Recycled water reusing processing system

A treatment system and reclaimed water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as increasing the amount of water resources, incomplete sewage treatment, and wasting time , to achieve the effect of reducing personnel shifts and labor intensity, facilitating control and automatic management, and avoiding unnecessary operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

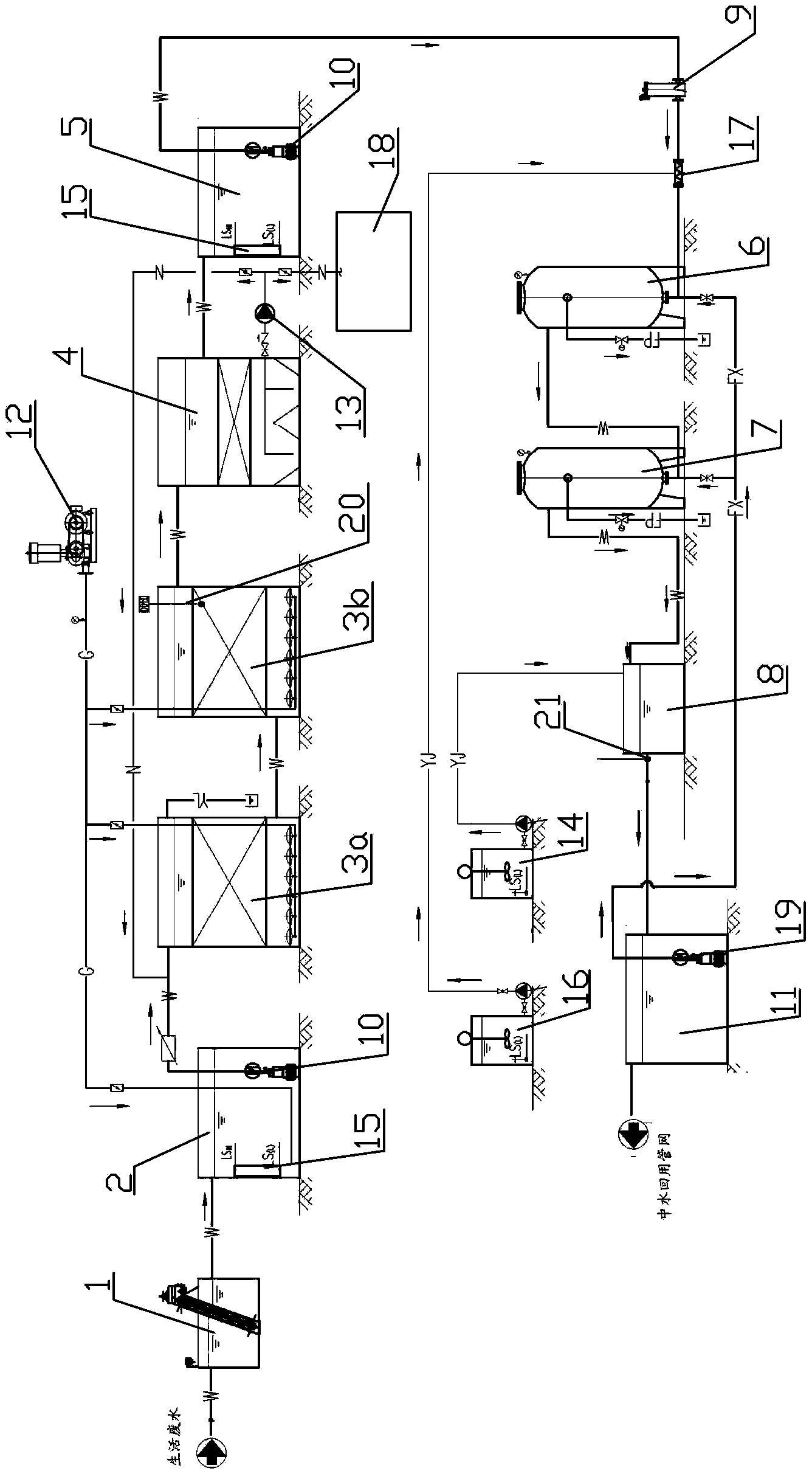

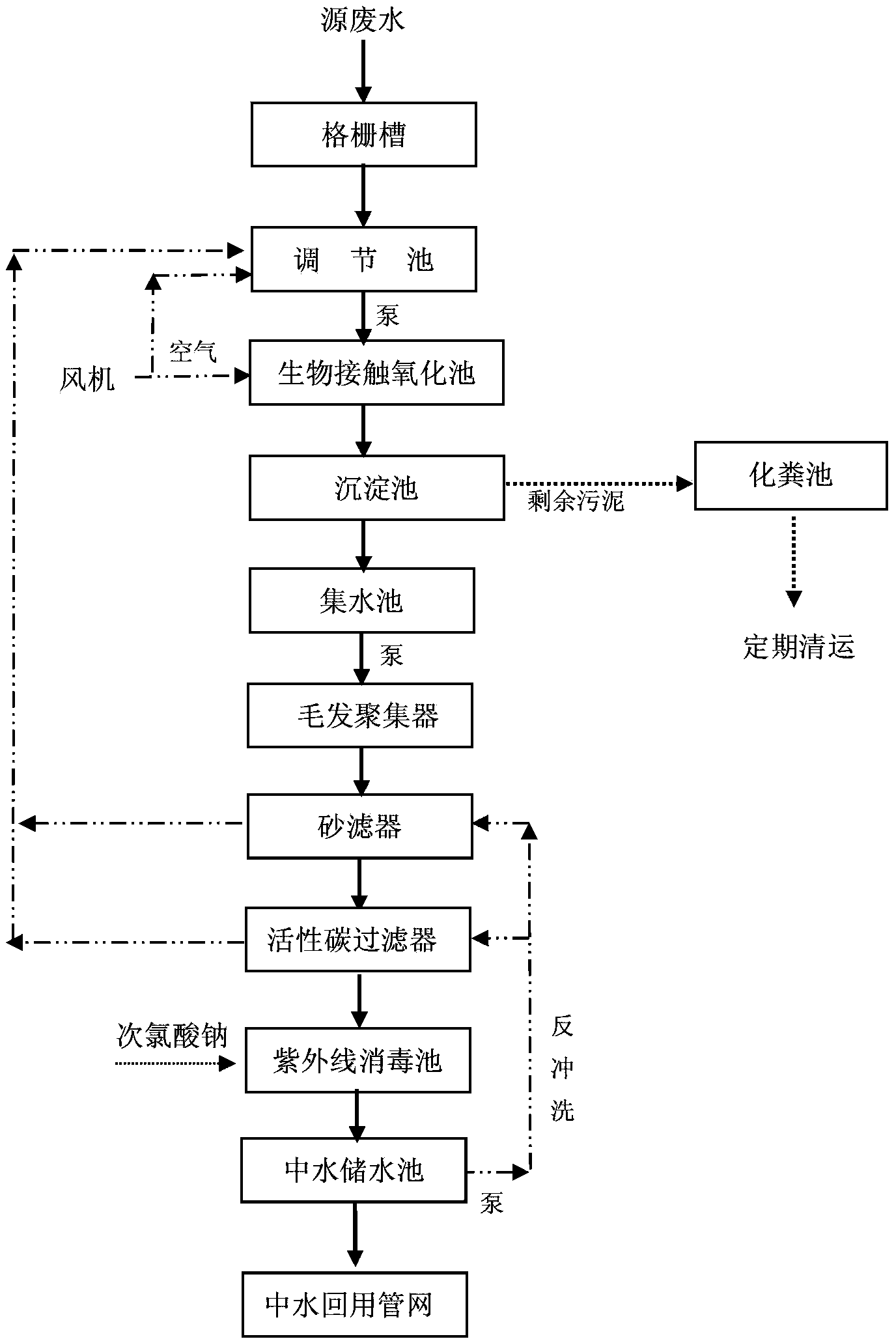

[0038] like figure 1 and figure 2 As shown, a reclaimed water reuse treatment system includes a grid tank 1, a regulating tank 2, a biological contact oxidation tank, a sedimentation tank 4, a water collection tank 5, a sand filter 6, and an activated carbon filter connected sequentially through pipelines according to the wastewater flow direction. Device 7, ultraviolet disinfection tank 8, the grid groove 1 is communicated with the waste water drainage pipeline, the water outlet of the ultraviolet disinfection tank 8 is communicated with the reclaimed water pipe network, and the regulating tank 2 is communicated with the biological contact oxidation tank on the pipeline A hair collector 9 is provided, and a lifting water pump 10 and a float level controller 15 connected to the control end of the lifting water pump 10 are all provided in the regulating pool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com