Patents

Literature

36results about How to "Extend cleaning intervals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical granulation processing method for quartz surface

A method for chemically and roughly treating a quartz surface overcomes the defects of the prior art in which the treatment to the quartz surface easily leads to damage and influences the size accuracy of the quartz product. The method is as below: at a normal temperature and a normal pressure, immersing a quartz product into a container filled with a treating fluid so as to undergo reaction after the surface of the quartz product is polished, taking out the quartz product after two-hour reaction, and immersing the quartz product into the treating fluid again so as to repeat the preceding reaction till the roughness Ra of the surface of the quartz product is equal to 1.5 micrometers to 4.5 micrometers after attachments on the surface of the quartz product is eliminated with deionized water. The treatment process has reasonable design, involves simple devices and is easy to be operated, and the obtained quartz product has uniform surface roughness which is free from the influence of the shape. During the participation in the CVD reaction, the crazing and the shedding of a deposited film on the quartz surface is effectively reduced so as to reduce the possibility of pollution to the reaction cavity, to remarkably improve the finished product rate and the production efficiency, and then further to prolong the service life of the quartz product, save time, reduce consumption and reduce production cost.

Owner:SHENYANG HANKE SEMICON MATERIALS

Disc-type micro-filter and filtering method thereof

InactiveCN105498335AHigh filtration accuracyHigh speedStationary filtering element filtersEngineeringFilter methods

The invention relates to a filter, especially to a disc-type micro-filter and its filtering method. The disc-type micro-filter comprises a box body, inside which a water inlet treatment cavity and a water outlet cavity are arranged. The water inlet treatment cavity and the water outlet cavity are isolated from each other through an overflow plate. The bottom of the water inlet treatment cavity is provided with a water outlet horizontal pipe assembly, which is provided with a filter board assembly. The upper part of the box body is provided with a trolley assembly, which slides along the upper part of the box body. The bottom of the trolley assembly is provided with a backwashing assembly which matches the filter board assembly. The outer wall of the box body is provided with a water inlet, which is communicated with the water inlet treatment cavity. The outer wall of the box body is equipped with a water outlet, which is communicated with the water outlet cavity. The disc-type micro-filter has high structural compactness and has remarkable using effects.

