Treatment technology and equipment for recycling wastewater of surfactant industry

A technology for surfactants and industrial wastewater, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as degradation activity limitation, achieve cost control, reduce personnel burden, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

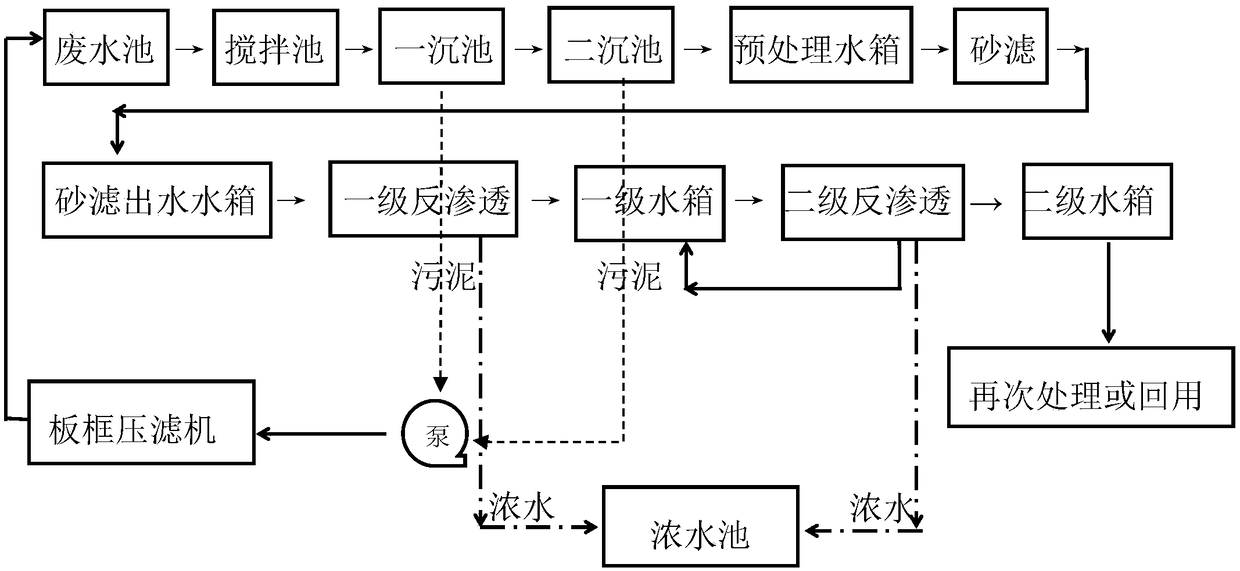

[0050] Such as figure 1 As shown, the treatment equipment for wastewater reuse in the surfactant industry in this embodiment is sequentially arranged along the direction of waste water flow, waste water tank, stirring tank, primary sedimentation tank, secondary sedimentation tank, pretreatment water tank, sand filter equipment, Sand filter water tank, primary reverse osmosis system, primary water tank, secondary reverse osmosis system, secondary water tank;

[0051]Among them, between the stirring tank and the first settling tank, the first settling tank and the second settling tank, the waste water enters the follow-up equipment through the overflow pipe according to the height difference; the second settling tank also passes through the pipeline and the waste water tank or the stirring tank Connected;

[0052] After the wastewater enters the mixing tank, the dosing box adds PAC, PAM, and pH regulators according to the wastewater conditions, and after full stirring, it over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com