Treatment system for chromium-containing dyeing wastewater and implementation method thereof

A dyeing wastewater and treatment system technology, applied in the field of chromium-containing dyeing wastewater treatment system, can solve the problems of secondary pollution, complex operation and management, large amount of sludge, etc., and achieve strong impact load resistance, high system stability, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

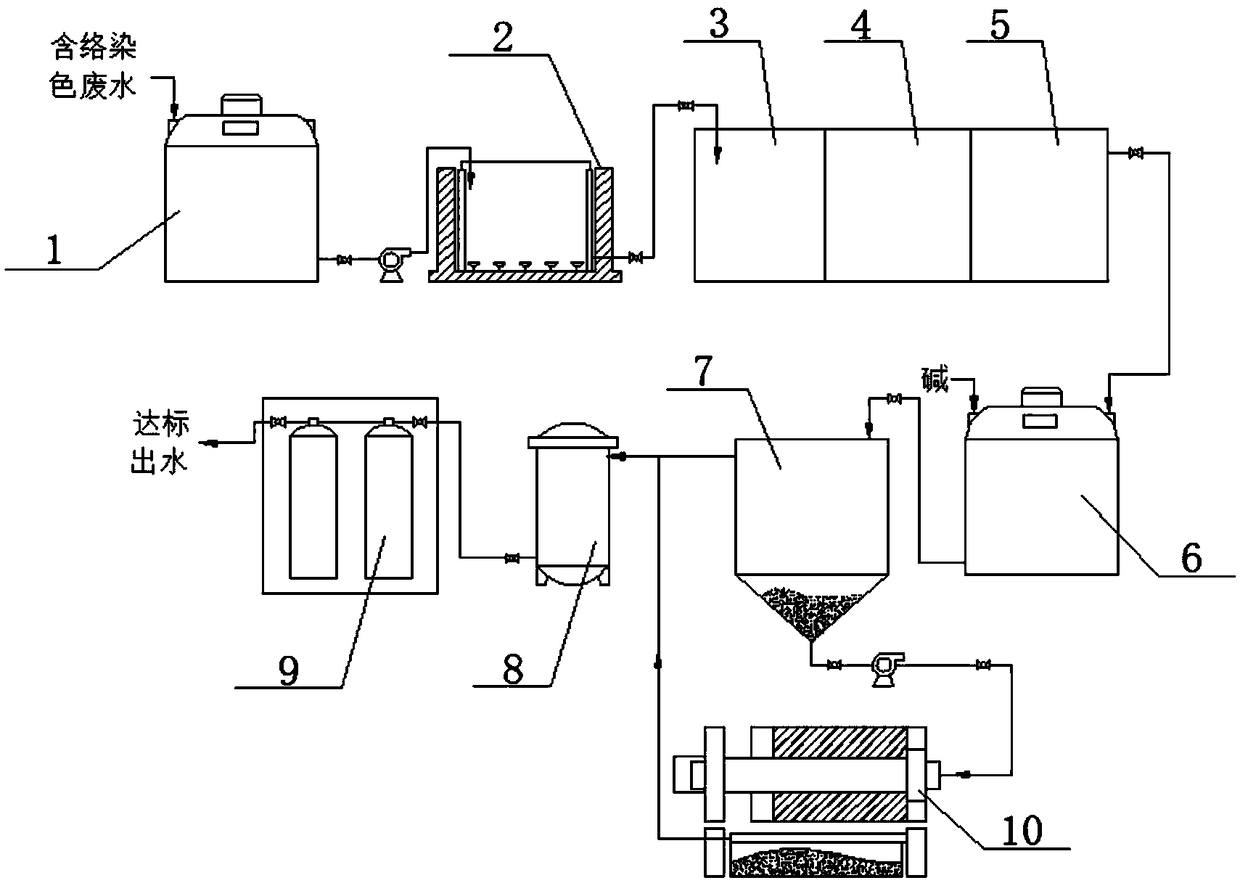

[0027] A treatment system for chromium-containing dyeing wastewater, including wastewater collection barrel 1, three-dimensional electrolysis reaction tank 2, 1#Ph adjustment tank 3, advanced oxidation decolorization tank 4, reduction tank 5, 2#Ph adjustment tank 6, 2#Ph adjustment Pool 6, filter 8, ion adsorption device 9 and mud press 10, the outlet of waste water collection bucket 1 is connected with three-dimensional electrolysis reaction tank 2, the outlet of three-dimensional electrolysis reaction tank 2 and the water inlet of 1#Ph regulating tank 3 Connection, the outlet of 1#Ph regulating tank 3 is connected with the inlet of advanced oxidation decolorization tank 4, the outlet of advanced oxidation decolorization tank 4 is connected with reduction tank 5, and the outlet of reduction tank 5 is connected with that of 2#Ph regulating tank 6. Water inlet connection, the water outlet of 2#Ph regulating pool 6 is connected with the water inlet of 2#Ph regulating pool 6, the w...