Owner:ZHEJIANG SUNLAND ENVIRONMENTAL TECH CO LTD

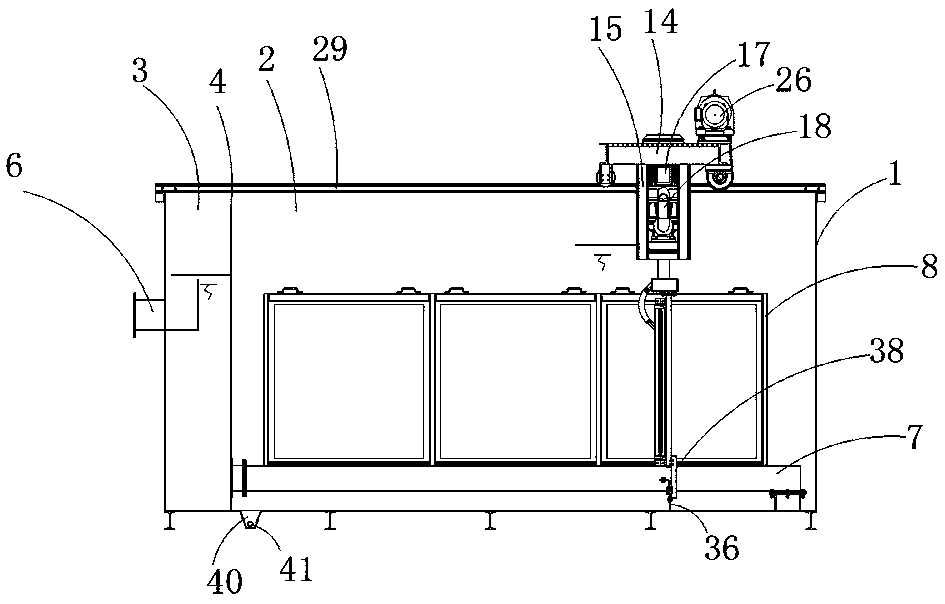

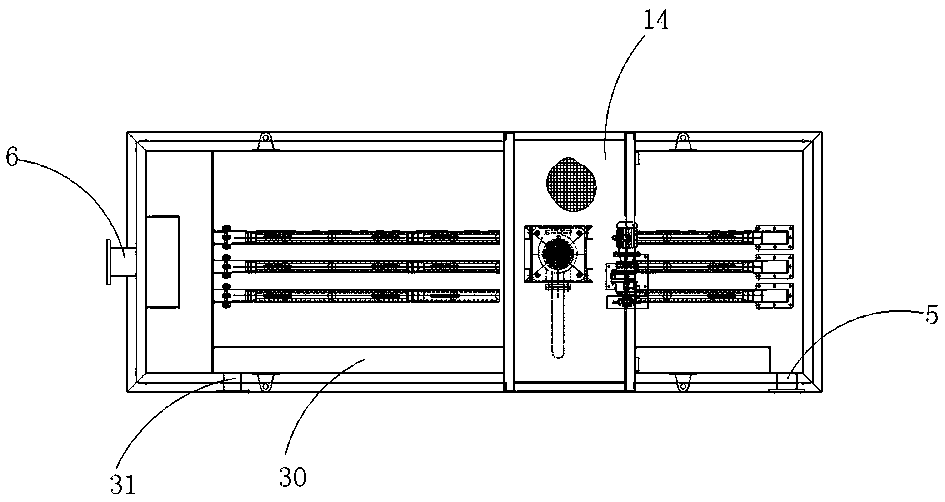

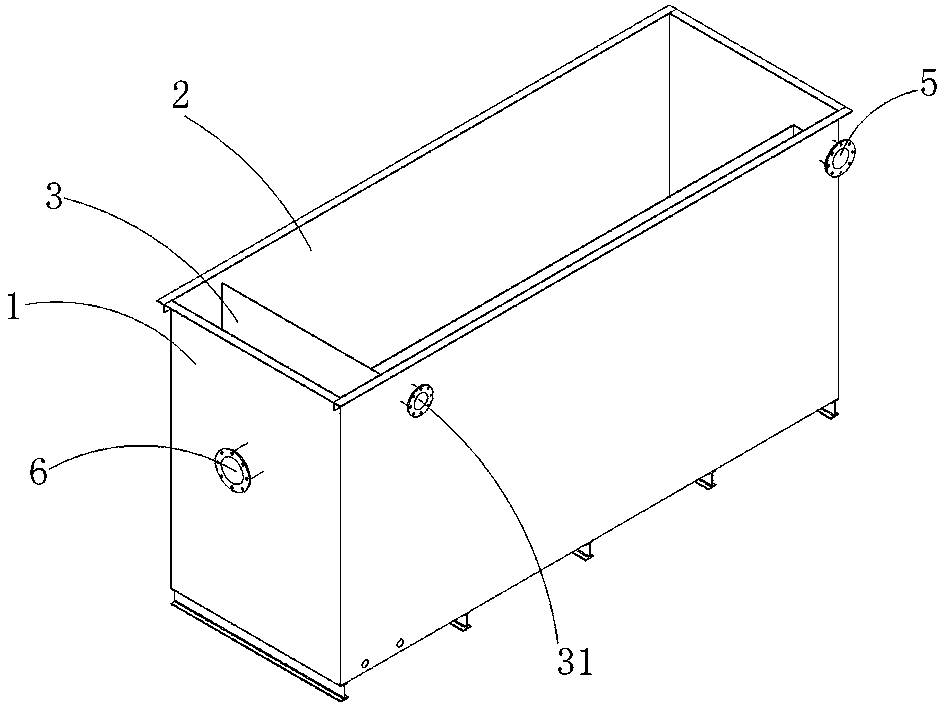

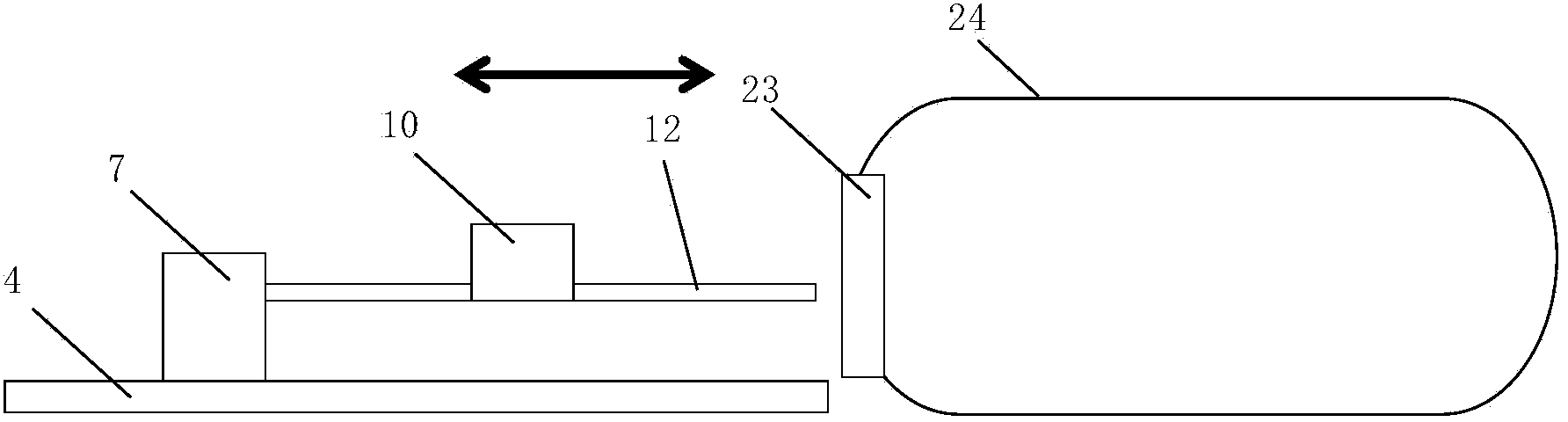

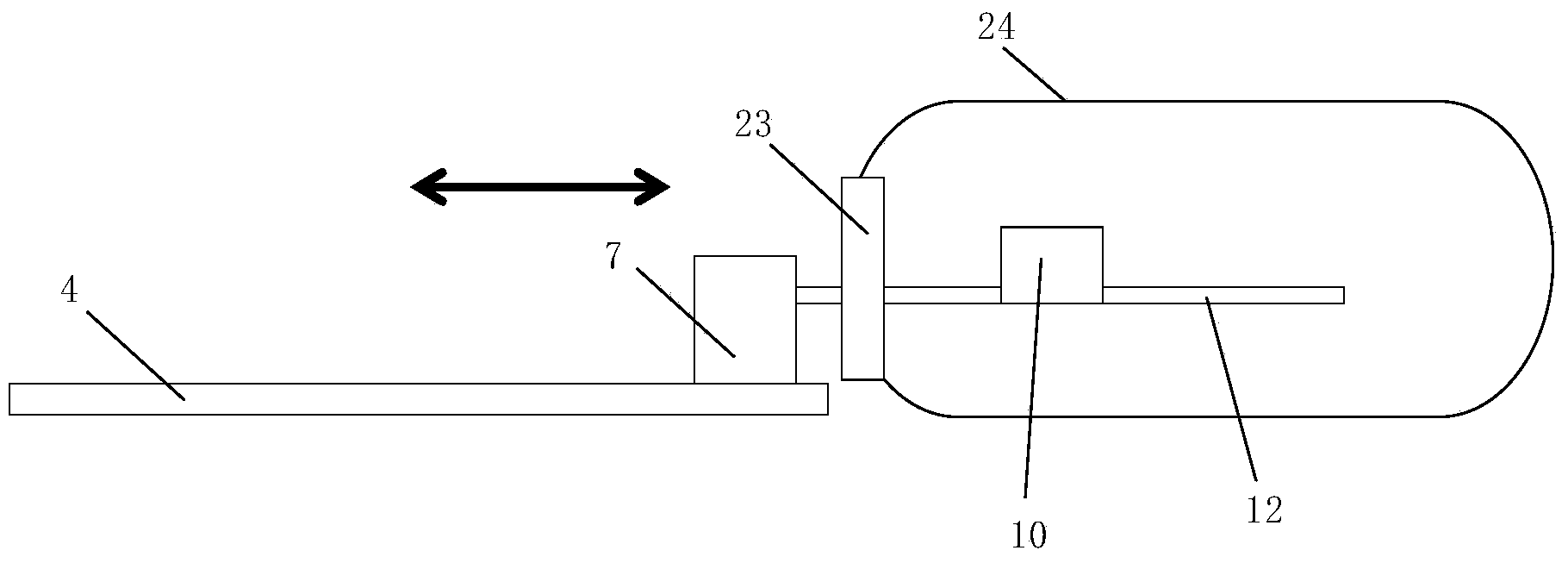

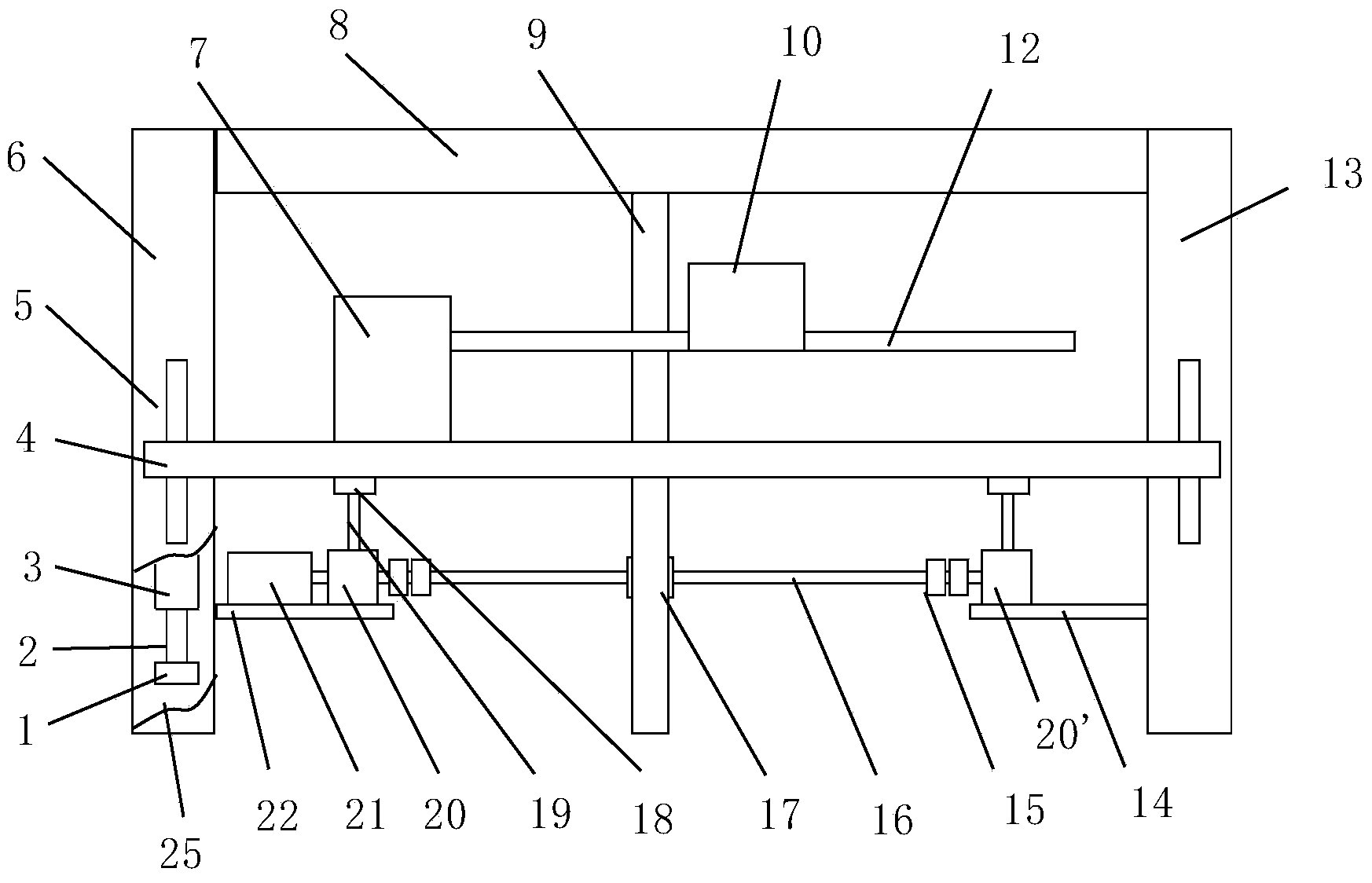

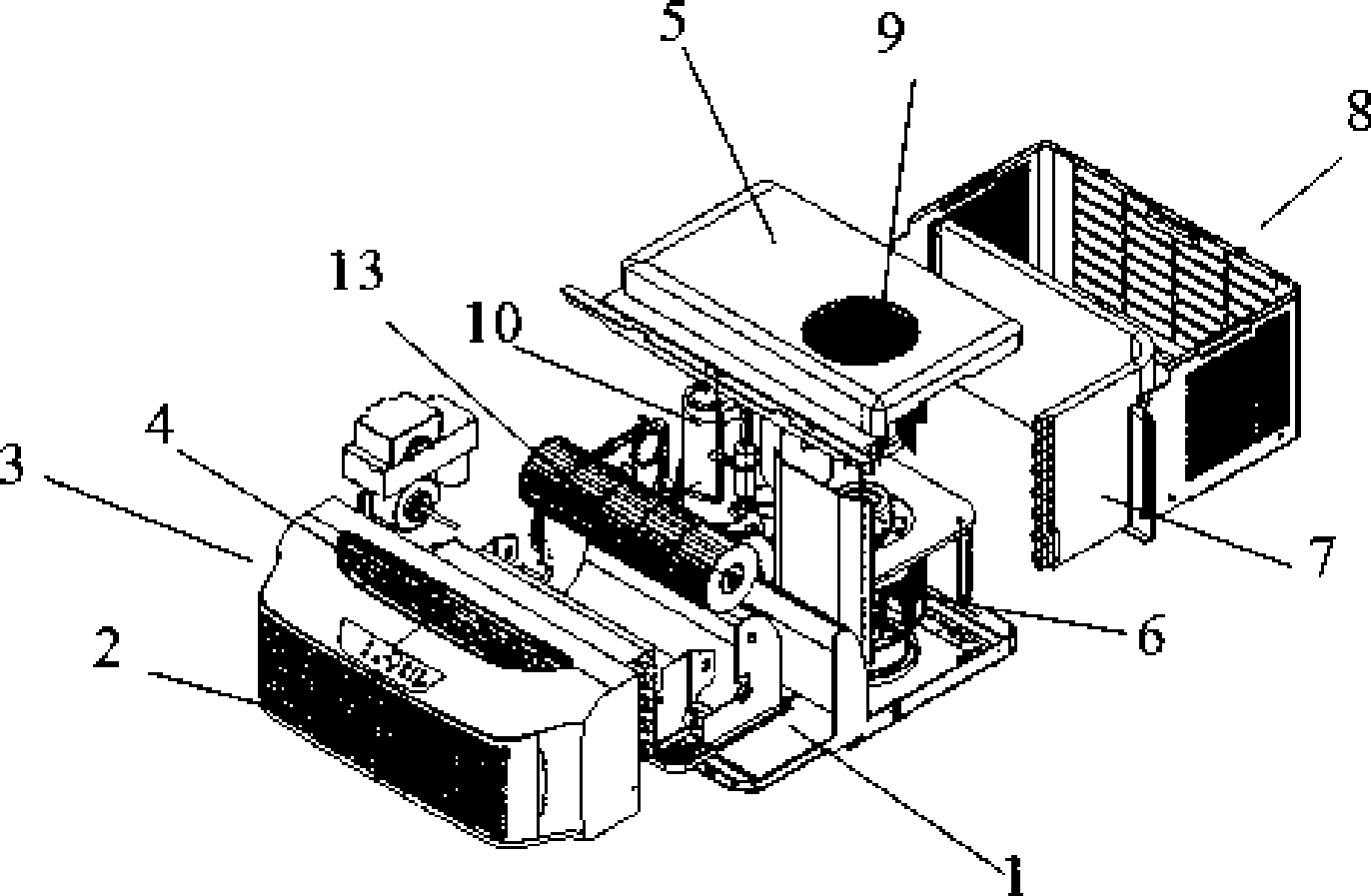

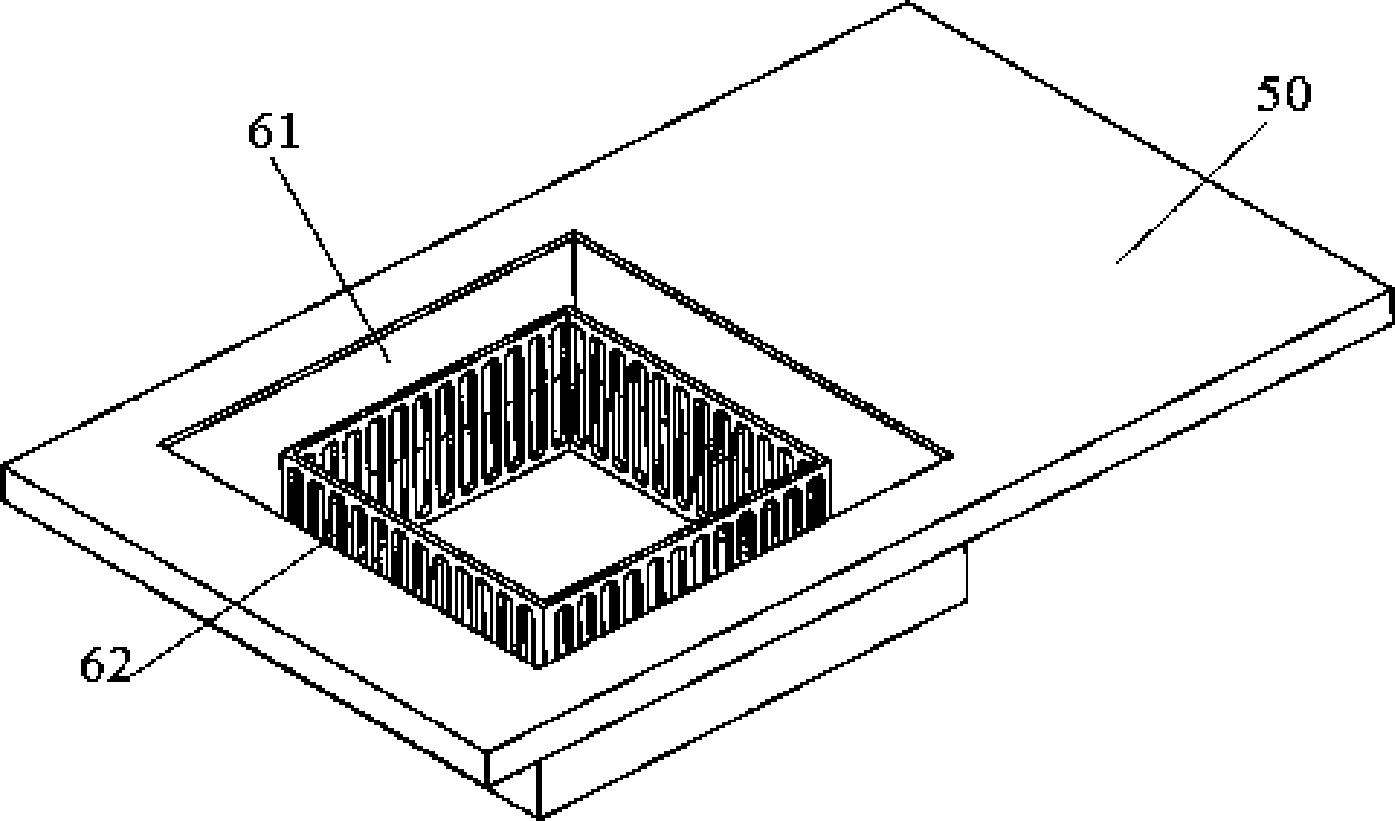

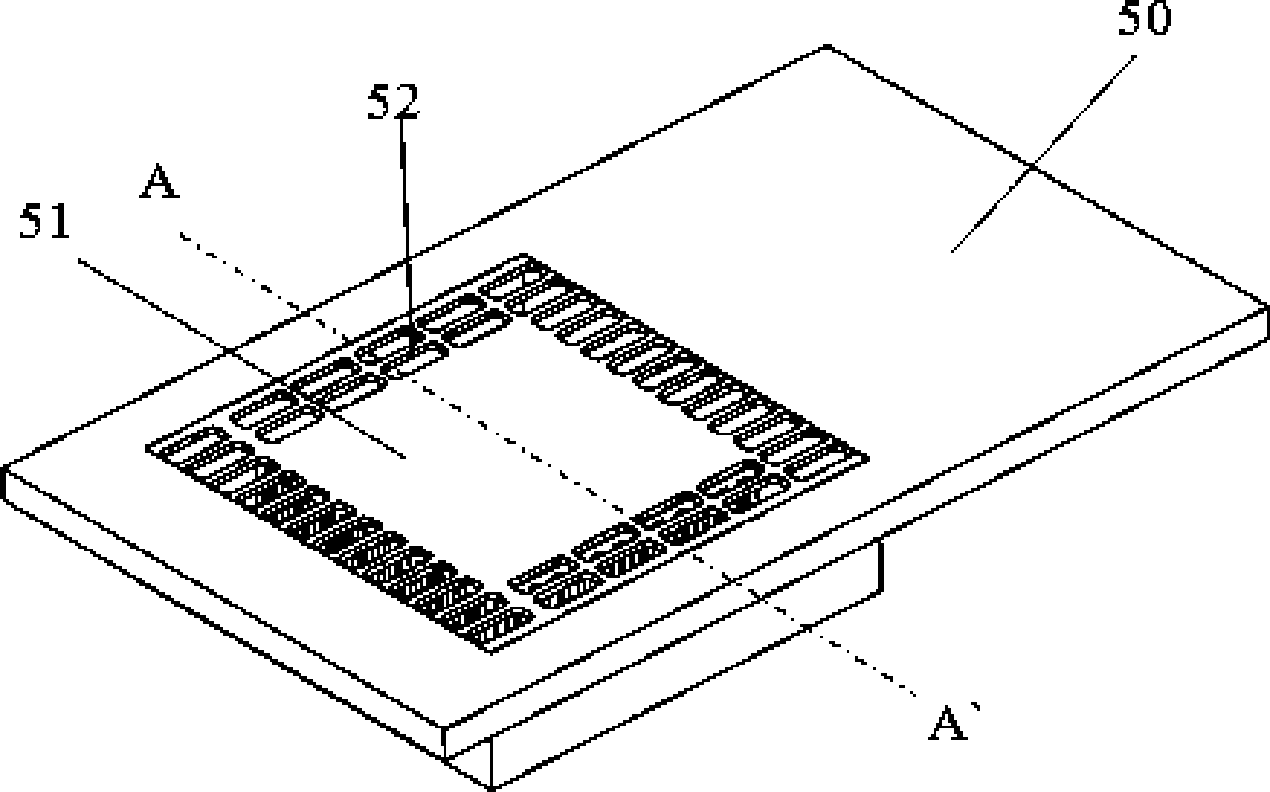

Automatic feeding device of horizontal diffusion furnace

InactiveCN104328502AImprove uniformityEliminate the "shadow effect"Diffusion/dopingCharge manipulationPush pullEngineering

The invention discloses an automatic feeding device of a horizontal diffusion furnace. A cantilever can be controlled to descend by a lifting mechanism, and after the cantilever and a wafer boat loaded on the cantilever are horizontally fed into a furnace tube of the diffusion furnace by a push-pull boat, the wafer boat can be discharged on a support platform in the furnace tube, so that the cantilever can be drawn out of the furnace tube, and only the wafer boat is separately subjected to a diffusion process, therefore, the quality and production efficiency of the diffusion process are improved, and the application and maintenance costs can be saved.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Quartz surface chemical roughening treatment method

InactiveCN110510886AShort processing cycleImprove cleanlinessAmmonium fluorosilicateTreatment period

The invention relates to the technical field of semiconductor quartz part surface treatment, in particular to a quartz surface chemical roughening treatment method, which can effectively reduce consumed time and shorten the surface treatment period of a quartz part for a semiconductor. The method includes the steps of: (1) pretreatment: carrying out surface polishing and annealing treatment on a quartz part needing treatment, and then performing cleaning with deionized water for 5min; (2) preparation of a treatment solution: mixing analytically pure hydrofluoric acid with a solution concentration of 40% and solid analytically pure ammonium fluoride with a solution concentration of 99%, and then adding analytically pure acetic acid with a solution concentration of 99.5% to prepare the treatment solution for standby use; (3) temperature regulation of the treatment solution; (4) reaction treatment: completely immersing the pretreated quartz part in the prepared treatment solution subjected to temperature regulation, and letting a uniform ammonium fluorosilicate attachment gradually form on the surface of the quartz part; (5) flushing; (6) repeating and thickening; and (7) detection ofthe surface roughness.

Owner:SHENYANG HANKE SEMICON MATERIALS

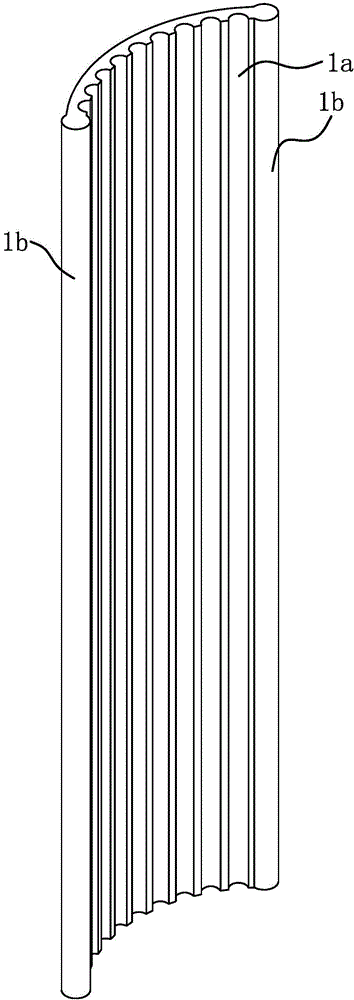

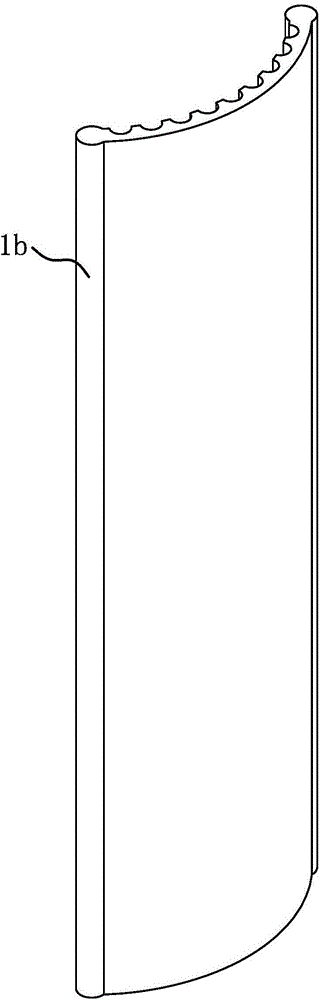

Oil-fog separation blade, oil-fog separation device and application method of oil-fog separation device

ActiveCN104548762ASimple structureReduce manufacturing costDispersed particle separationEngineeringPlane parallel

The invention provides an oil-fog separation blade, an oil-fog separation device and an application method of the oil-fog separation device, belongs to the technical field of working, and aims at solving the problem that oil dirt adhered to an existing filter screen is not easy to clean. The oil-fog separation blade is in a strip sheet shape and the cross section of the oil-fog separation blade is in a circular arc shape; and a concave surface of the oil-fog separation blade is provided with a plurality of grooves which extend along the vertical direction. The oil-fog separation device comprises a framework and the plurality of oil-fog separation blades fixedly arranged on the framework; the plurality of oil-fog separation blades are at least distributed on two planes parallel to a plate surface; the oil-fog separation blades are arranged in parallel; the concave surfaces in the oil-fog separation blades are arranged towards the same plate surface; and the oil-fog separation blades on the two adjacent planes parallel to the plate surface are arranged in a staggered manner. The oil-fog separation device with the oil-fog separation blades has the advantages of convenience for assembling, flexible utilization manner, high oil-fog separation efficiency and the like.

