Method for separating desulfurization waste water by using electric drive membrane

A desulfurization wastewater and electric-driven membrane technology, applied in the field of desulfurization, can solve the problems of strong corrosion, and achieve the effects of enhanced residual chlorine resistance, convenient desalination of high-salt water and concentration of wastewater, and good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

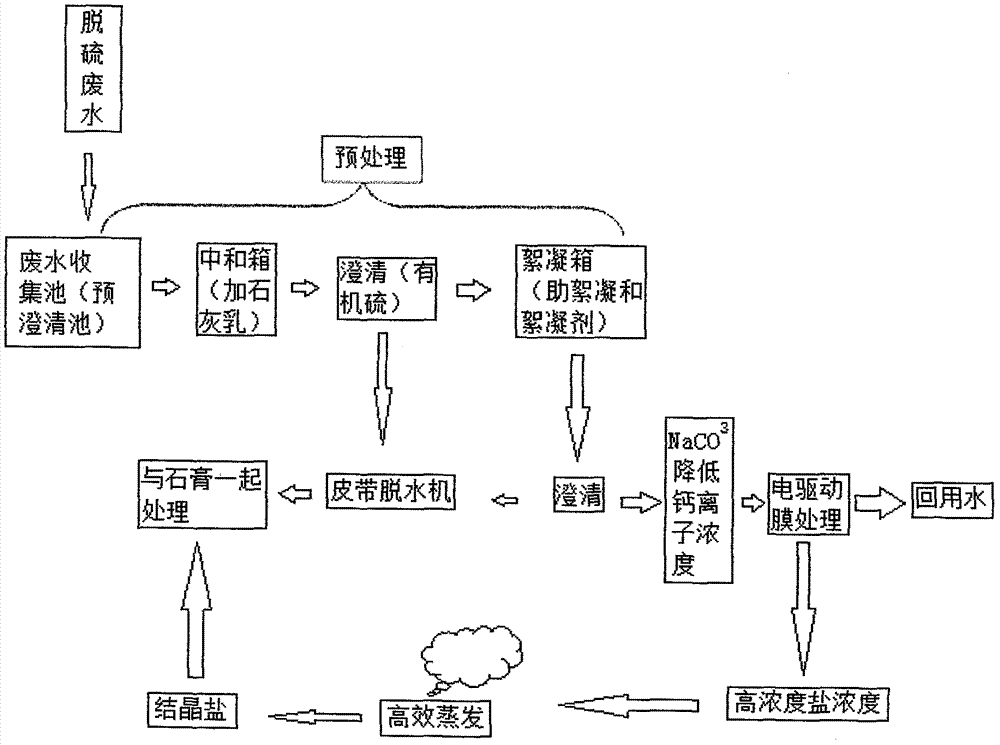

[0038] A method for separating desulfurization wastewater by using an electrically driven membrane, the method is as follows

[0039] Step A) front-end pretreatment: first collect the desulfurization wastewater into the collection tank for preliminary precipitation; then enter the triple tank; the triple tank is a neutralization tank, a settling tank and a flocculation tank; In the neutralization tank, 5% milk of lime solution is added to the neutralization tank to form a precipitate, and about 5% milk of lime solution is added to the neutralization tank to increase the pH value of the wastewater to above 9.0. In this environment, most heavy metal ions will Insoluble hydroxides formed and precipitated. After the reaction, the desulfurization wastewater enters the settling tank, and organic sulfide (sodium sulfide) is added to the settling tank to form a precipitate again, and the heavy metal ions form insoluble hydroxides. At the same time, the Ca in the milk of lime 2+ with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com