Embodiment 2

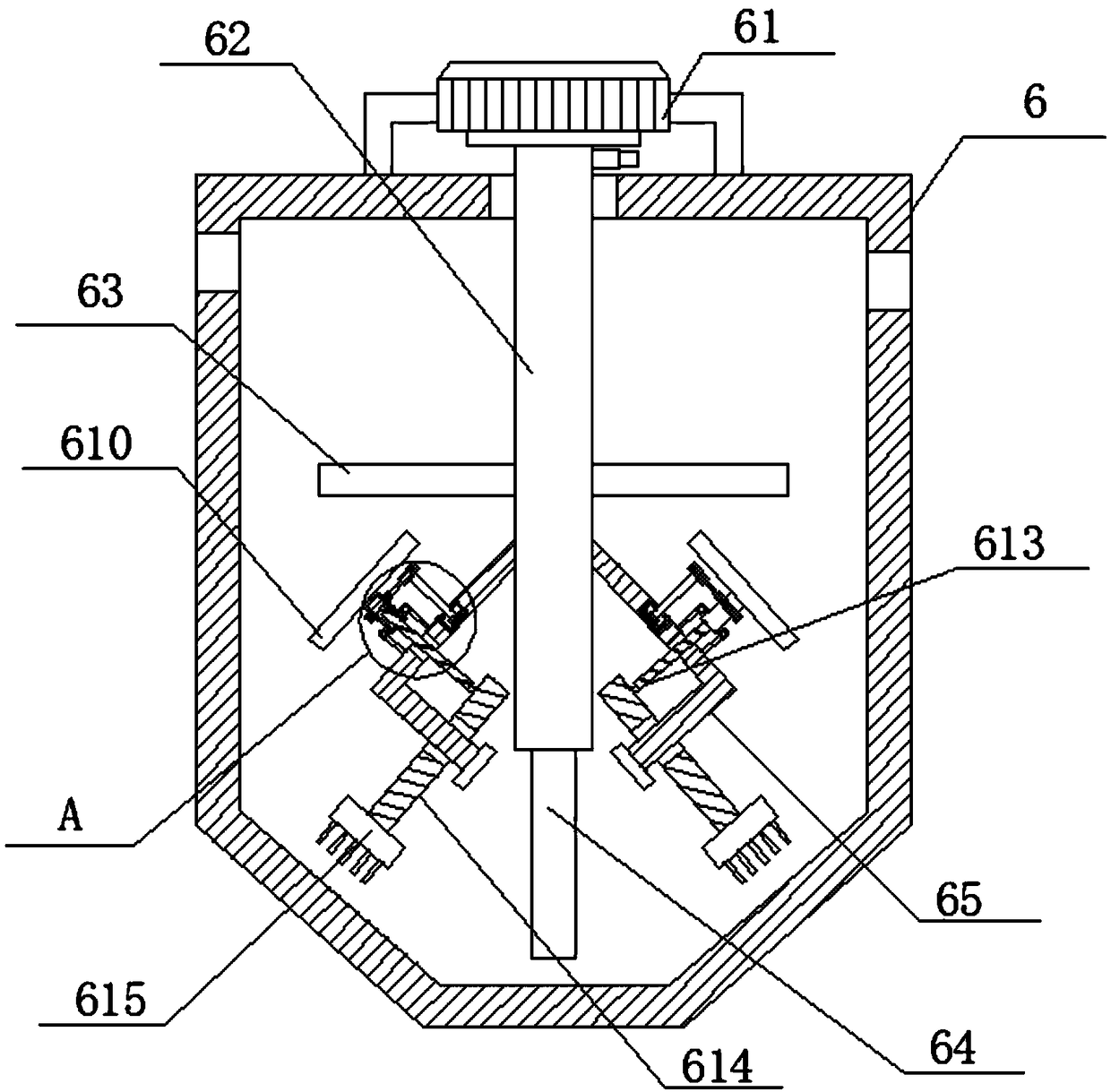

[0029] 2#Ph regulating tank 6 is equipped with a stirring device, 2#Ph regulating tank 6 is provided with a water inlet at the upper end of the side wall, 2#Ph regulating tank 6 is provided with a water outlet at the upper end of the side wall away from the water inlet, 2#Ph regulating tank The bottom end of 6 is provided with a discharge port. The stirring device includes a rotating motor 61 and a stirring shaft 62. The side wall of the rotating motor 61 is fixedly connected with the outer top wall of the 2#Ph regulating tank 6 through a support frame. The rotation on the rotating motor 61 The shaft is fixedly connected to one end of the stirring shaft 62, and the other end of the stirring shaft 62 rotates through the top of the 2#Ph regulating tank 6 to reach the inside of the 2#Ph regulating tank 6 and is fixedly connected with the vertical stirring blade 64. The stirring shaft 62 is located at 2 The side wall of a section of #Ph regulating pool 6 is symmetrically connected w...

