Pre-opening roller structure of waste fiber leftover pre-opener

A pre-opening machine and pre-opening technology, which is applied in the direction of fiber opening and cleaning machines, etc., can solve the problems of atmospheric environment impact, short service life of card clothing, and increased cost of automotive interior parts, so as to achieve long service life and ensure use The effect of life, good opening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

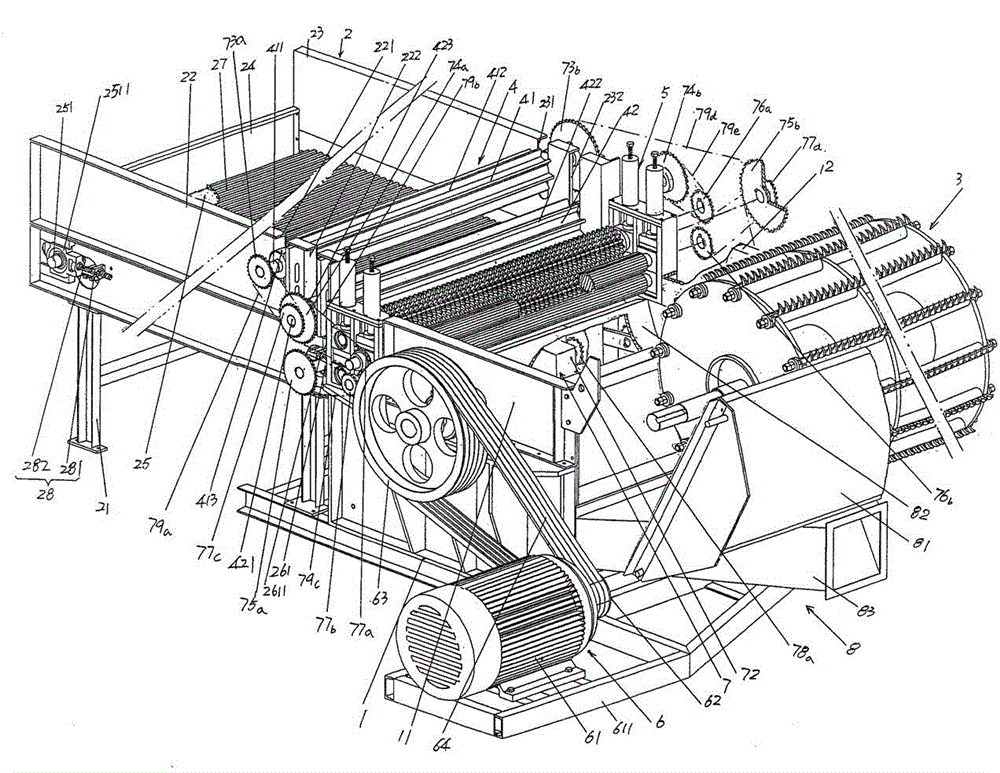

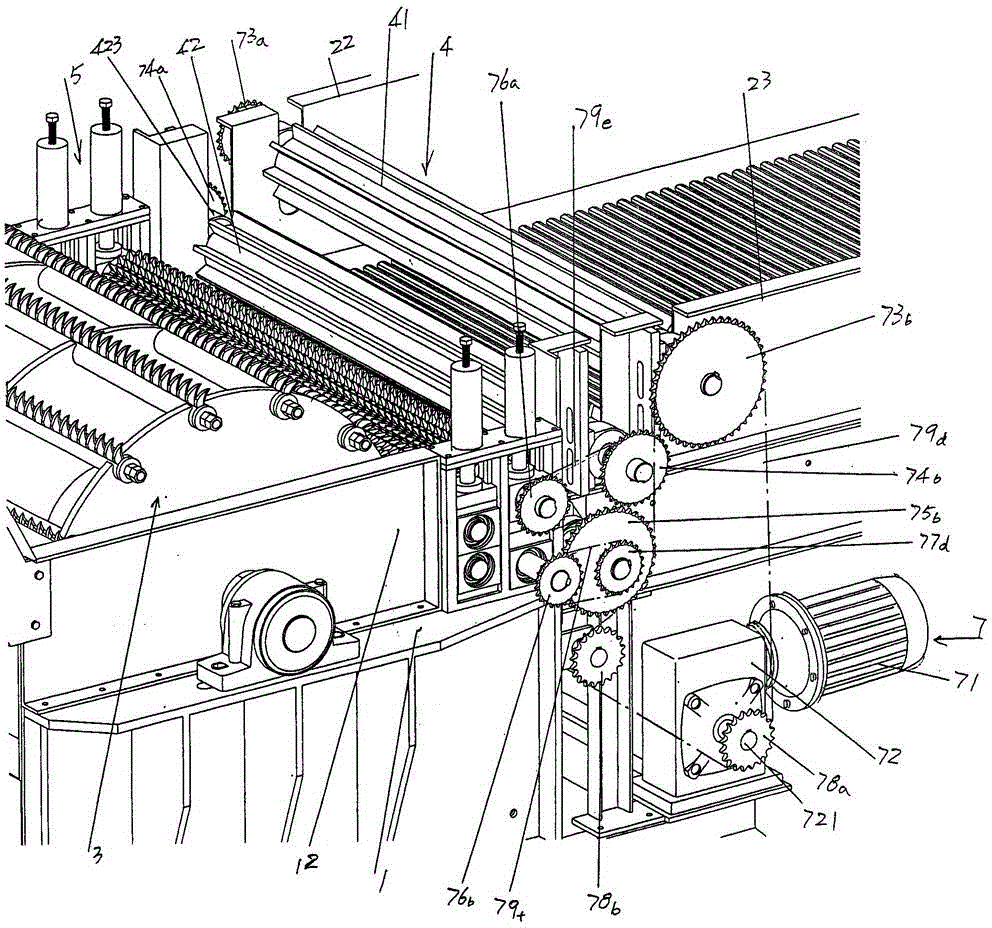

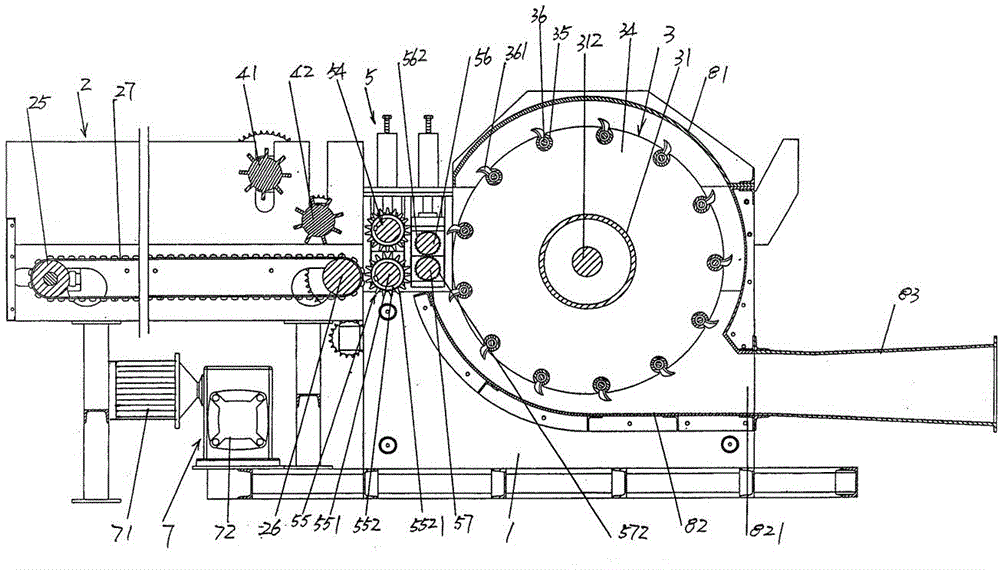

[0017] See figure 1 , a pre-opening roller frame 1 belonging to the structural system of the waste fiber scrap opening machine is provided, and one side of the length direction of the pre-opening roller frame 1 is figure 1 A first wallboard 11 is fixed above the front side of the shown position state, and a second wallboard 12 is fixed at the rear side, and the positions of the first and second wallboards 11 and 12 correspond to each other.

[0018] The given waste fiber and leftover conveying mechanism 2 is connected to one end of the aforementioned pre-opening roller frame 1, that is, connected to figure 1 The left end of the position state shown in , the preferred but not absolutely limited structure of the waste fiber and scrap conveying mechanism 2 is as follows: comprising conveying support 21, first and second support wallboards 22, 23, side baffles 24, first, The second delivery curtain roller 25,26, delivery curtain 27 and a pair of delivery curtain tension adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com