Owner:陈美青

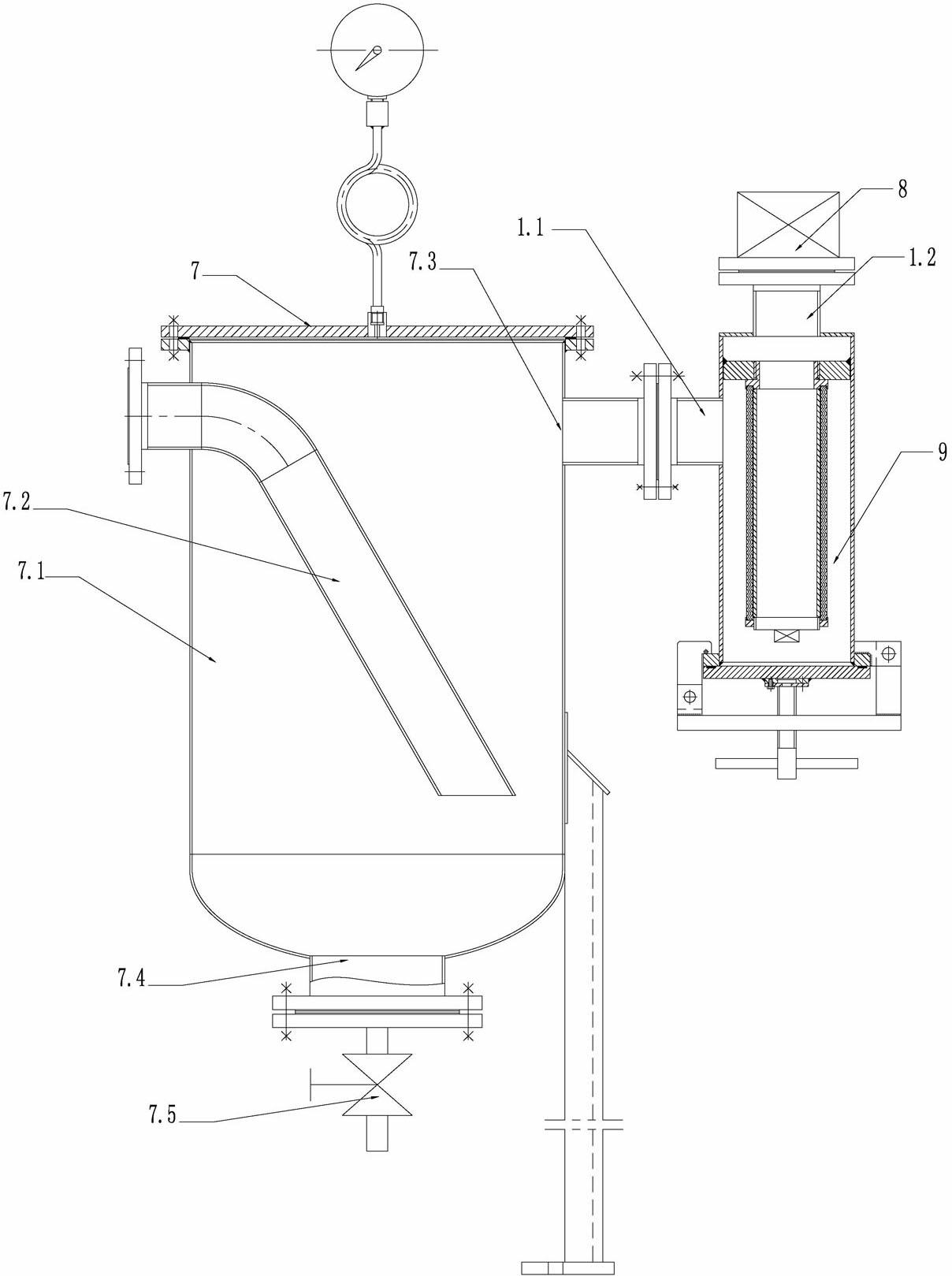

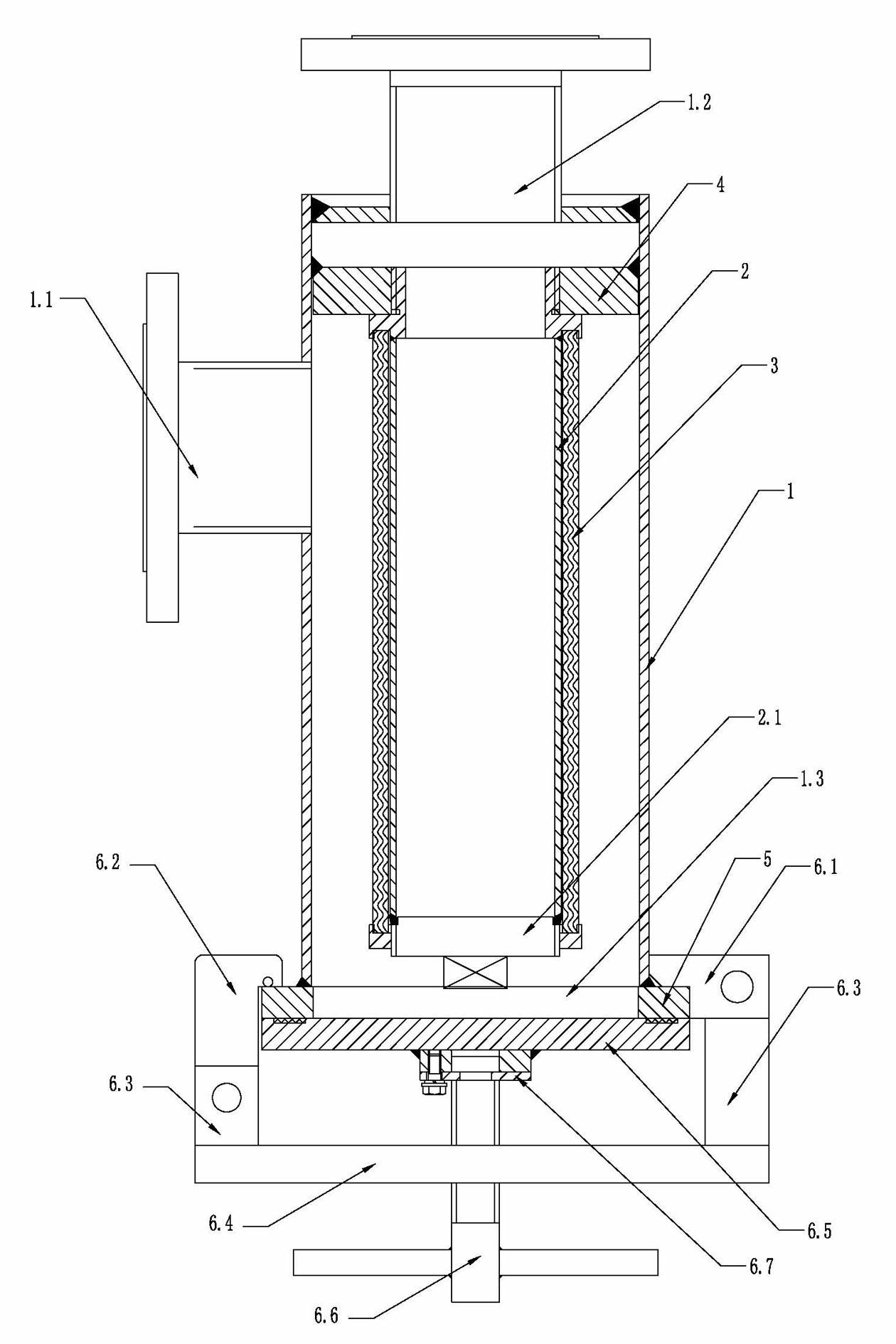

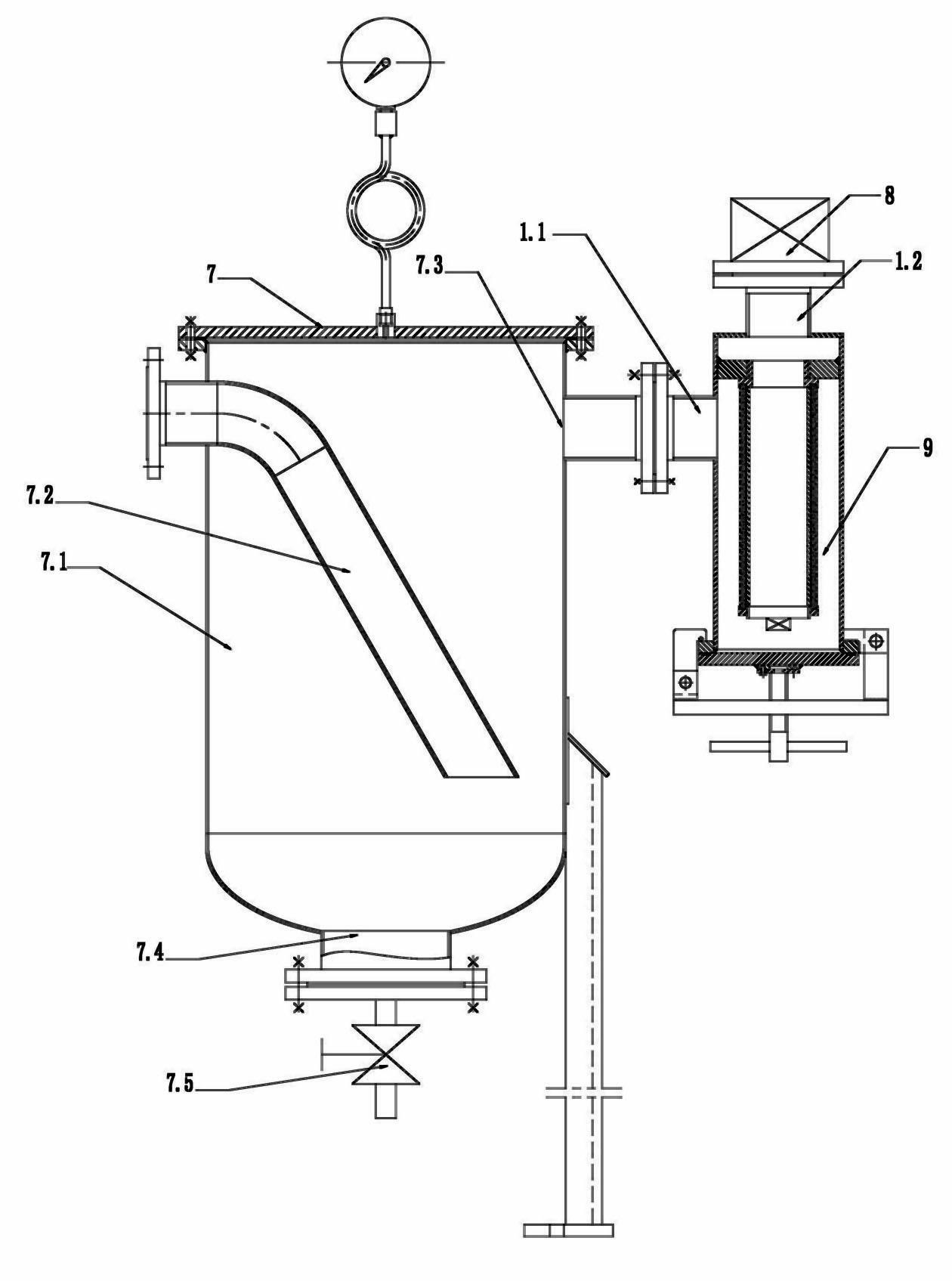

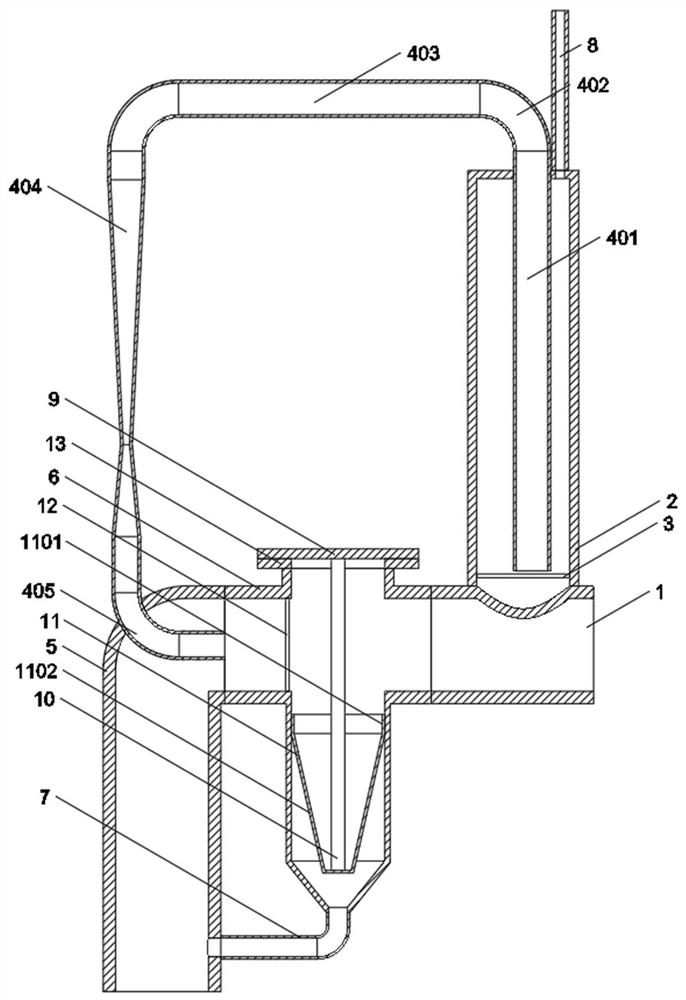

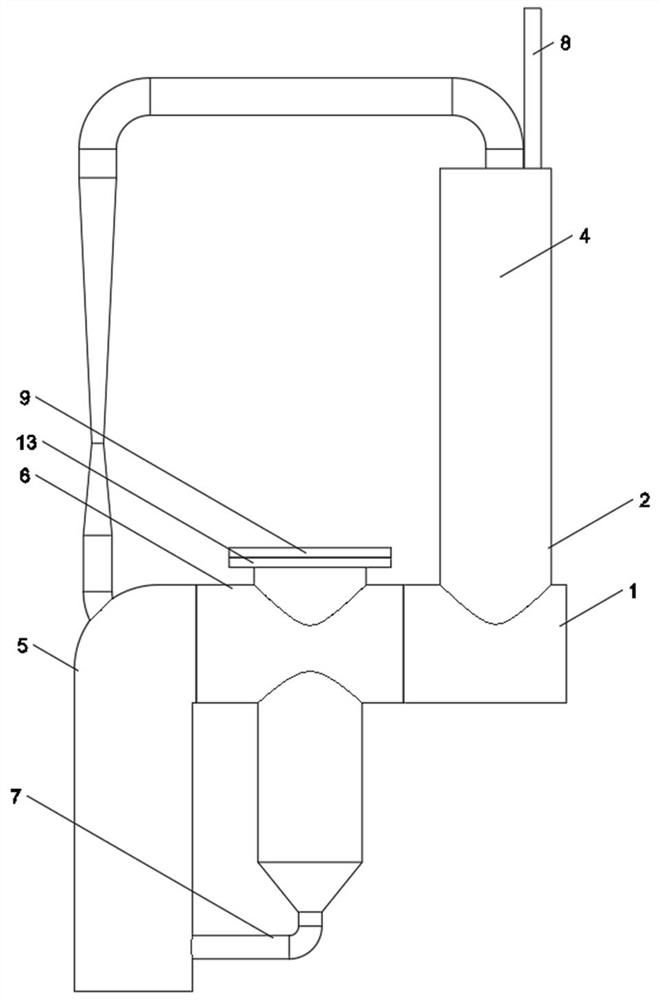

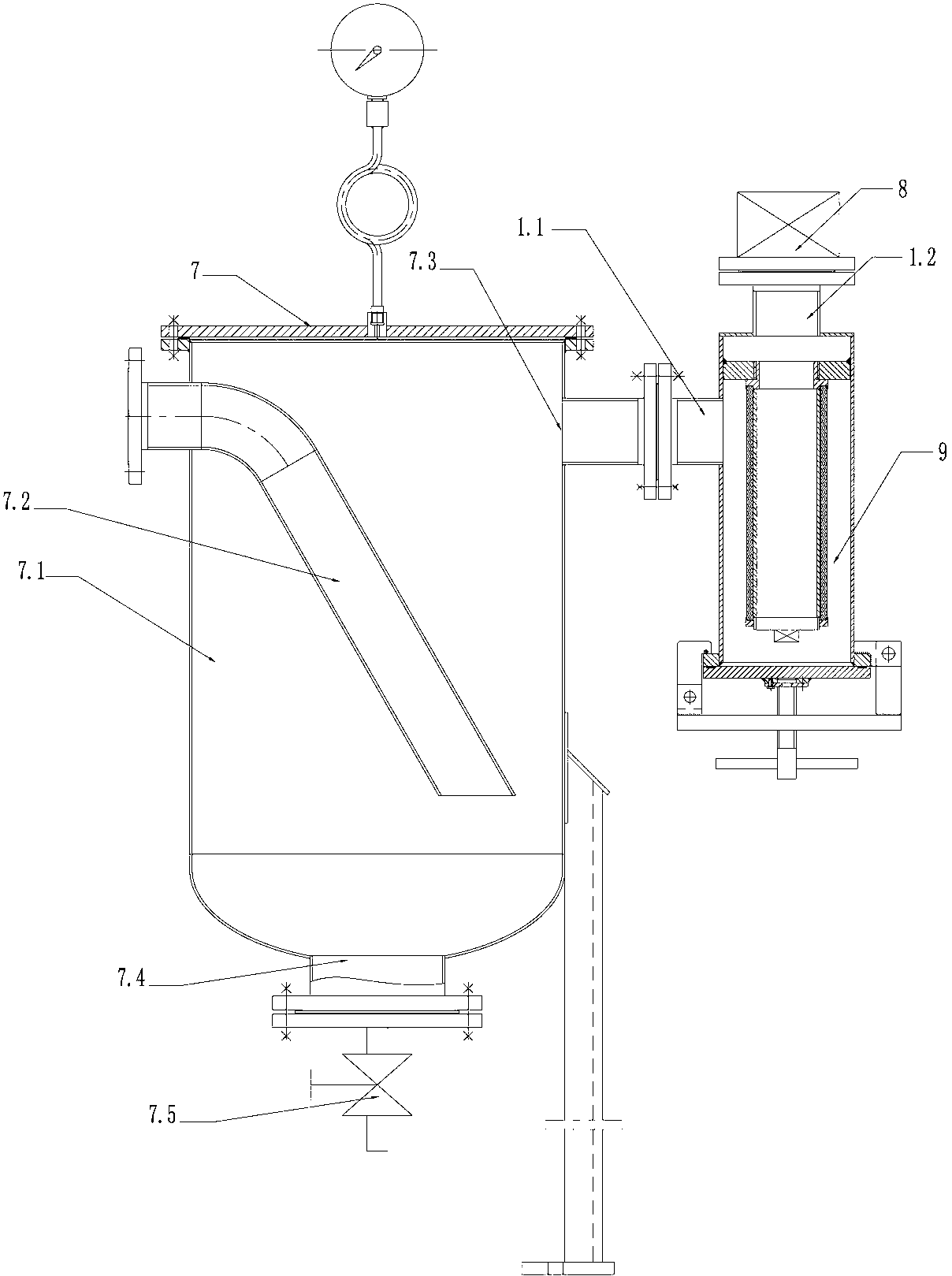

A dust removal device for a vacuum dryer

ActiveCN102284206AExtend cleaning intervalsIncrease productivityStationary filtering element filtersEngineeringUltimate tensile strength

The invention relates to a dust collection device for a vacuum drier. The dust collection device comprises a dust collection barrel and a vacuum pump, and is characterized in that: the dust collection barrel comprises a barrel body and an air inlet pipe; a vacuumizing hole is formed on the side wall of the barrel body; a drain outlet is formed at the bottom of the barrel body; the air inlet pipe is inserted into the barrel body; a dust collector is arranged between the dust collection barrel and the vacuum pump; a dust inlet of the dust collector is connected with the vacuumizing hole of the dust collection barrel; and a vacuumizing interface of the dust collector is connected with the vacuum pump. The dust collection device has the advantages that: when the vacuum drier is used for drying, dust is separated from water completely, the dust collection device is not needed to be cleaned frequently, and the production efficiency is improved while the labor intensity of workers is reduced.

Owner:JIANGYIN CHEM MASCH CO LTD

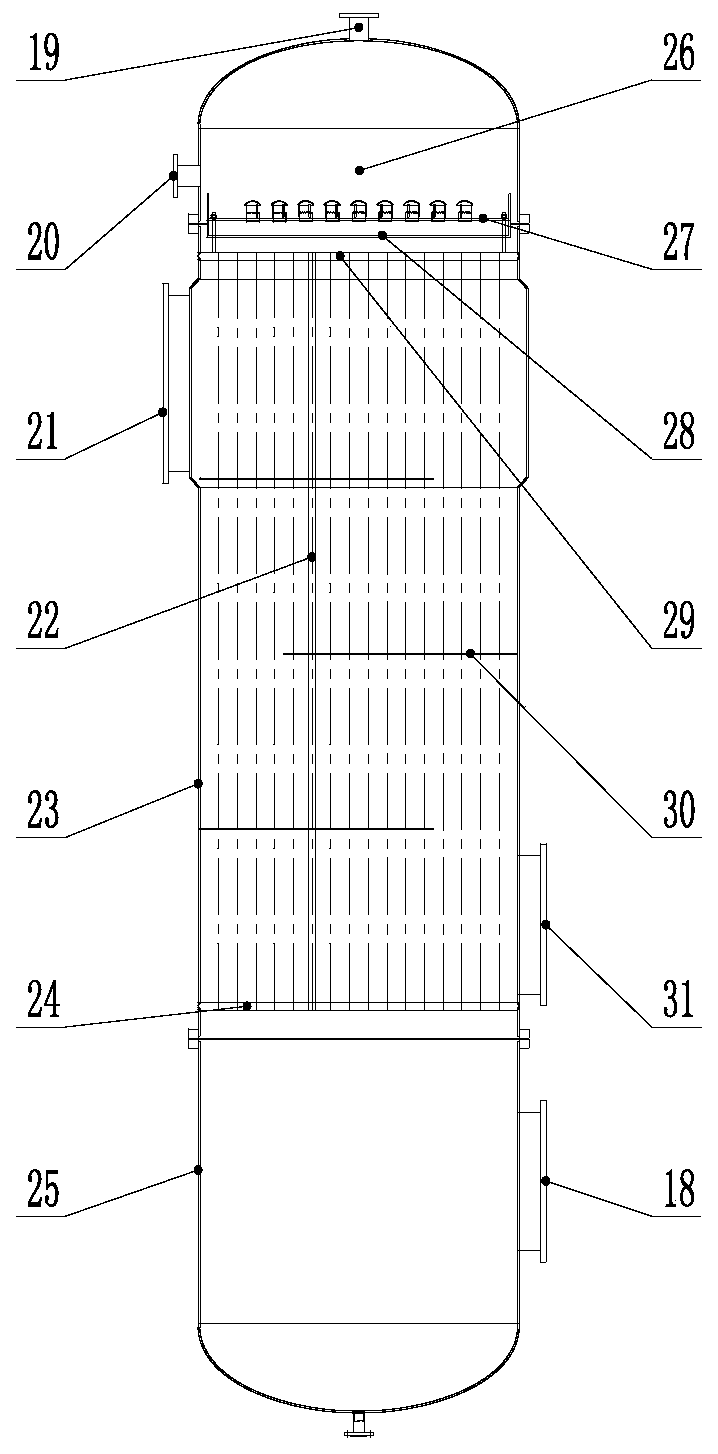

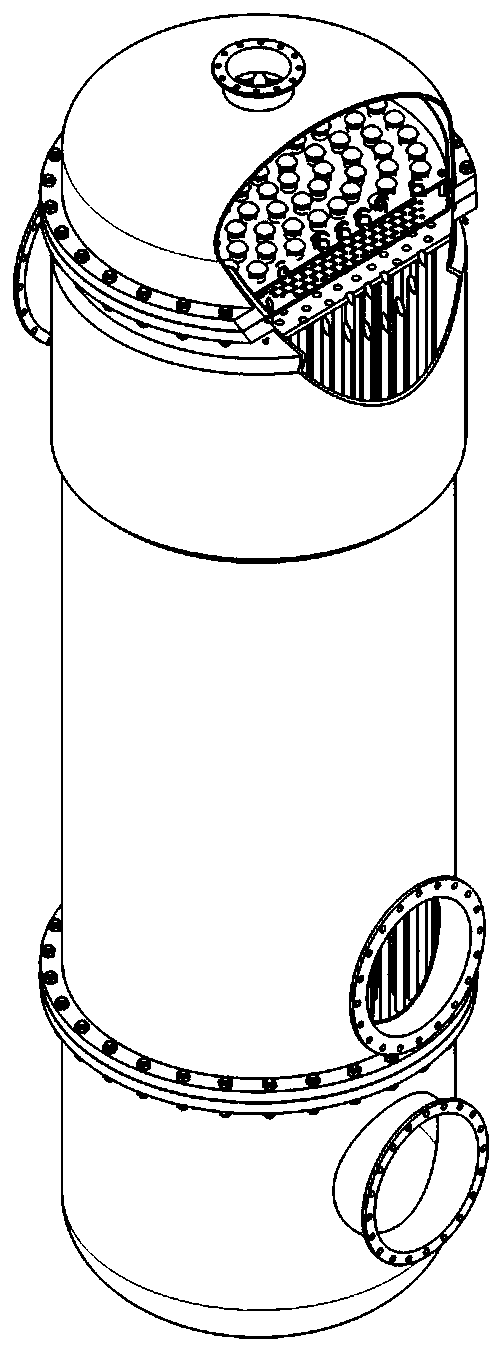

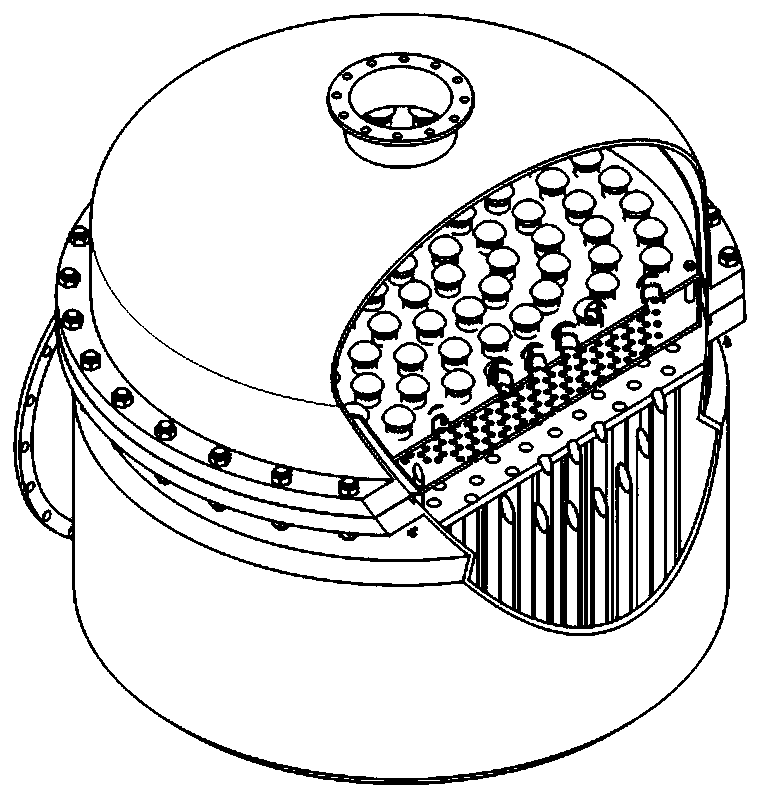

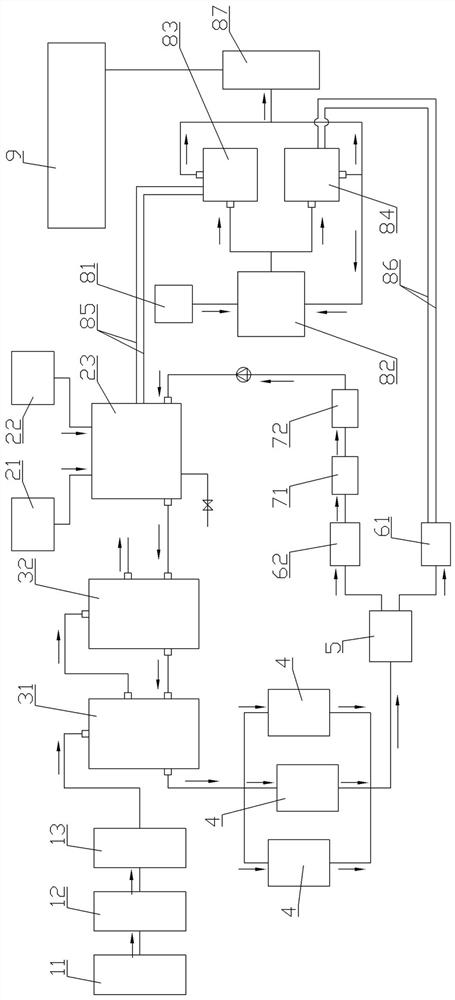

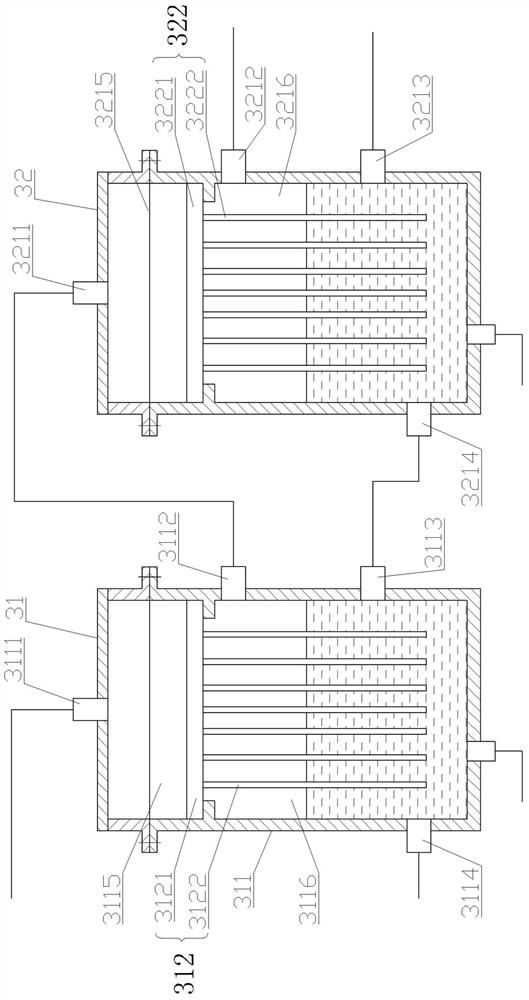

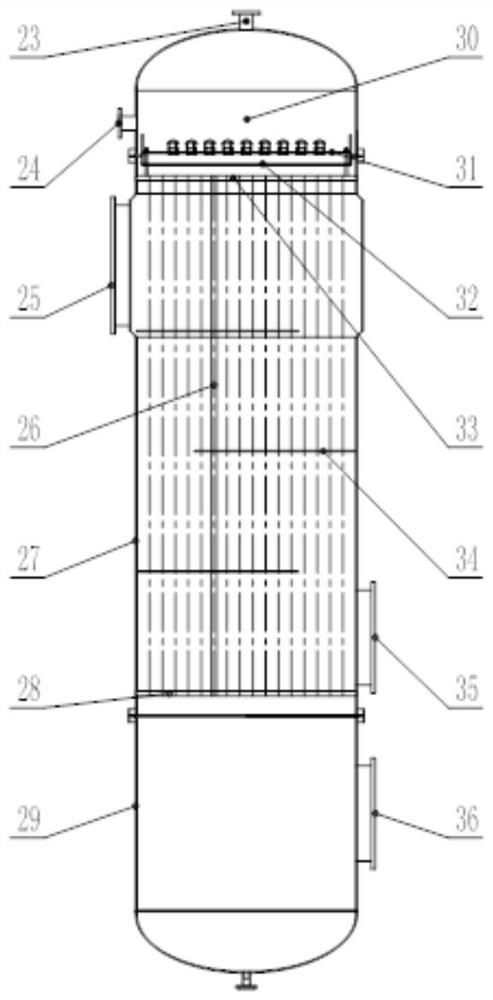

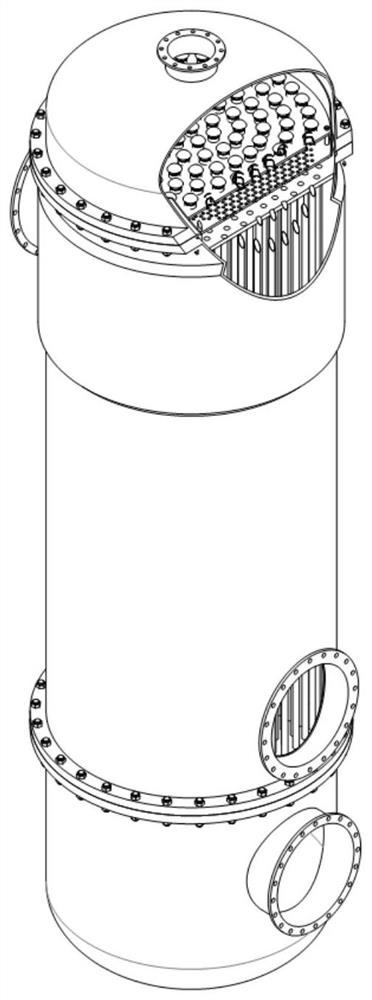

Molasses concentration device and using method and process thereof

ActiveCN111375218ANot easy to gelatinize and hang on the wallSufficient heat exchangeFood thermal treatmentEvaporator accessoriesEconomic benefitsProcess engineering