Embodiment 3

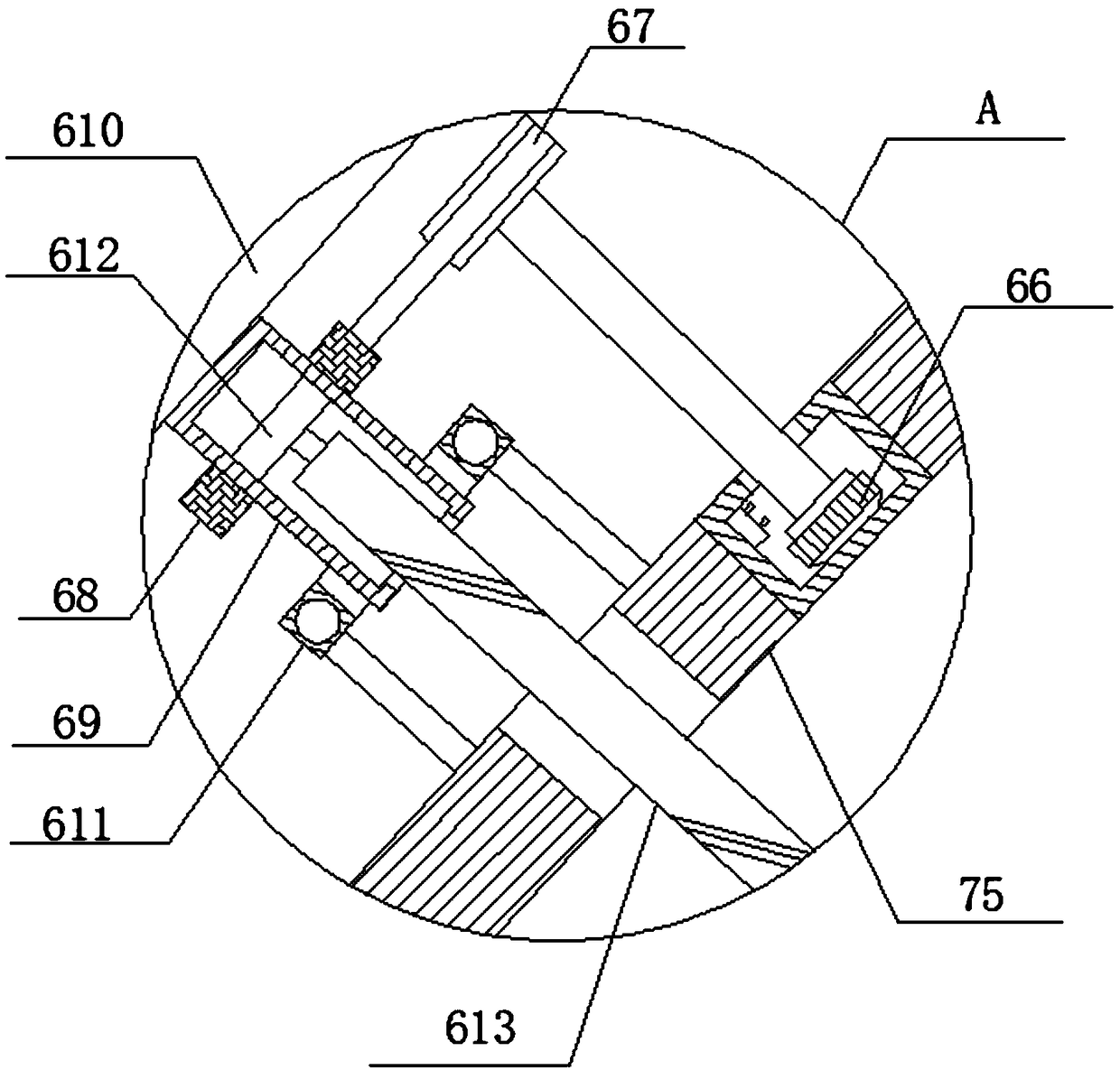

[0031] Two L-shaped connecting rods 65 are symmetrically fixedly connected with the side wall of a section of the mixing shaft 62 located in the 2#Ph regulating tank 6, and a connecting rod 614 is slidably inserted into the horizontal section of the L-shaped connecting rod 65, and one end of the connecting rod 614 is fixed One end of the treatment brush 615 is connected, the end of the L-shaped connecting rod 65 located below the connecting rod 614 is fixedly connected with a stopper, the other end of the treatment brush 615 is against the inner side wall of the 2#Ph regulating tank 6, and the other end of the connecting rod 614 One end of the threaded rod 613 is rotatably connected to the upper side, and the other end of the threaded rod 613 threaded through the vertical section of the L-shaped connecting rod 65 to reach above the L-shaped connecting rod 65 and threadedly sleeved with a sleeve 69. The threaded rod 613 is located in the sleeve. A piston 612 is rotatably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com