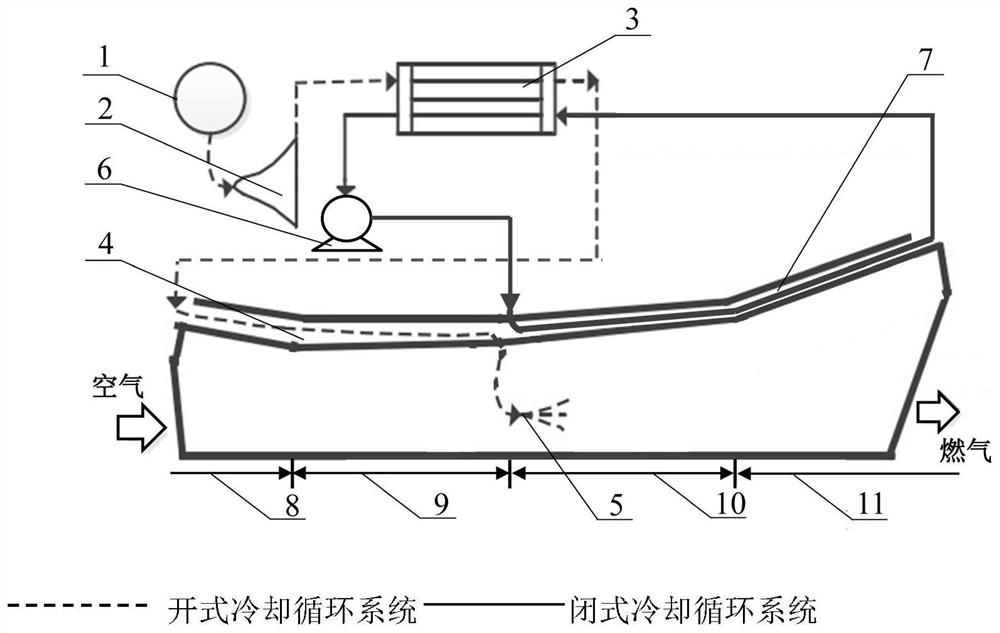

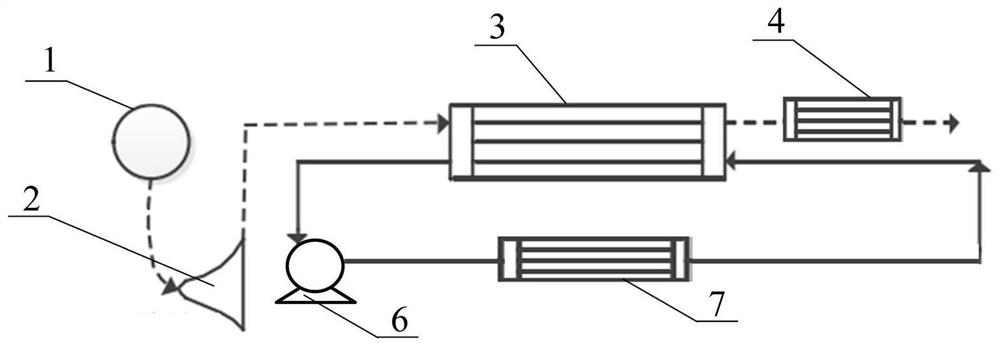

[0020] refer to figure 1 Said, a combined scramjet cooling cycle system of the present invention comprises an open cooling cycle system and a closed cooling cycle system; the working fluid in the open cooling cycle system is kerosene; the closed cooling cycle The working medium in the system is liquid metal, and the liquid metal is one or more combinations of lead, sodium, lithium, cesium, rubidium, sodium-potassium alloy, lead-bismuth alloy, lithium-lead alloy and doped indium alloy.

[0021] The open cooling circulation system is actually the fuel flow cooling side, including fuel tank 1, fuel pump 2, heat exchanger 3, first cooling passage 4, fuel injector 5, and all components are connected by pipelines . The fuel tank 1 is connected to the inlet of the fuel pump 2, the heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com