The invention discloses a molasses evaporation and concentration device and a using method and process thereof. The molasses evaporation and concentration device comprises a first evaporation unit, asecond evaporation unit, a third evaporation unit and a fourth evaporation unit. The first evaporation unit takes secondary steam generated by the second evaporation unit as a heat source, the secondevaporation unit takes secondary steam generated by the third evaporation unit as a heat source, the third evaporation unit takes secondary steam generated by the fourth evaporation unit as a heat source, and the fourth evaporation unit takes secondary steam generated by a wet protein drying process as a heat source, and evaporators of the first evaporation unit, the second evaporation unit, the third evaporation unit and the fourth evaporation unit are all tubular falling film evaporators. The molasses gelatinization wall-hanging phenomenon is obviously reduced, the equipment utilization rateis improved, the production cost of enterprises is greatly reduced, and greater economic benefits are brought to the enterprises.

Owner:SHANDONG KAISTAR MASCH MFG CO LTD

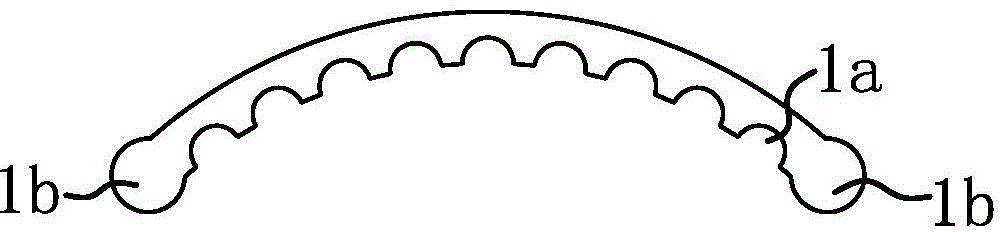

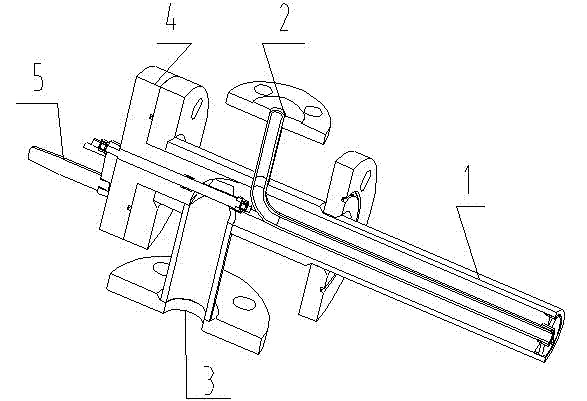

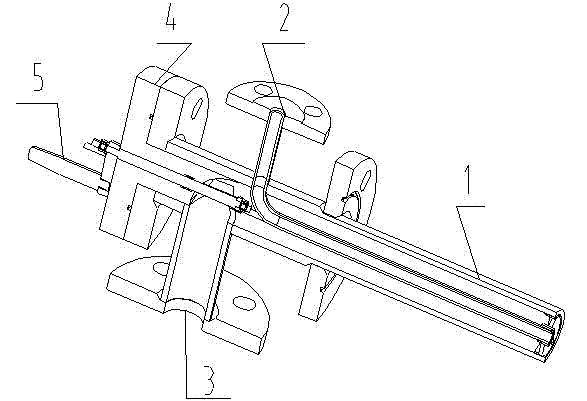

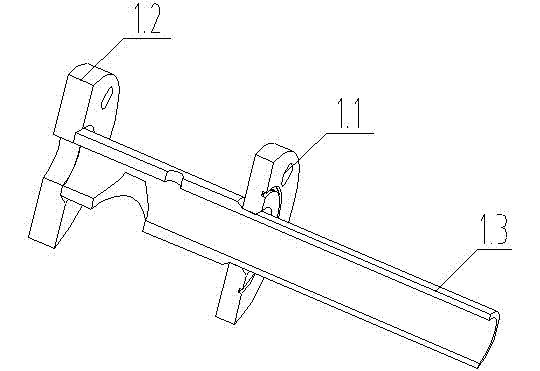

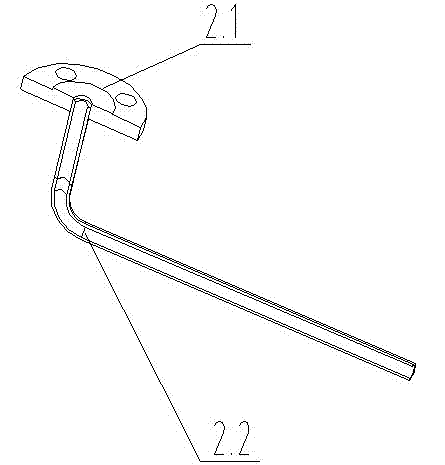

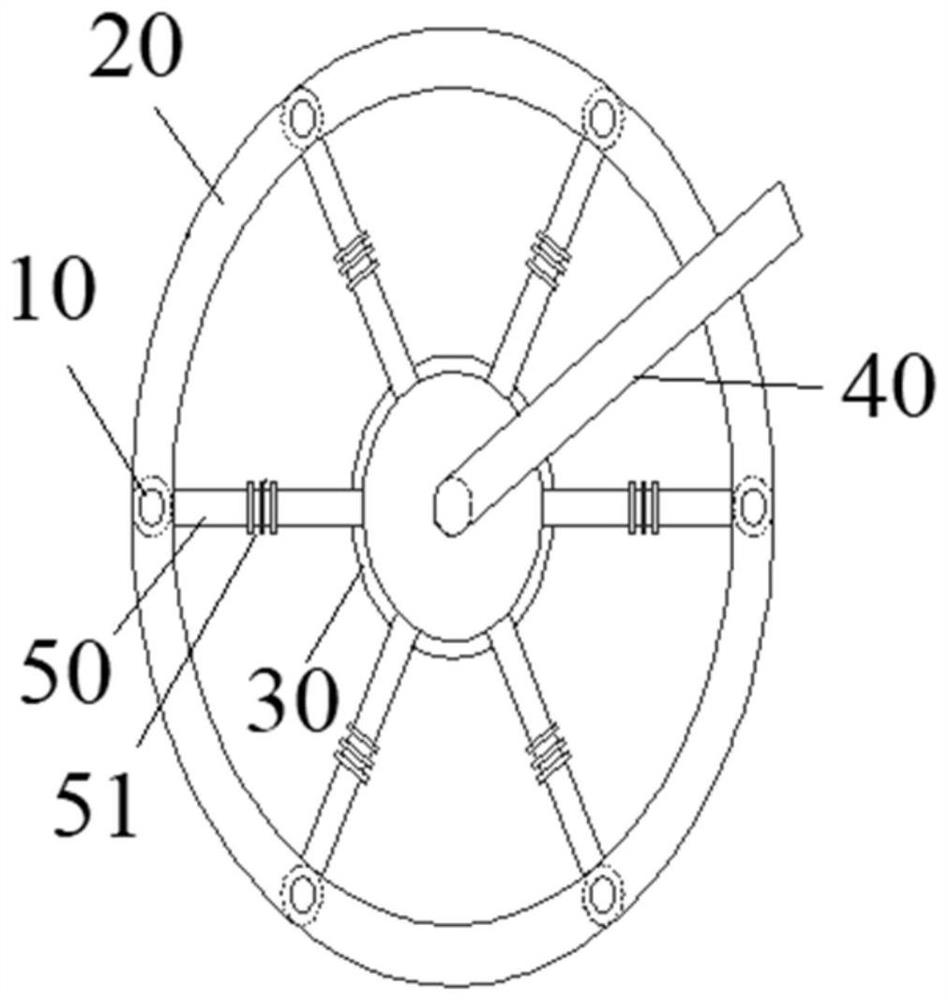

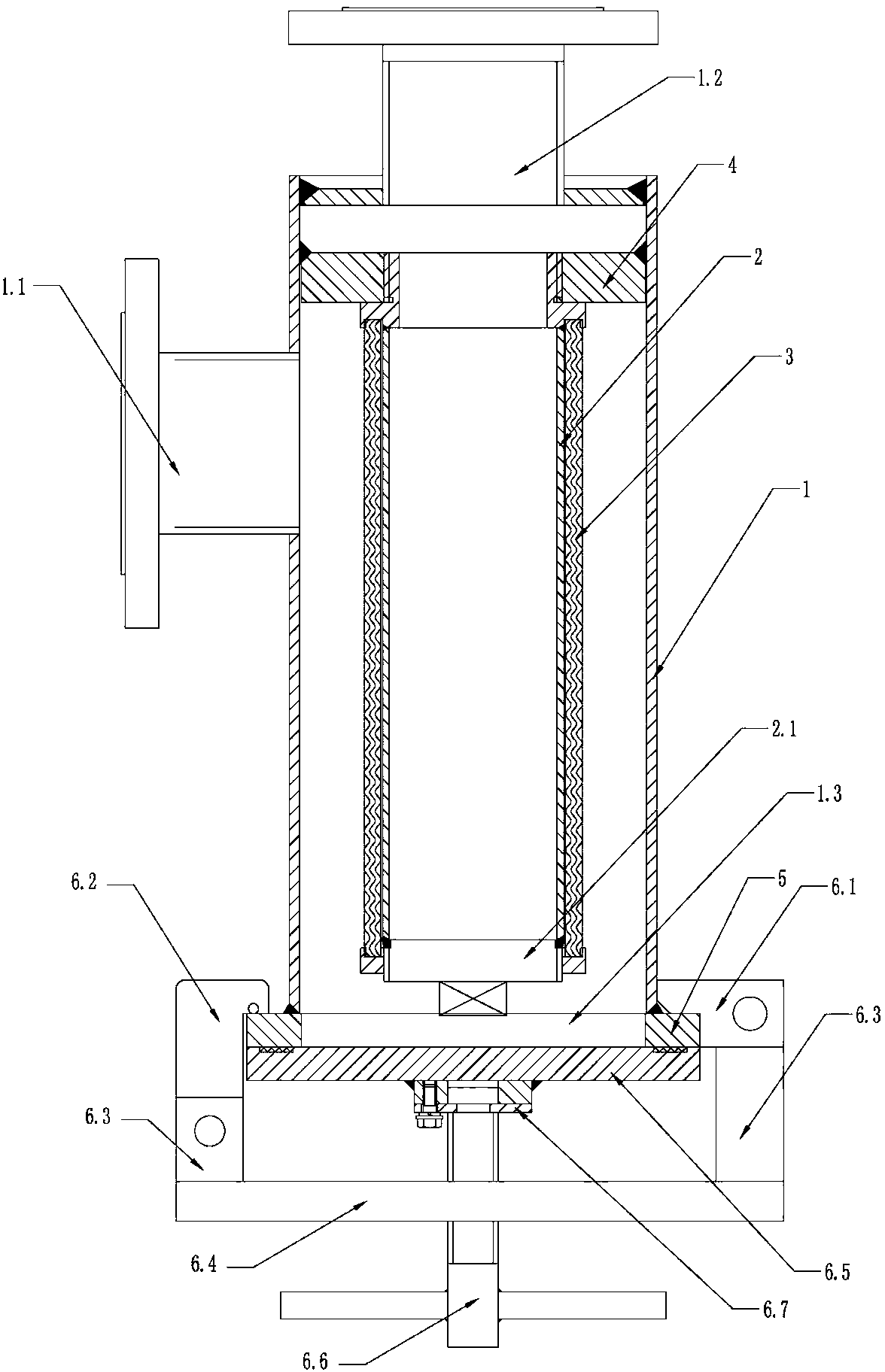

Feeding pipe of reactor for continuous polymerization production of spandex

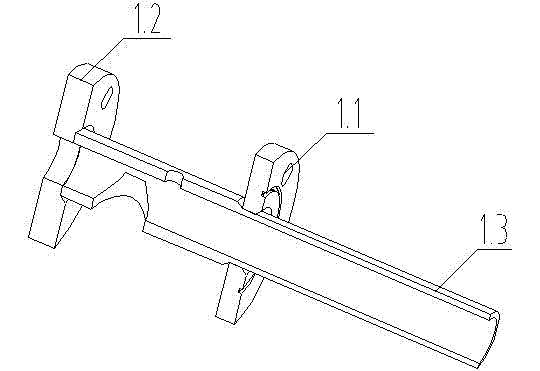

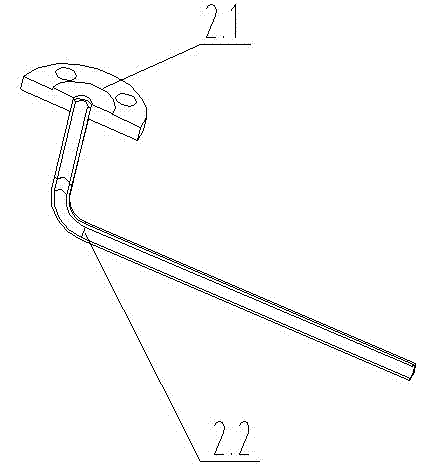

The invention relates to a feeding pipe of a reactor for continuous polymerization production of spandex. The pipe comprises a feeding pipe body (1), a mixed amine feeding pipe (2), a prepolymer feeding pipe (3), an end surface flange cover (4) and a manual doctor blade system (5), wherein the feeding pipe main body (1) comprises a main feeding pipe (1.3), a first flange (1.1) and a second flange(1.2); the mixed amine feeding pipe (2) comprises a mixed amine pipe (2.2) and a third flange (2.1), the third flange (2.1) is mounted at one end of the mixed amine pipe (2.2), and the mixed amine pipe (2.2) is arranged in the main feeding pipe (1.3); the prepolymer feeding pipe (3) comprises a prepolymer feeding branch pipe (3.1) and a fourth flange (3.2); the end surface flange cover (4) is connected with the outer end of the second flange (1.2); and the manual doctor blade system (5) comprises a handle (5.1), a first link rod (5.2), an eccentric crank (5.3), a second link rod (5.4) and a doctor blade (5.5). The feeding pipe of the reactor is reliable in performances, does not need to be cleaned regularly and can prevent the continuous generation of gumming phenomenon during the production.

Owner:JIANGYIN L V CHEM FIBER PROCESS TECH

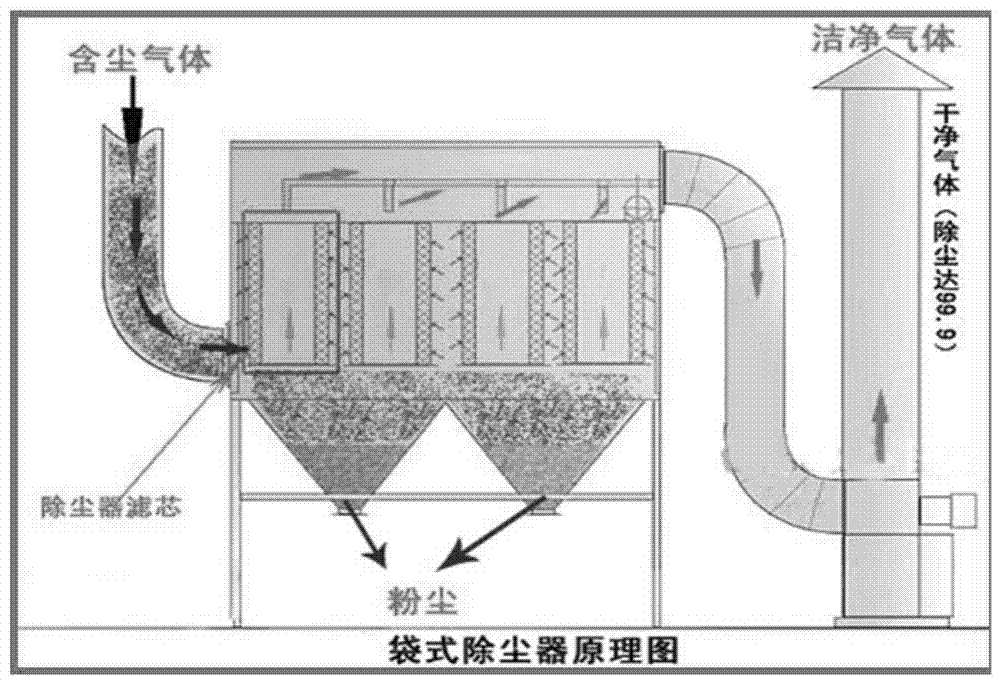

Dust bag type dust removal process under disordered and uneven state

InactiveCN107252600AIncreased cleaning pressure differenceImprove cleaning efficiencyDispersed particle filtrationTransportation and packagingStart stopBiochemical engineering

The invention discloses a dust bag type dust removal process under the disordered and uneven state. A fold filter bag is designed to replace a traditional round or oval cloth bag, a specialized cage bone is used cooperatively, and the filter area of the filter bag is increased by more than 60%; meanwhile, a mass-flow low-frequency pulse valve blast cleaning technology is adopted, the dust-removal pressure differential is increased to 1.2kPa, the pulse frequency is reduced to 30 seconds / time, dust-removal frequency is greatly lowered, service life of the filter bag can be prolonged, times for operating maintenance are reduced, and dust-removal efficiency is improved obviously; therefore, through application of the Internet of Things technology, systems in measurement of dust concentration, start-stop of dust removal equipment, monitoring and inspecting and the like can be automatically controlled, and labor cost is reduced.

Owner:湖北宜化江家墩矿业有限公司

Cooling device in rotating drum core part for preventing latex bonding in concentration and separation process

The invention discloses a cooling device in a rotating drum core part for preventing latex bonding in a concentration and separation process. The rotary drum core cooling device comprises a machine base, a rotating drum positioned in the machine base and a vertical shaft connected with the rotating drum core part; the cooling device is characterized in that a core part cooling device body is arranged on the surface of the rotating drum core part, centripetal pumps are arranged at the joint of the vertical shaft and the rotating drum core part, and the output ports of the centripetal pumps arearranged in the axial direction of the rotating drum and communicate with inner flow channels leading to the core part cooling device body; and the rotating drum core part is further provided with a backflow channel communicating with the core cooling device body, and an atomizing nozzle is arranged at a liquid outlet of the backflow channel. According to the cooling device, centrifugal force is utilized to enable a cooling liquid to enter the rotating drum core part to be cooled through the interior of the rotating drum core part, so that the phenomena of space occupation by additional cooling auxiliary parts and complex structure are reduced; and the rotating drum core part and the bottom part are subjected to sufficient heat exchange, the atomizing nozzle further cools the space betweena protective cover and the rotating drum, so that generation and growth of latex ball caps are avoided, and the latex separation quality is improved.

Owner:ZHEJIANG QINGJI IND +1

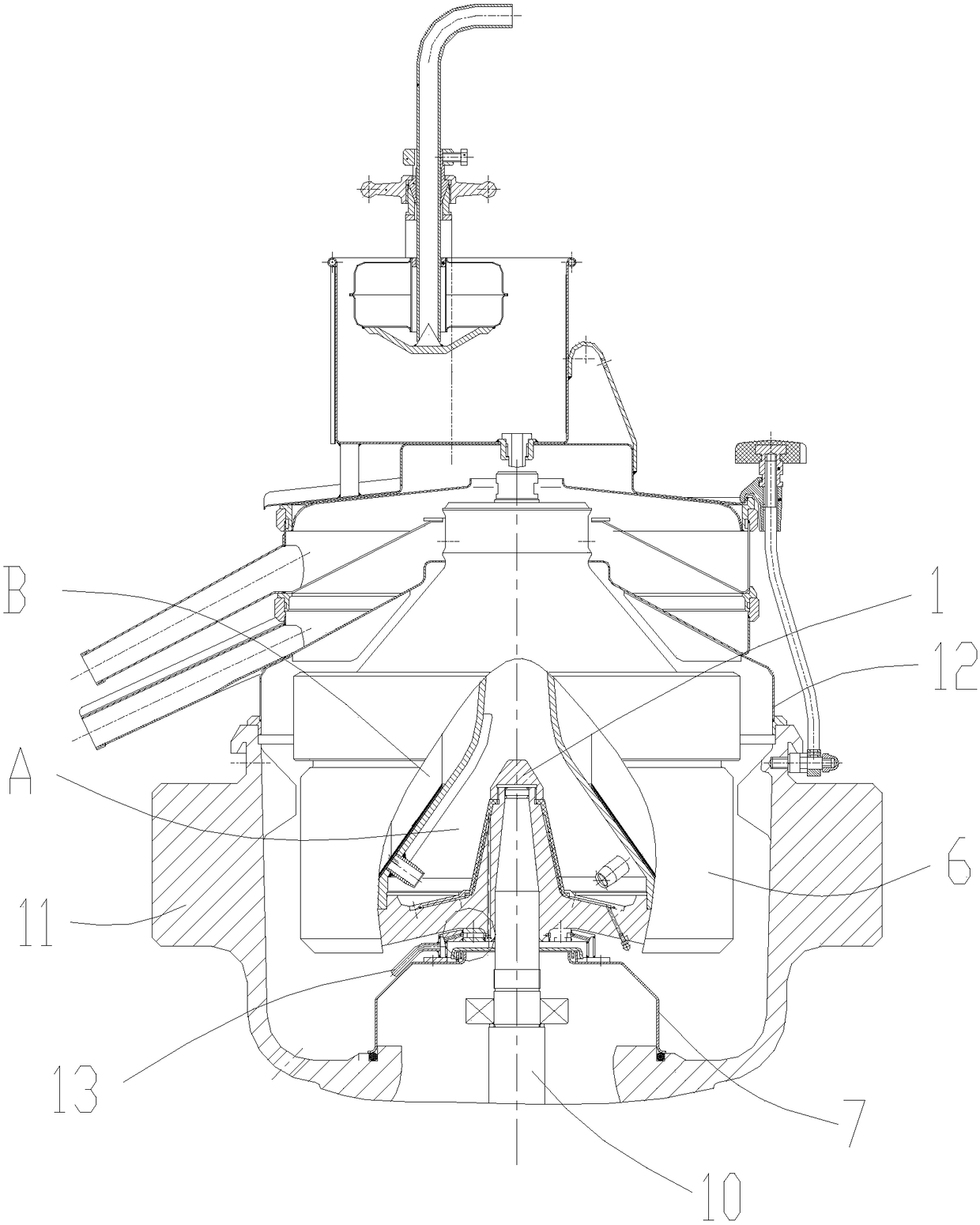

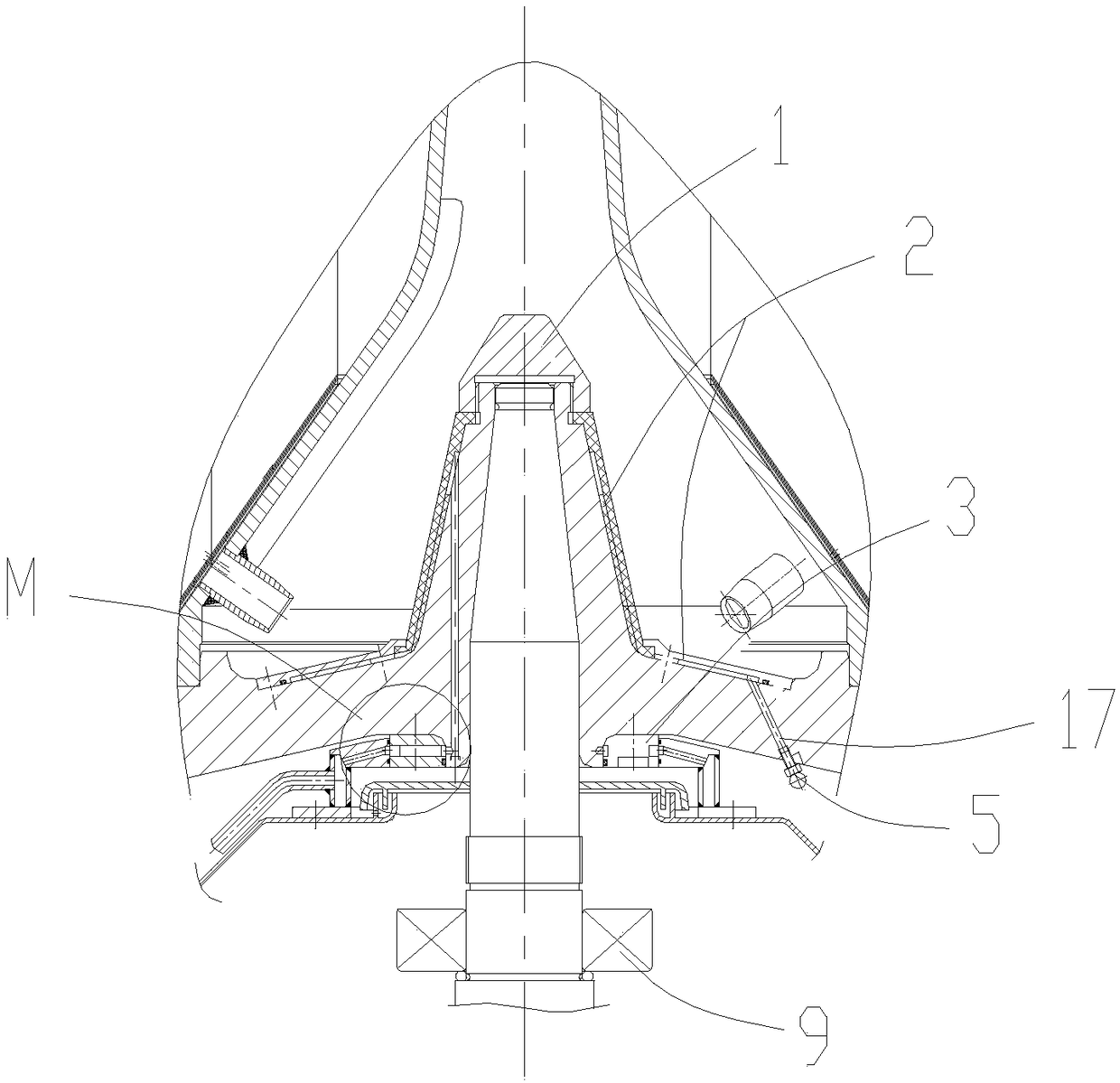

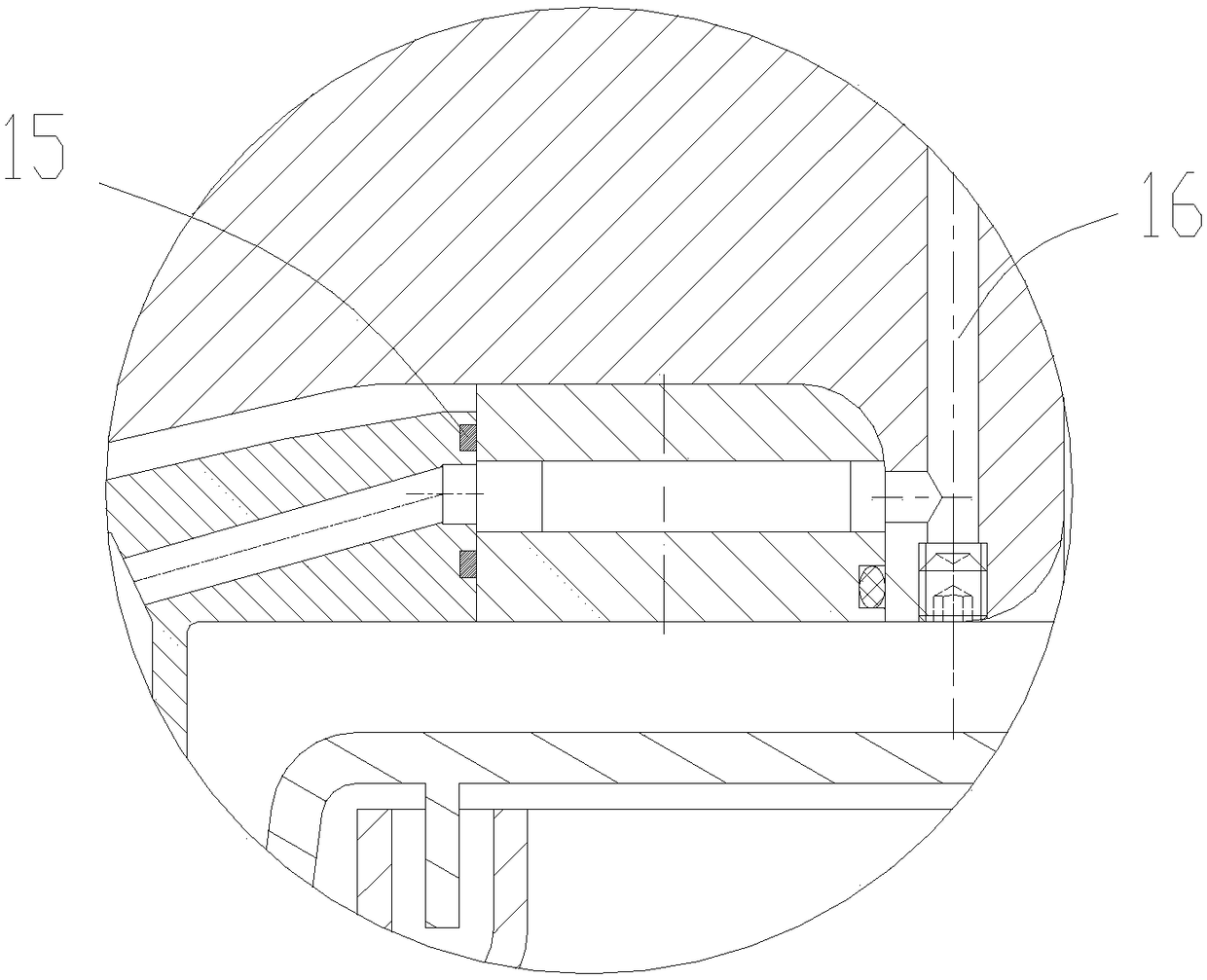

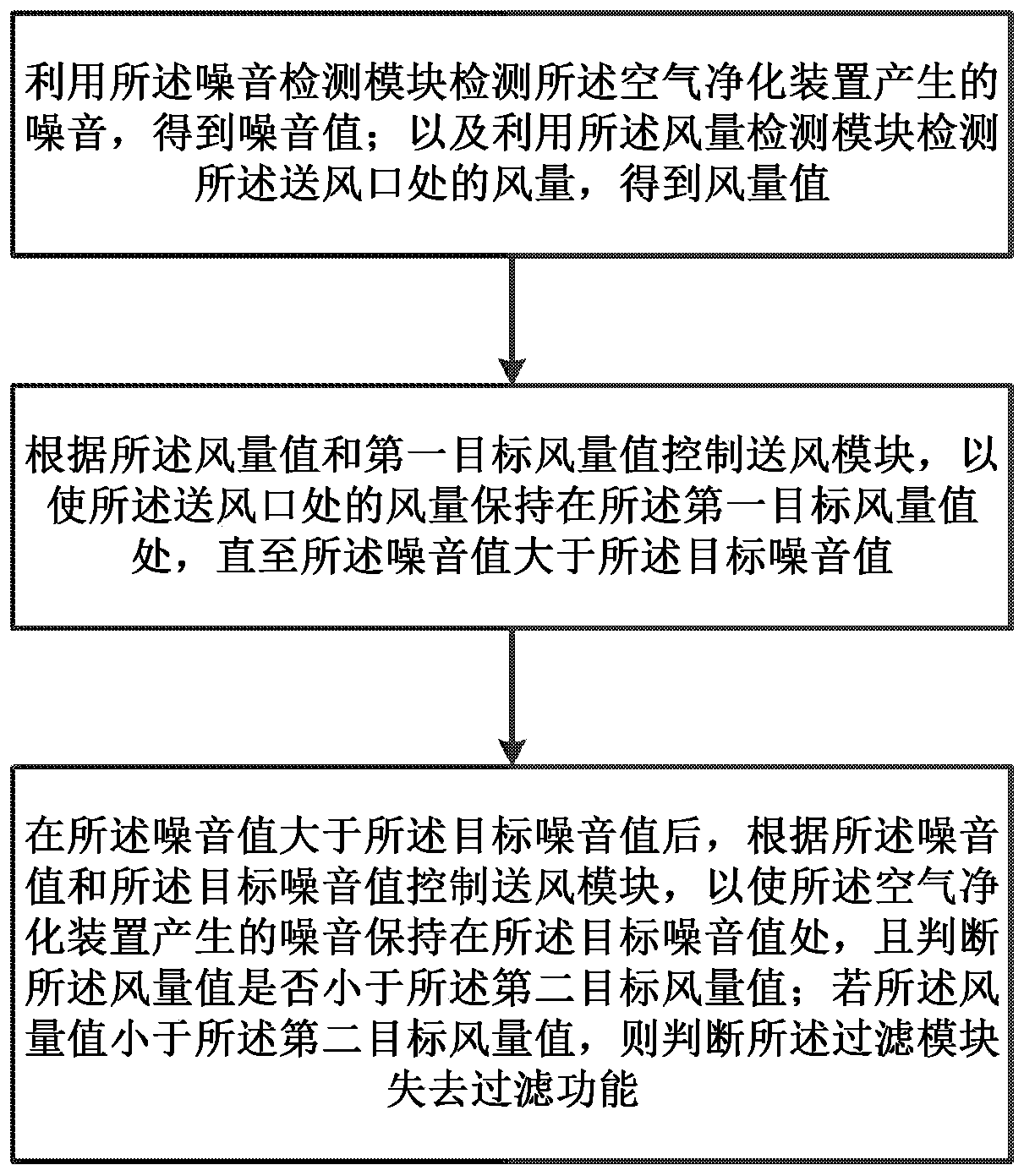

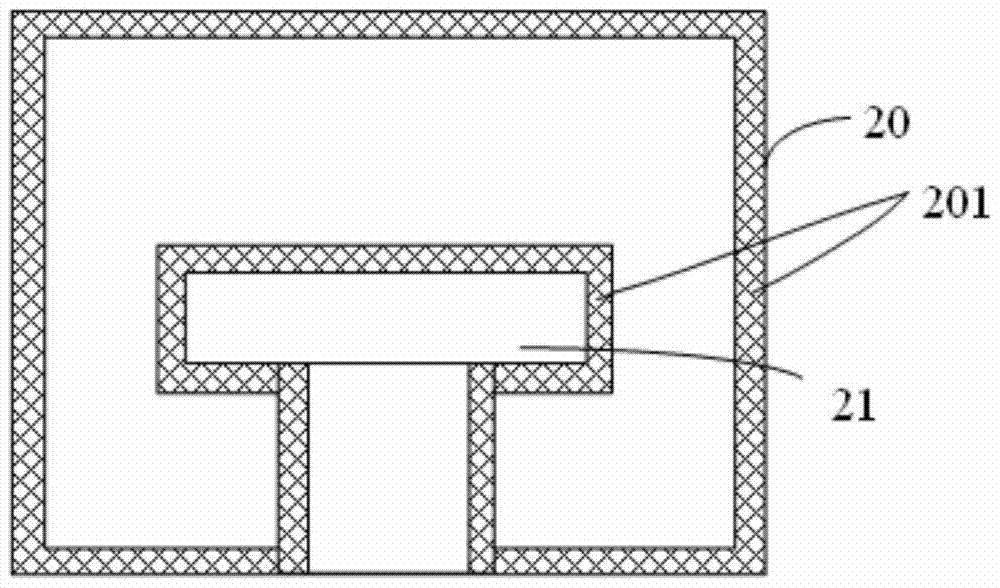

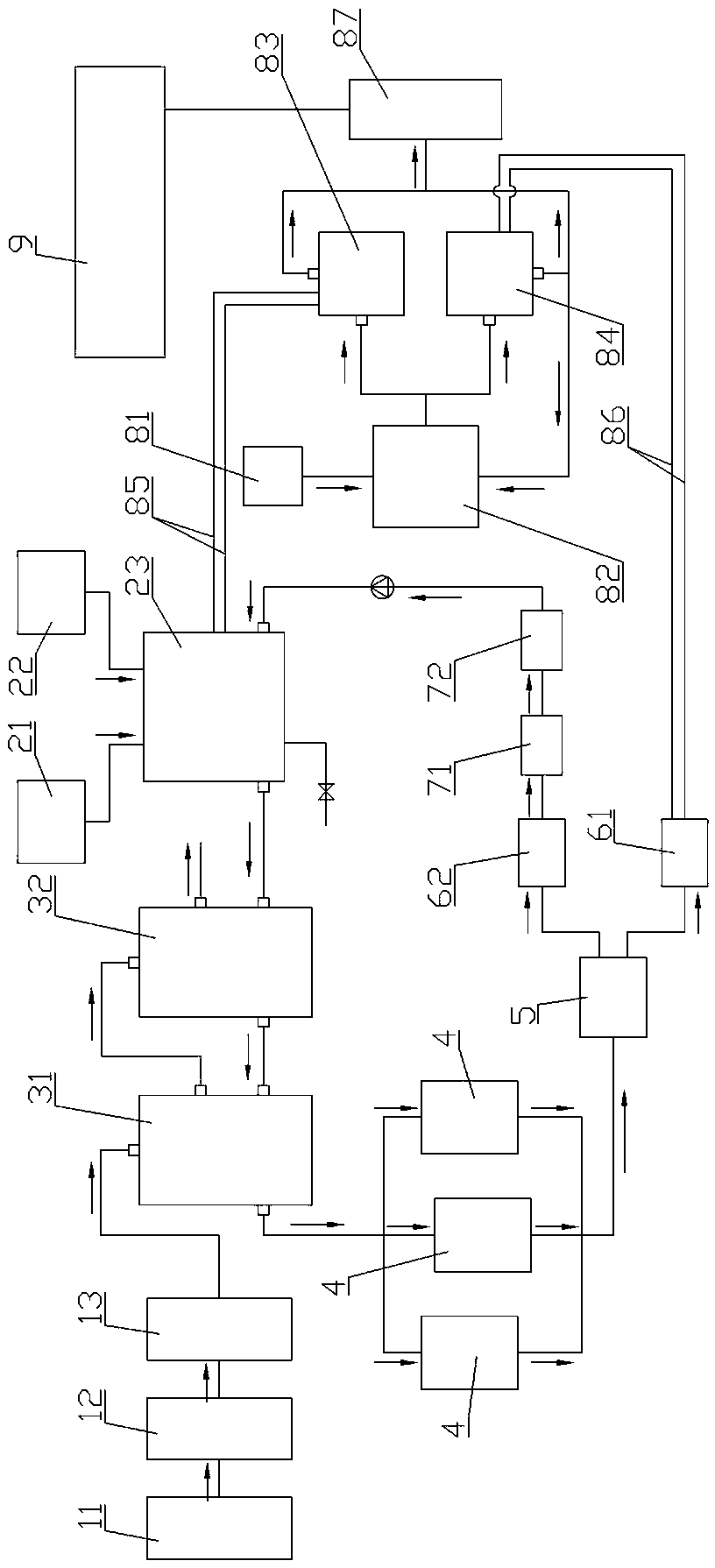

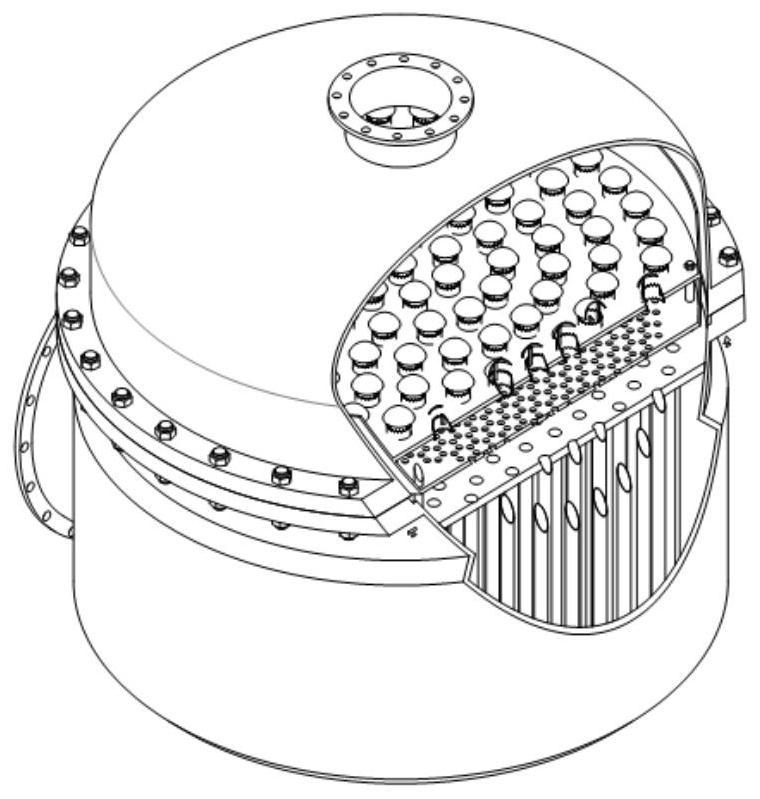

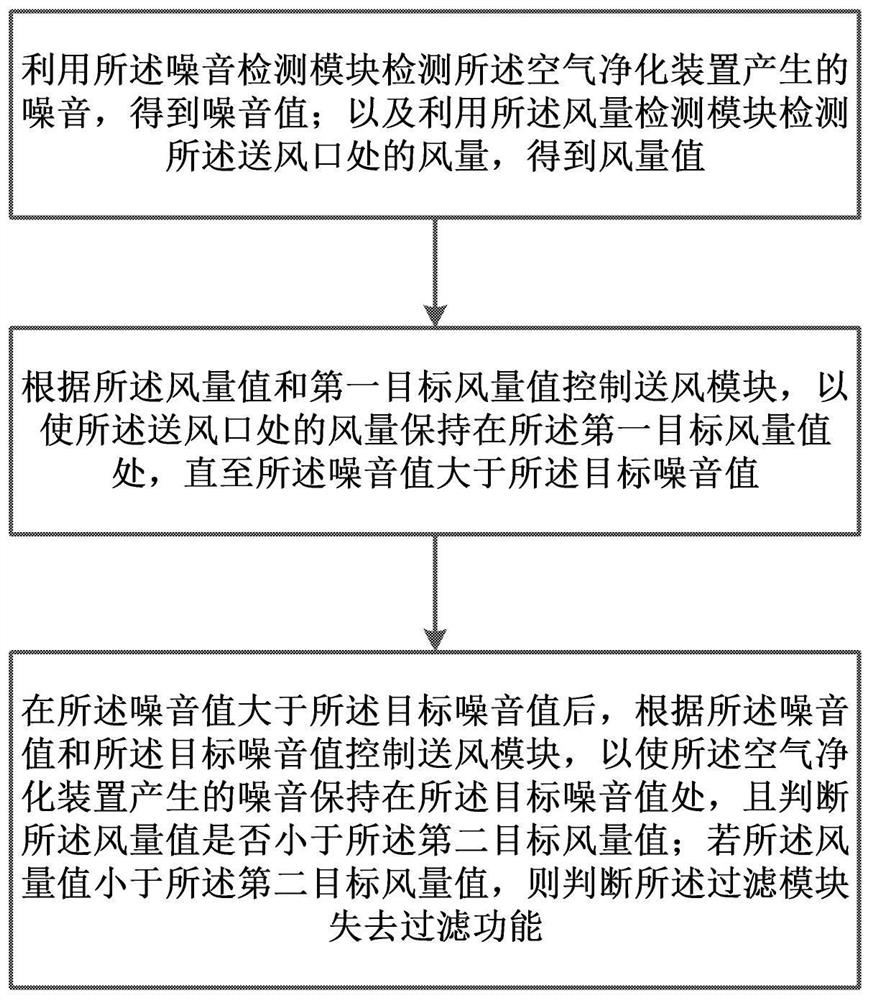

Air purifying device and control method thereof

ActiveCN109731419AConstant air volumeIncrease air volumeDispersed particle filtrationAir volumeWorking environment

The invention relates to an air purifying device and a control method thereof. The control method includes: acquiring an air volume value and a noise value; before the noise value is larger than a target noise value, controlling an air supply module according to the air volume value and a first target air volume value to keep the air volume at an air supply port at the first target air volume value; after the noise value is larger than a target noise value, controlling the air supply module according to the noise value and the target noise value to keep noise generated by the air purifying device at the target noise value, and judging whether the air volume value is smaller than a second target air volume value or not; if the air volume value is smaller than the second target air volume value, judging that a filter module loses a filtering function. The air supply volume of the air purifying device can be controlled according to the noise value, constant air supply volume of the air purifying device can be guaranteed as far as possible, noise increasing of the air purifying device is inhibited as far as possible under a high-noise condition while large air supply volume is realized, and accordingly a comfortable living and working environment can be provided for users.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Feeding pipe of reactor for continuous polymerization production of spandex

The invention relates to a feeding pipe of a reactor for continuous polymerization production of spandex. The pipe comprises a feeding pipe body (1), a mixed amine feeding pipe (2), a prepolymer feeding pipe (3), an end surface flange cover (4) and a manual doctor blade system (5), wherein the feeding pipe main body (1) comprises a main feeding pipe (1.3), a first flange (1.1) and a second flange(1.2); the mixed amine feeding pipe (2) comprises a mixed amine pipe (2.2) and a third flange (2.1), the third flange (2.1) is mounted at one end of the mixed amine pipe (2.2), and the mixed amine pipe (2.2) is arranged in the main feeding pipe (1.3); the prepolymer feeding pipe (3) comprises a prepolymer feeding branch pipe (3.1) and a fourth flange (3.2); the end surface flange cover (4) is connected with the outer end of the second flange (1.2); and the manual doctor blade system (5) comprises a handle (5.1), a first link rod (5.2), an eccentric crank (5.3), a second link rod (5.4) and a doctor blade (5.5). The feeding pipe of the reactor is reliable in performances, does not need to be cleaned regularly and can prevent the continuous generation of gumming phenomenon during the production.

Owner:JIANGYIN L V CHEM FIBER PROCESS TECH

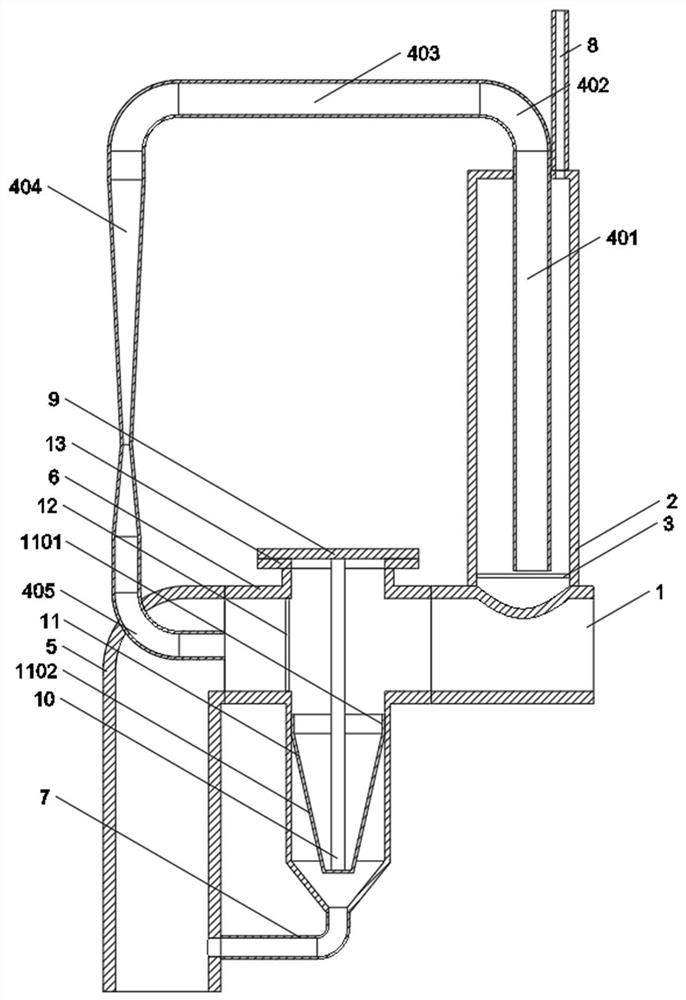

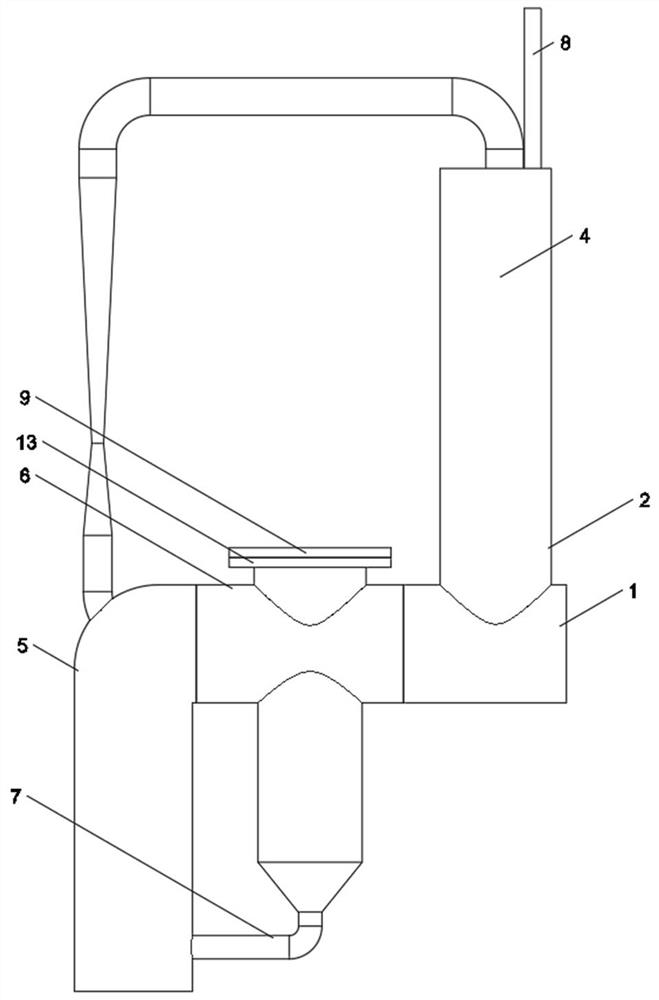

Unpowered self-cleaning rainwater filtering device

ActiveCN112973225ALarge filter areaIncrease water flow rateGeneral water supply conservationStationary filtering element filtersWater storageSiphon

The invention belongs to the technical field of rainwater filtering devices and particularly relates to an unpowered self-cleaning rainwater filtering device. The device comprises a water inlet three-way pipe; the water inlet three-way pipe is connected with a water inlet rainwater pipeline, a water storage pipe and a four-way pipe, an air inlet pipe is mounted at the top end of the water storage pipe, a filter screen is mounted at the bottom of the water storage pipe, and the inner side of the water storage pipe is connected with one end of a backwashing pipeline; the backwashing pipeline comprises a vertical pipe, an upper elbow, a transverse pipe, a Venturi pipe and a lower elbow, a drainage pipe connected with the other end of the backwashing pipeline is connected with a four-way pipe, the bottom side of the drainage pipe is connected with the four-way pipe through a seepage pipeline, the bottom end of the drainage pipe is connected with a water outlet rainwater pipeline, a flange blind plate connected with the top of the four-way pipe is connected with the top end of a connecting frame, and a filtering basket is installed at the bottom end of the connecting frame; the combined type design is low in cost and convenient to assemble, transportation, storage, popularization and use of the device are facilitated, water in the water storage pipe can be accelerated through the Venturi pipe under the siphon effect and sprayed out from the lower elbow, and unpowered backwashing of the filter plate is achieved.

Owner:浙江司邦齐环境科技有限公司

Chemical granulation processing method for quartz surface

A method for chemically and roughly treating a quartz surface overcomes the defects of the prior art in which the treatment to the quartz surface easily leads to damage and influences the size accuracy of the quartz product. The method is as below: at a normal temperature and a normal pressure, immersing a quartz product into a container filled with a treating fluid so as to undergo reaction after the surface of the quartz product is polished, taking out the quartz product after two-hour reaction, and immersing the quartz product into the treating fluid again so as to repeat the preceding reaction till the roughness Ra of the surface of the quartz product is equal to 1.5 micrometers to 4.5 micrometers after attachments on the surface of the quartz product is eliminated with deionized water. The treatment process has reasonable design, involves simple devices and is easy to be operated, and the obtained quartz product has uniform surface roughness which is free from the influence of the shape. During the participation in the CVD reaction, the crazing and the shedding of a deposited film on the quartz surface is effectively reduced so as to reduce the possibility of pollution to thereaction cavity, to remarkably improve the finished product rate and the production efficiency, and then further to prolong the service life of the quartz product, save time, reduce consumption and reduce production cost.

Owner:SHENYANG HANKE SEMICON MATERIALS

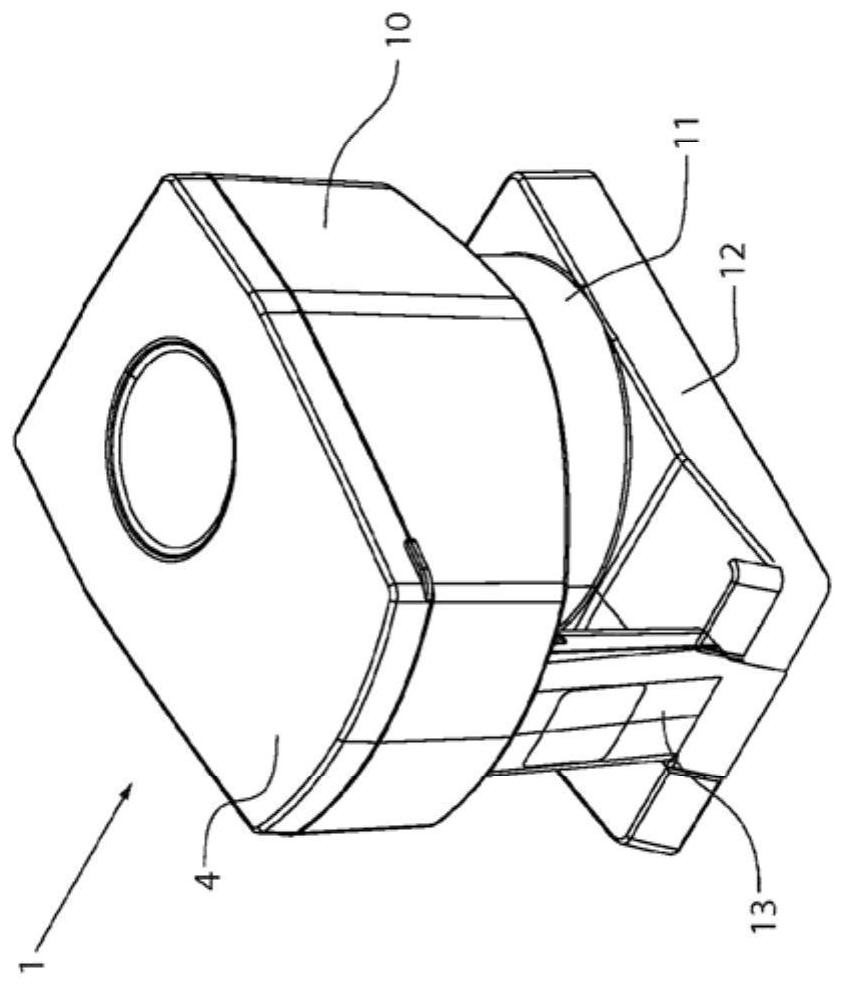

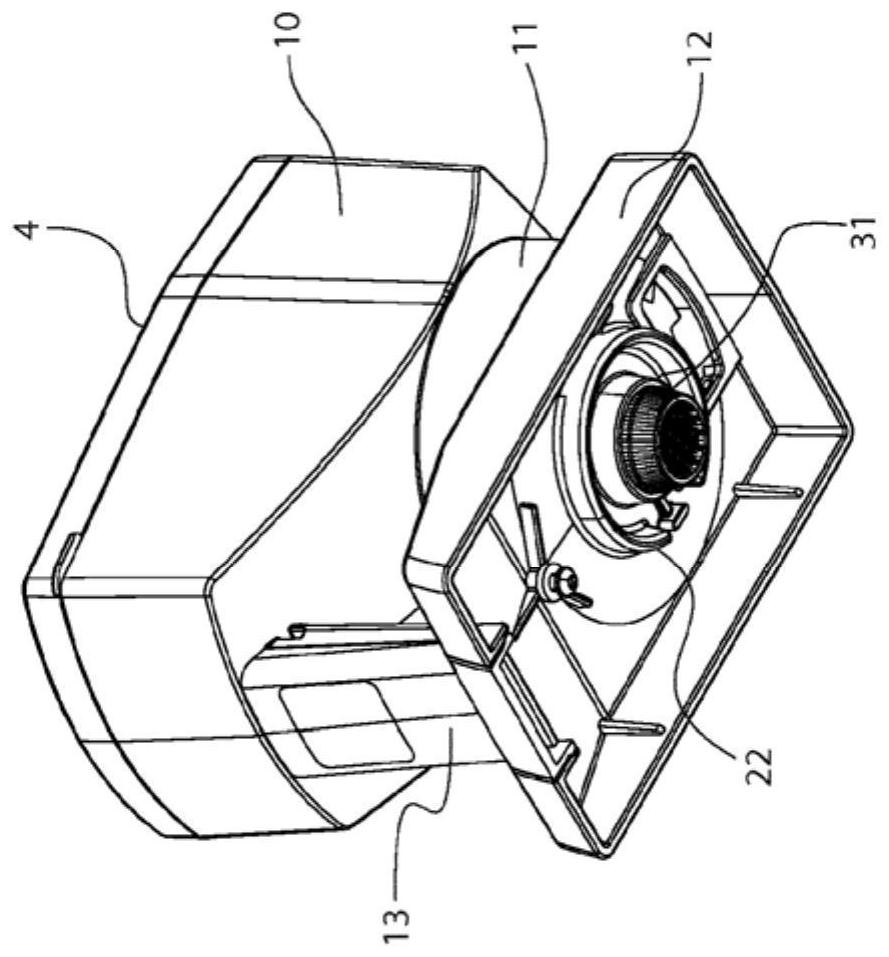

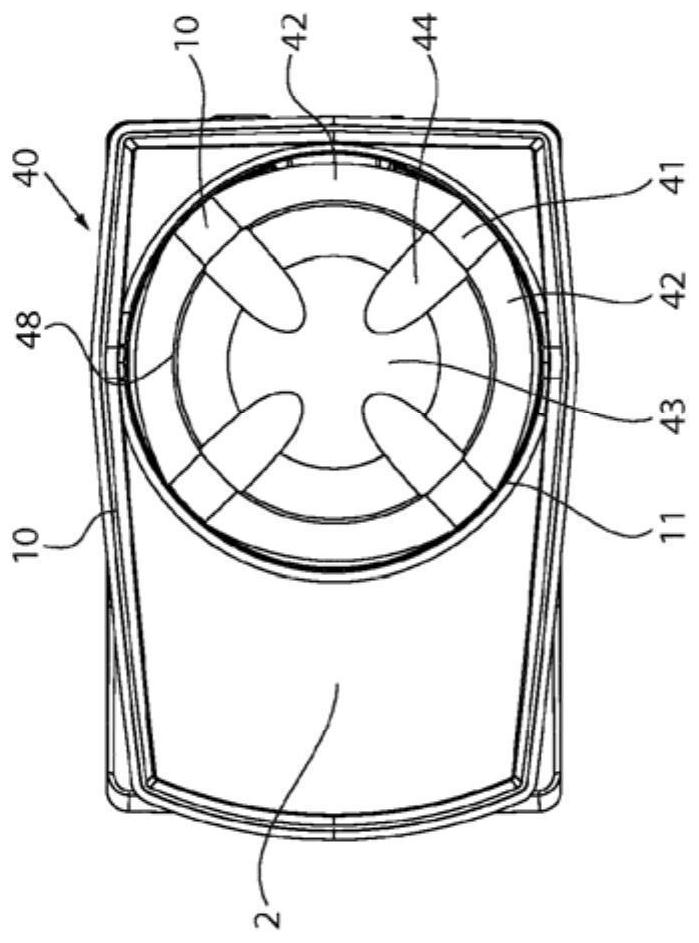

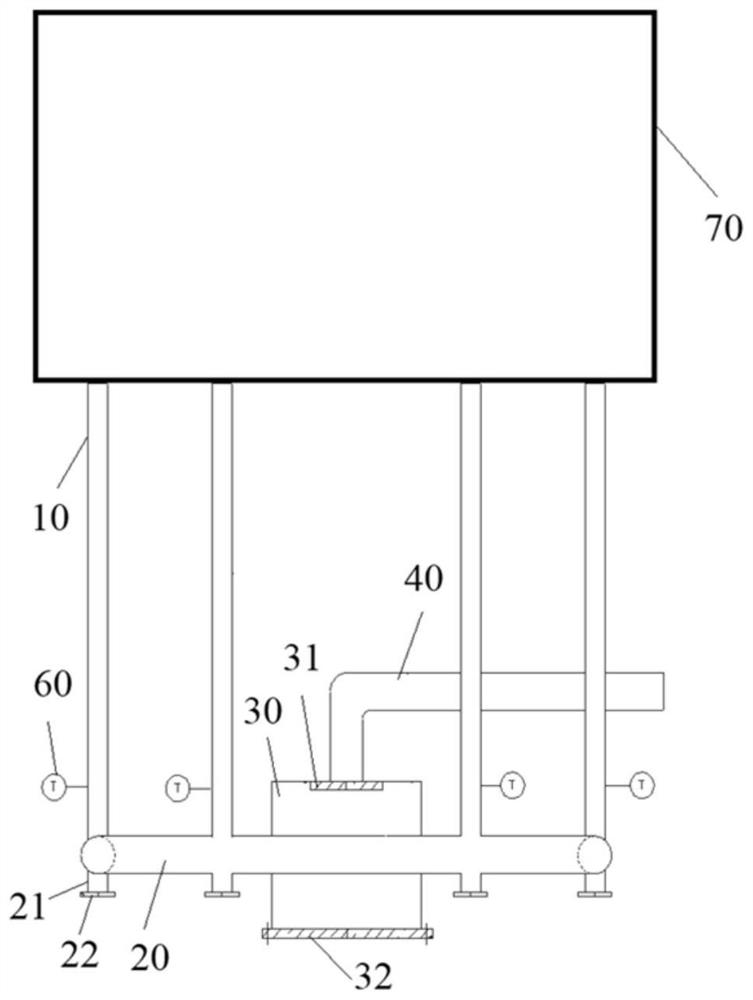

Storage container for storage and dispensing station for pharmaceuticals

PendingCN112638346AReduce accumulationReduce depositionSmall article dispensingCoin-freed apparatus detailsRotational axisProcess engineering

The invention relates to a storage container for storage and dispensing stations for pharmaceuticals. In known storage and dispensing stations, pharmaceutical dust formed by the individualization process produces increased friction between the individualization device and the wall of the storage and dispensing station. In order to prevent this, the storage and dispensing station comprises a housing (10), which surrounds a receiving chamber (2) and comprises a guide section (11), wherein an inner wall (3) of the guide section (11) defines a cylindrical guide chamber, and an individualization device (40), which is arranged in the guide section (11) of the housing (10) and has a central rotational axis (DA). The individualization device (40) has a main section (48) and a plurality of protrusions (42), each protrusion (42) having two end sections (45) and a central section (46), and a pharmaceutical channel (41) is formed between each two end sections (45) of adjacent protrusions. The central sections (46) of the protrusions (42) are retracted, and the end section (45) of each protrusion (42) rests against the wall (3) of the guide section (11).

Owner:BECTON DICKINSON ROWA GERMANY GMBH

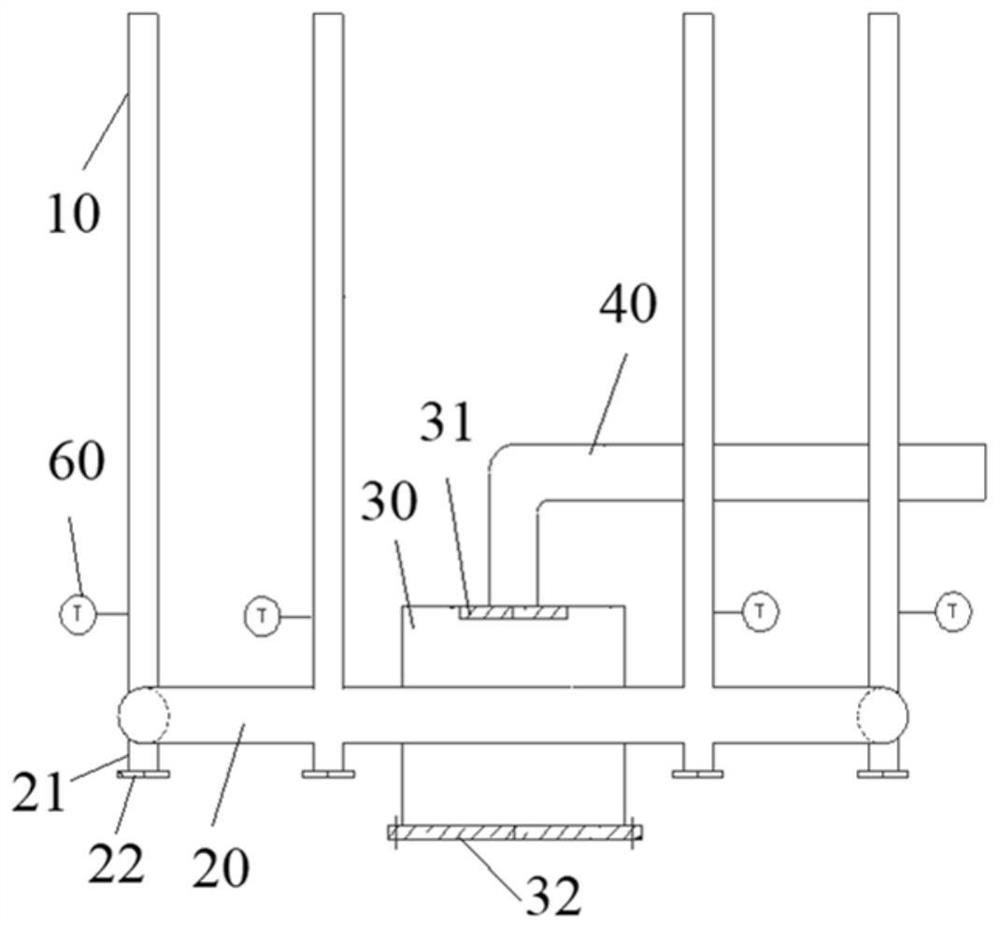

Air intake structure of window air conditioner

InactiveCN102062462BIncrease the areaReduce the average suctionAir-flow control membersForeign matterEddy current

The invention provides an air intake structure of a window air conditioner. The window air conditioner is divided into an indoor side and an outdoor side, wherein, an indoor air suction grille and an indoor air exhaust grille are arranged on a front panel at the indoor side; the front panel is internally equipped with an evaporator and an air supply fan; an outdoor air intake grille and an outdoor air exhaust grille are arranged on an enclosure at the outdoor side; the enclosure is internally equipped with a condenser and an eddy-current fan; an opening is arranged on a top plate of the enclosure, the inner side of the opening forms a ring cavity, the top of the ring cavity is opened, and a side plate grille is formed at the side plate inside the ring cavity; and an air intake plate detachably closes the opening on the top plate, and an air intake grille is formed at the position on the air intake plate corresponding to the open part of the ring cavity. The air intake structure of the window air conditioner has the beneficial effects of increasing the area of air intakes, reducing the average attractive force at the air intake grilles, lowering the possibility that fallen leaves are adsorbed, and ensuring normal operation of a fan; the ring cavity has the capability of storing adsorbed substances, thus effectively ensuring the cleanness in the enclosure and prolonging the cleaning time interval; and the structure is simple and beautiful and is rich in artistic sense, thus increasing the added value of the product, improving the product quality and prolonging the service life.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

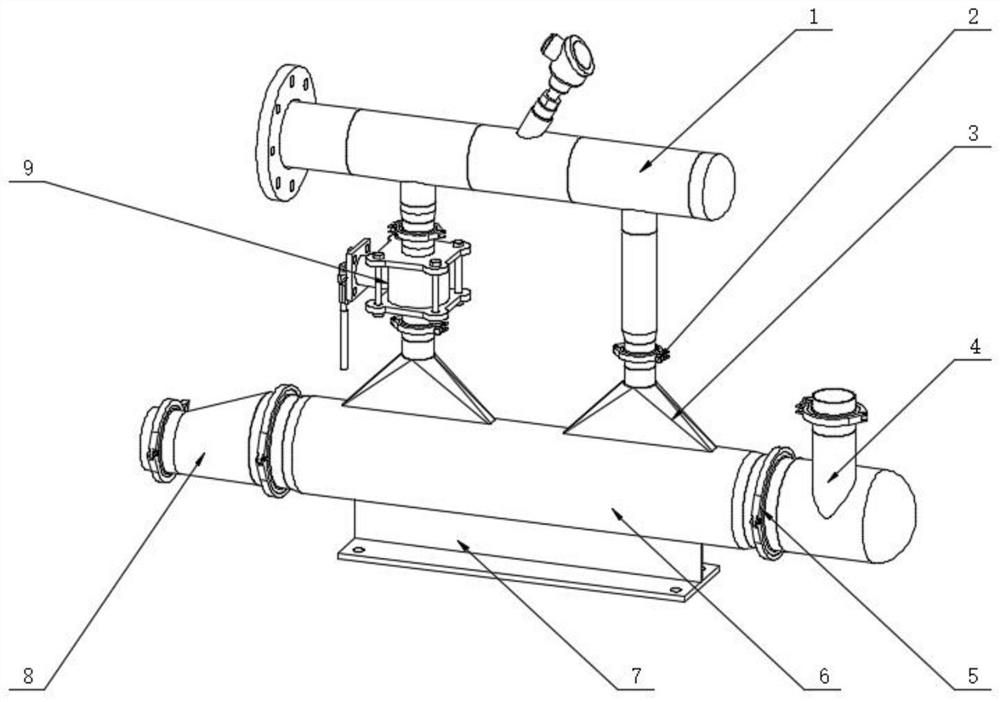

Tail gas emission structure and reduction furnace

PendingCN113307271AUniform and smooth dischargeGuarantee product qualitySilicon compoundsSlagEngineering

The invention discloses a tail gas emission structure and a reduction furnace. The tail gas emission structure comprises a plurality of tail gas branch pipes, the first end of each tail gas branch pipe communicates with an annular pipe, and the first ends of the multiple tail gas branch pipes are arranged in the circumferential direction of the annular pipe at intervals. The annular pipe communicates with a balance box. The first end of a tail gas mother pipe communicates with the balance box. The tail gas branch pipes communicate with exhaust holes in the bottom of a reduction furnace, gas in the reduction furnace enters the tail gas branch pipes through the exhaust holes, tail gas in the tail gas branch pipes enters the annular pipe, tail gas in different tail gas branch pipes can be balanced in the annular pipe, and the tail gas in the annular pipe enters the balance box to be balanced, so that the pressure of the gas is more uniform, and then gas in the balance box is exhausted through the tail gas mother pipe. The gas flow in each tail gas branch pipe is balanced through the annular pipe and the balance box, so that the silicon formation condition and the silicon slag cleaning frequency in the tail gas branch pipes are reduced, the tail gas emission is kept uniform and stable, and the pressure, the flow field and the temperature field in the reduction furnace are more stable.

Owner:新疆硅基新材料创新中心有限公司 +1

Baking soda preparation device and preparation method

ActiveCN109761248BReduce energy consumptionAdequate responseBicarbonate preparationThermodynamicsFlue gas

Baking soda preparation apparatus, including CO 2 Output device, Na 2 CO 3 Solution preparation device, carbonization device, crystallization barrel, first centrifuge, drying bed, mother liquor tank, mother liquor recovery device and heating device; a baking soda preparation method, applied to a baking soda preparation device, the steps are as follows: S01, respectively prepare CO 2 gas and Na 2 CO 3 solution; S02, flue gas heat exchange with the alkali-dissolving tank and drying bed; S03, flue gas recycling; S04, use the waste gas discharged from the comprehensive flue gas purification device to prepare CaCO 3 ; S05, preparation of CaCO 3 Finished product; the advantages of the present invention are: low wind pressure required for carbonization equipment; more complete internal reaction of carbonization equipment; recycling of raw materials; multiple utilization of internal heat; reuse of waste flue gas; basically no scarring inside the carbonization equipment.

Owner:谢精忠

A kind of rabbit breeding deodorizing liquid and its preparation method and use method

InactiveCN105285423BPromote reproductionPromote fermentationFood processingAnimal feeding stuffMeal powderMaterials preparation

The invention relates to a deodorizing liquid for rabbit culture. The deodorizing liquid is prepared from the following raw materials in parts by weight: 2 to 3 parts of biological zymocyte, 900 to 1100 parts of warm water with a temperature of 50 DEG C, 45 to 55 parts of brown sugar, 90 to 110 parts of corn flour, 45 to 55 parts of cooked soybean meal powder, and 45 to 55 parts of cooked rapeseed meal powder. The manufacturing method comprises steps of material preparation, breeding, mixing, and fermentation. The application method comprises the following steps: (1) weighing a certain amount of prepared deodorizing liquid, diluting the deodorizing liquid with water according to a ratio of deodorizing liquid to water of 1:10, then spraying the diluted deodorizing liquid into rabbit feed, evenly stirring, and feeding the rabbits by the feed; (2) weighing a certain amount of prepared deodorizing liquid, then diluting the deodorizing liquid with water according to a ratio of deodorizing liquid to water of 1:25, and then spraying the diluted deodorizing liquid into rabbit manure which is excreted by the rabbits in the step (1). The invention aims to provide a deodorizing liquid for rabbit culture, a preparation method and application method thereof. The rabbit manure is deodorized through a microbial fermentation method, mosquitoes will not generate around the processed rabbit manure, the rabbit manure can be cleaned for every 3-5 months, the labor resource and material resource are both reduced, and at the same time the manure is effectively used and can be used to produce farm manure.

Owner:HUNAN HUILONG RABBIT DEV

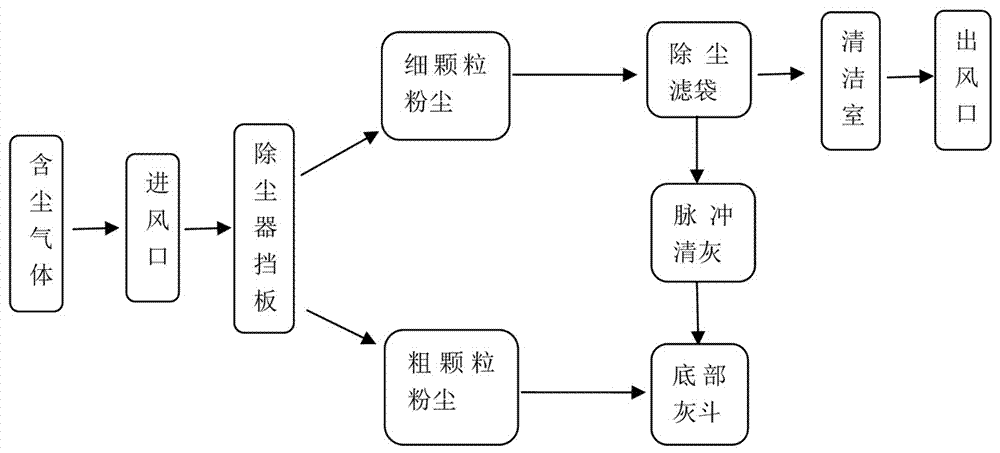

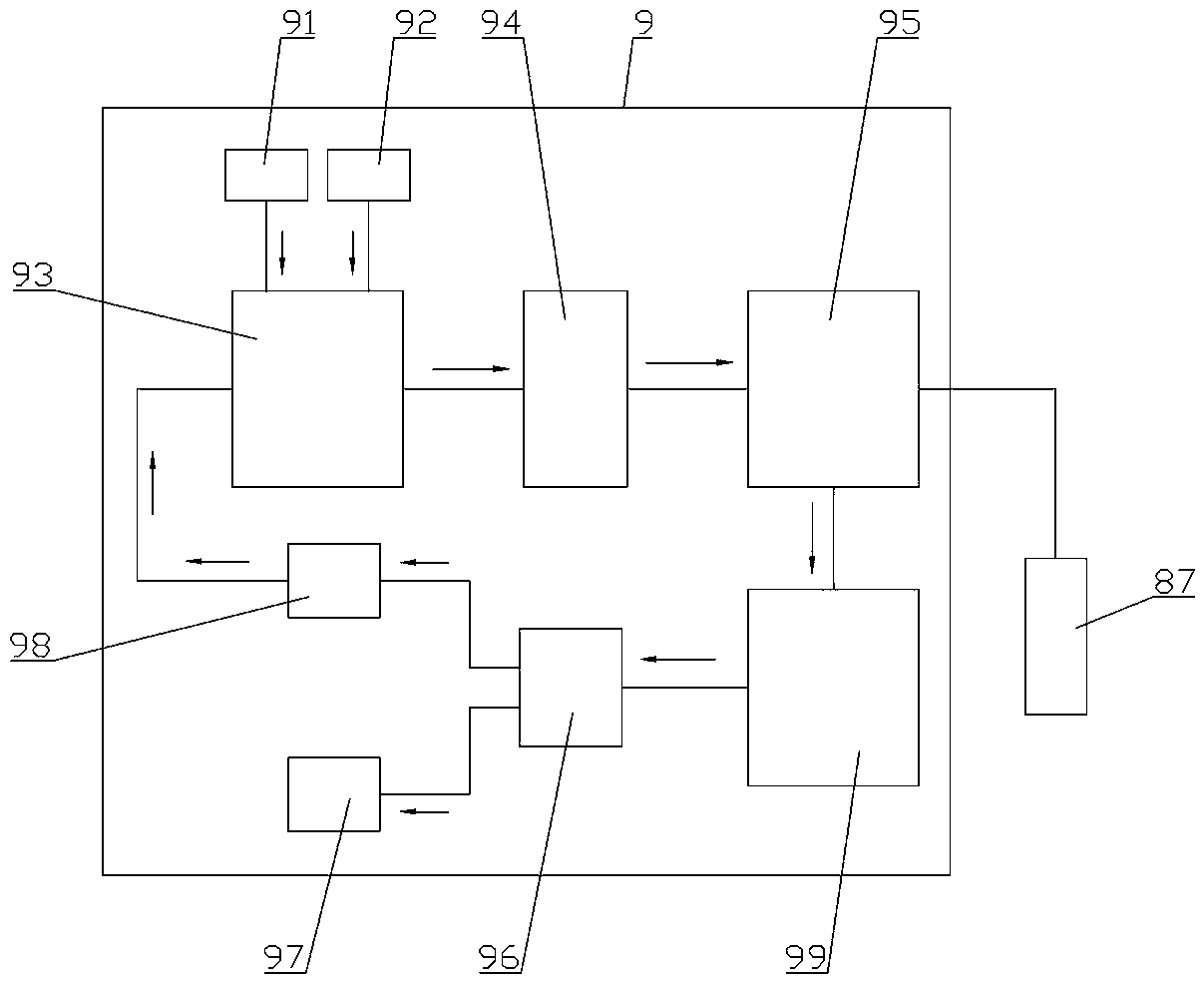

Bag deduster online pulse blowing ash removal control method

InactiveCN103084013AExtend cleaning intervalsReduce dosageDispersed particle filtrationEngineeringTime sequence

The invention discloses a bag deduster online pulse blowing ash removal control method. An ash removal control time sequence starts from the first pulse valve of a first room to the first pulse valve of a second room, then to the first pulse valve of a third room until to the first pulse valve of a last room, then to the second pulse valve of the first room, ... until to the second pulse valve of the last room, then to the third pulse valve of the first room, ... until to the third pulse valve of the last room, and then to the last pulse valve of the first room, ... until to the last pulse valve of the last room. The method which allows the resistance fluctuation among all the above rooms to be small during ash removal is in favor of the uniform airflow distribution among all the rooms, substantially prolongs the ash removal time interval of the deduster ash removal pulse valves, and reduces the application amount of compressed air for the ash removal.

Owner:JIEHUA HLDG

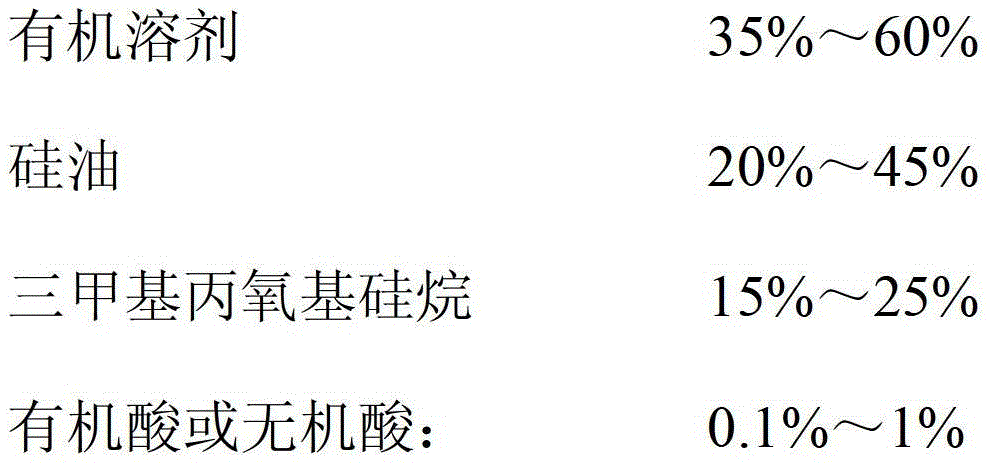

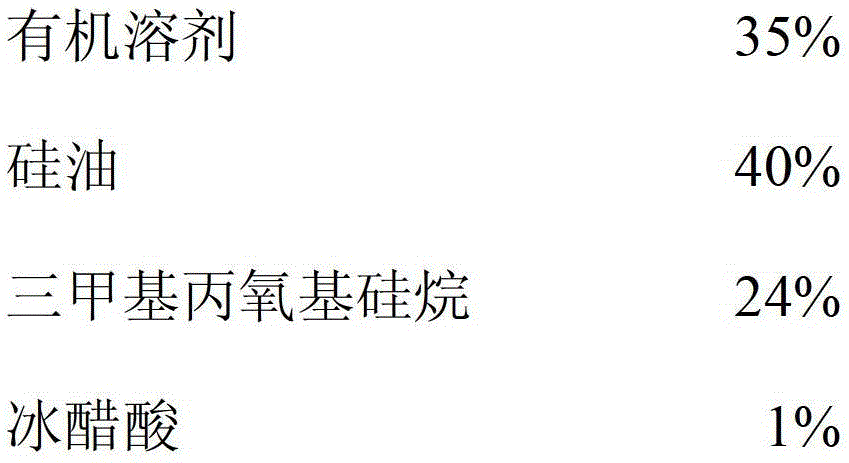

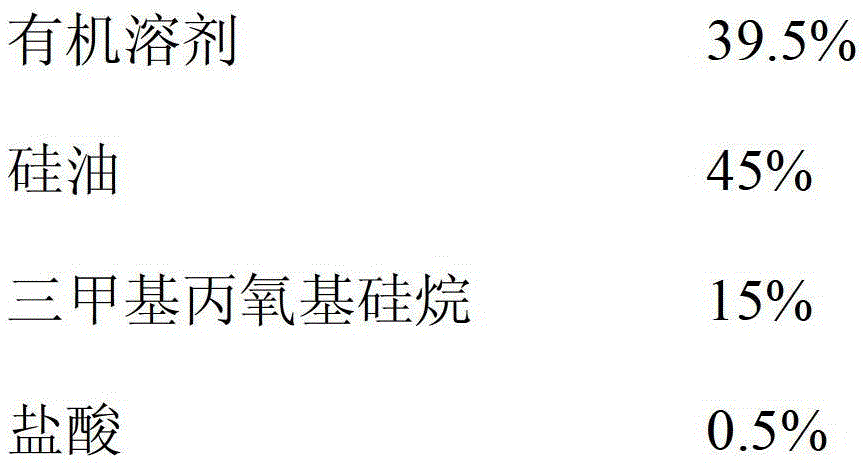

An easy-to-clean hydrophobic coating

The invention relates to an easy-to-clean hydrophobic coating which is characterized by comprising the following components in weight percentage: 35-60 percent of organic solvents, 20-45 percent of silicon oil, 15-25 percent of trimethyl-n-propoxysilane, and 0.1-1 percent of organic acid or inorganic acid. The easy-to-clean hydrophobic coating has the advantages of environmental protection and hydrophobic property, after the easy-to-clean hydrophobic coating is coated on the glass surface, the common glass has the easy-to-clean hydrophobic function, and the easy-to-clean hydrophobic coating has the antibacterial and anti-mildew effects, is longer in service life, and resistant to yellowing and ultraviolet rays, provides a convenience for life of people and saves cost.

Owner:FOSHAN DABBL SANITARY WARE

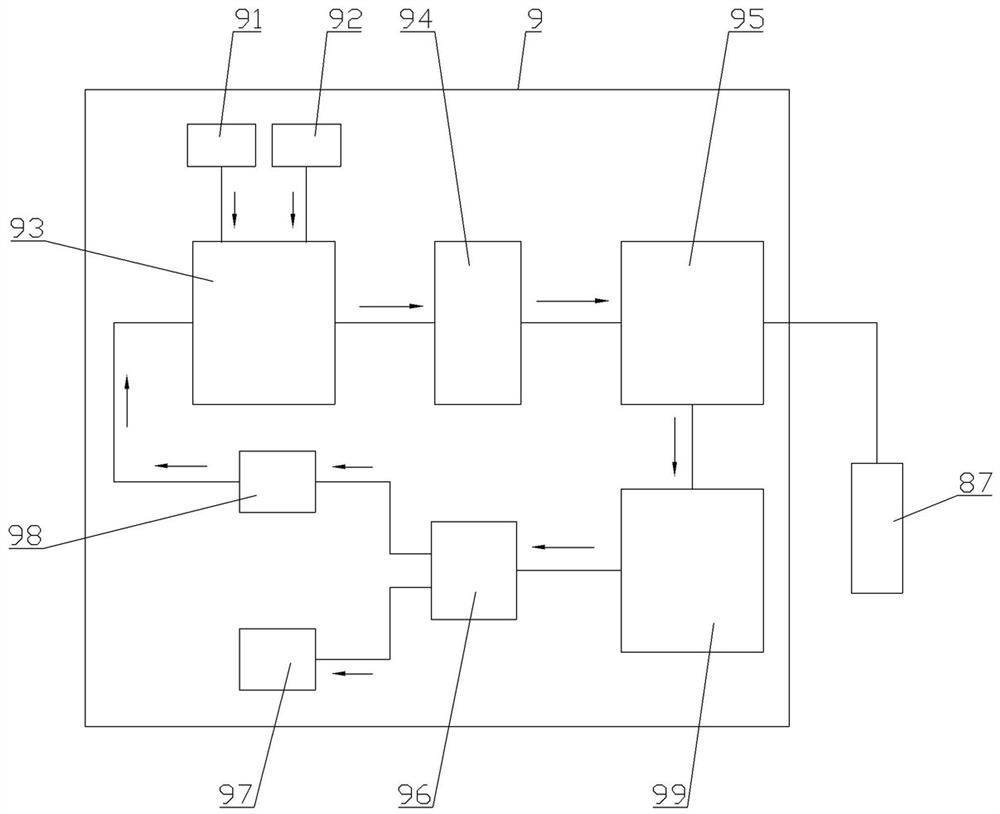

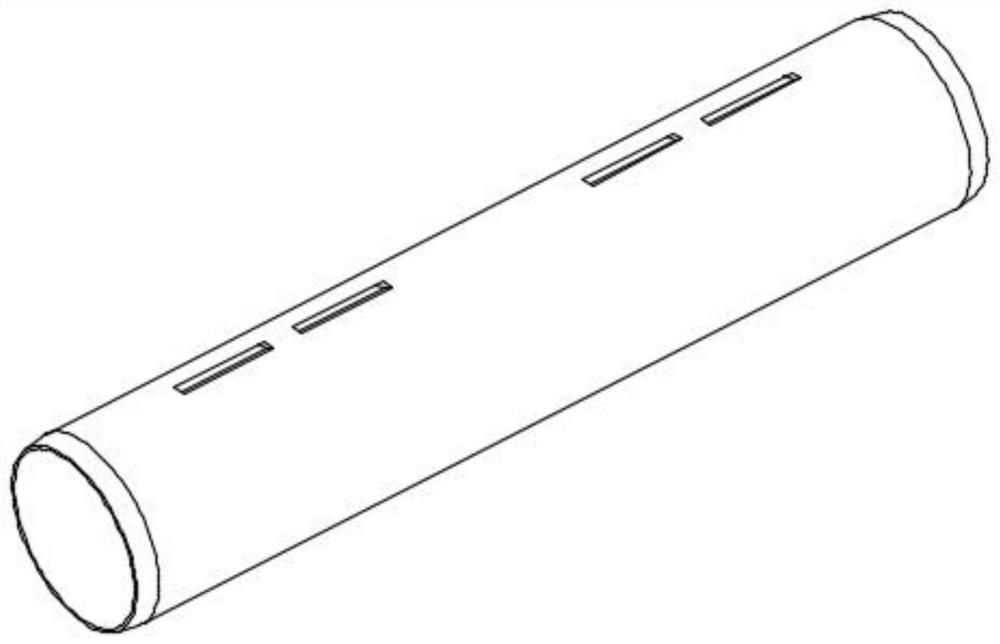

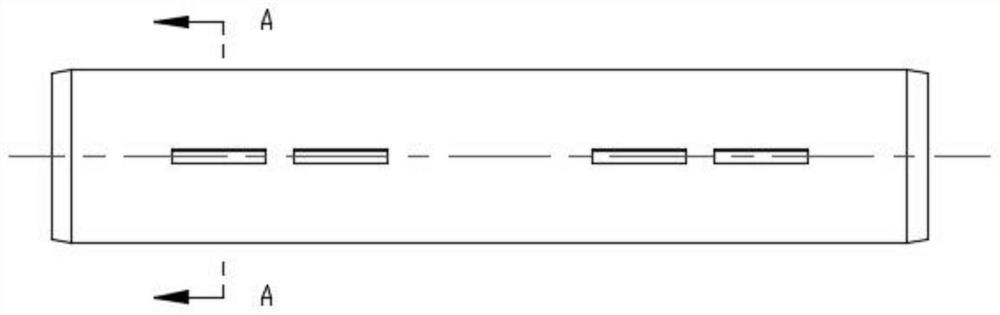

Vortex type vapor-liquid direct mixing sterilization device

PendingCN111728027ASolve the large consumptionSolve easy foulingMilk preservationThermodynamicsEngineering

The invention provides a vortex type vapor-liquid direct mixing sterilization device, and belongs to the field of milk production mechanical equipment. The problems that an existing sterilizer is longin heating time, large in steam consumption and prone to scaling are solved. The vortex type vapor-liquid direct mixing sterilization device comprises a steam inlet pipe, a reducer union, a feeding pipe, a vapor-liquid mixing chamber and a discharging pipe, wherein an inlet of the steam inlet pipe is connected with a steam pipeline; the steam inlet pipe is provided with a plurality of steam outlets; each steam outlet is connected with the closing end of the reducer union; the vapor-liquid mixing chamber is provided with a steam inlet; the steam inlet is a long-strip hole in the tangential direction; the flaring end of the reducer union is connected with the steam inlet formed in the vapor-liquid mixing chamber; one end of the vapor-liquid mixing chamber is connected with the feeding pipe,and the other end of the vapor-liquid mixing chamber is connected with the discharging pipe; and an inlet of the feeding pipe is formed in the tangential direction. The vortex type vapor-liquid direct mixing sterilization device is mainly used for sterilizing materials.

Owner:HEILONGJIANG REALGOAL TECHNOLOGY CO LTD +1

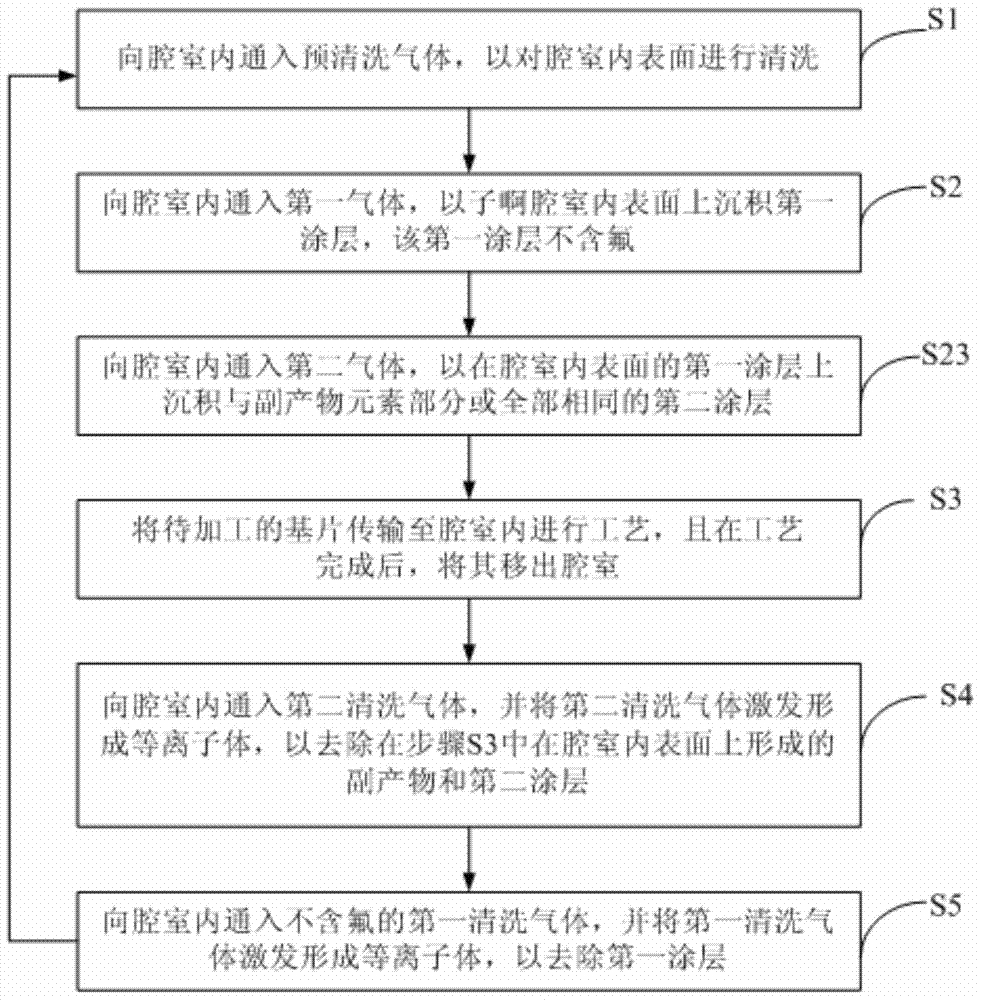

A method for controlling the environment of a chamber

ActiveCN105448634BExtend cleaning intervalsAchieve consistencyElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringFluoride

The invention provides a chamber environment control method comprising the following steps: step S1, feeding a pre-cleaning gas into a chamber to clean the inner surface of the chamber; step S2, feeding a first gas into the chamber to deposit a first coating on the inner surface of the chamber, wherein the first coating does not contain fluorine; step S3, transmitting a to-be-processed substrate into the chamber for a process, and removing the to-be-processed substrate out of the chamber after the process is completed; step S4, feeding a second cleaning gas into the chamber, and exciting the second cleaning gas to form a plasma so as to remove byproducts formed on the inner surface of the chamber in step S3; and step S5, feeding a first cleaning gas containing no fluoride into the chamber, and exciting the first cleaning gas to form a plasma so as to remove the first coating and restore the chamber environment. The method can avoid the corrosion of fluoride to the inner surface of the chamber and fundamentally eliminate the fluorine memory effect of the chamber, and therefore, the chamber environment is consistent for each process.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

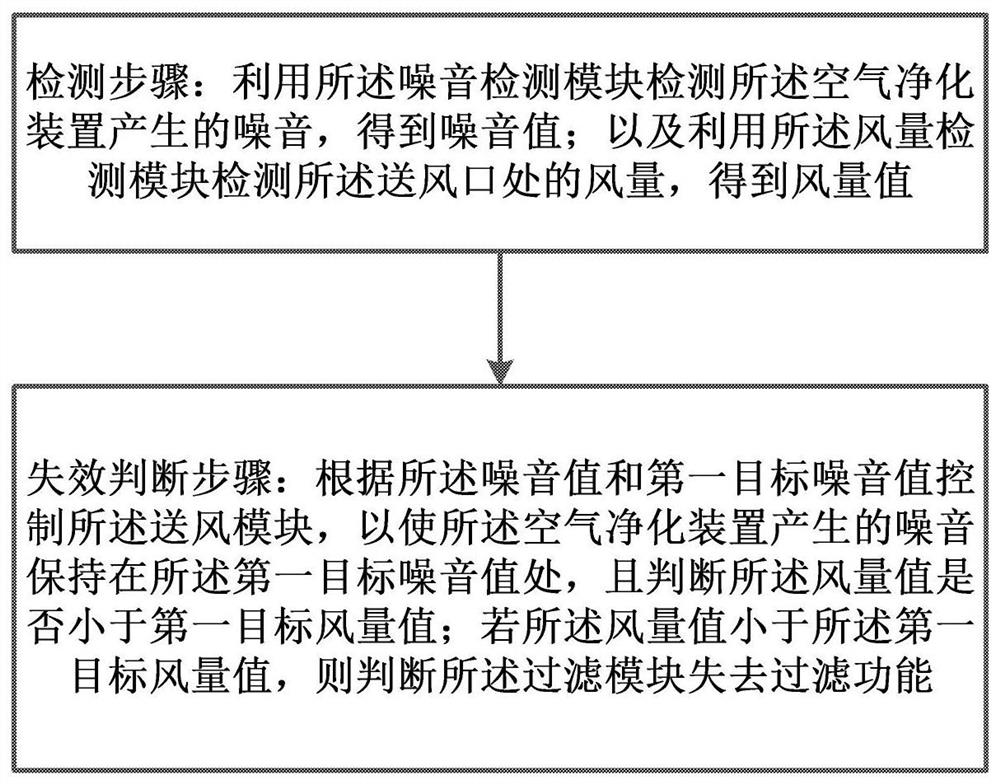

Air purification device can determine filter module failure control method and air purification device

ActiveCN109731402BEasy to controlPrompt is accurateDispersed particle filtrationAir volumeAir purifiers

The invention relates to a control method to allow an air purifier to judge failure of a filter module and the air purifier. Particularly, the control method includes the steps of detecting, to be specific, detecting noise generated by the air purifier through a noise detection module to obtain a noise value; detecting air quantity at an air supply port through an air quantity detection module toobtain an air quantity; judging failure, to be specific, controlling an air supply module according to the noise value and a first target noise value so that the noise generated by the air purifier ismaintained to the first target noise value, and judging whether the air quantity is less than a first target air quantity; if yes, determining that the filter module loses the filtering function. Whether the filter module fails can be determined according to the noise value and the air quantity so as to remind a user of changing or washing the filter module; controlling is convenient; reminding is accurate.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Sodium bicarbonate preparation device and preparation method

ActiveCN109761248AReduce energy consumptionAdequate responseBicarbonate preparationSodium bicarbonateCarbonization

The invention relates to a sodium bicarbonate preparation device, which comprises a CO2 producing device, a Na2CO3 solution preparation device, a carbonization device, a crystallization barrel, a first centrifugal machine, a drying bed, a mother liquid tank, a mother liquid recovery device and a heat supply device. A sodium bicarbonate preparation method is applied to the sodium bicarbonate preparation device, and comprises the following steps that S01, CO2 gas and Na2CO3 solution are respectively prepared; S02, smoke gas heat respectively performs heat exchange with an alkaline dissolving tank and a drying bed; S03, smoke gas is recovered and utilized; S04, waste gas exhausted by a smoke gas comprehensive purification device is used for preparing CaCO3; S05, a CaCO3 finished product is prepared. The sodium bicarbonate preparation device and the sodium bicarbonate preparation method have the advantages that the wind pressure required by carbonization equipment is low; the reaction inside the carbonization equipment is full and comprehensive; raw materials are cyclically utilized; inside heat is multiply utilized; waste smoke gas is reutilized; no scaring phenomenon basically existsinside the carbonization equipment.

Owner:谢精忠

A non-powered self-cleaning rainwater filter device

ActiveCN112973225BLarge filter areaIncrease water flow rateGeneral water supply conservationStationary filtering element filtersTube drainageEnvironmental engineering

The invention belongs to the technical field of rainwater filtering devices, and in particular relates to a non-powered self-cleaning rainwater filtering device, which includes a water inlet three-way pipe connected to a water inlet rainwater pipeline, a water storage pipe and a four-way pipe for water storage An inlet pipe is installed on the top of the pipe, a filter is installed on the bottom, and one end of the backwash pipeline is connected to the inside. The backwash pipeline includes a vertical pipe, an upper elbow, a horizontal pipe, a Venturi tube, and a lower elbow, and the other end of the backwash pipeline The connected drain pipe is connected with a four-way pipe, the bottom side of the drain pipe is connected to the four-way pipe through the seepage pipeline, the bottom of the drain pipe is connected to the outlet rainwater pipeline, the flange blind plate connected to the top of the four-way pipe is connected to the top of the connecting frame, and the bottom of the connecting frame A filter basket is installed at the end of the cross pipe, and a filter plate is installed at the end of the four-way pipe facing the drain pipe. The combined design is low in cost and easy to assemble, which is conducive to the transportation, storage and popularization of the device. The tube speeds up and sprays out from the lower elbow to realize non-powered backwashing of the filter plate.

Owner:浙江司邦齐环境科技有限公司

Dust collection device for vacuum drier

ActiveCN102284206BExtend cleaning intervalsIncrease productivityStationary filtering element filtersEngineeringUltimate tensile strength

The invention relates to a dust collection device for a vacuum drier. The dust collection device comprises a dust collection barrel and a vacuum pump, and is characterized in that: the dust collection barrel comprises a barrel body and an air inlet pipe; a vacuumizing hole is formed on the side wall of the barrel body; a drain outlet is formed at the bottom of the barrel body; the air inlet pipe is inserted into the barrel body; a dust collector is arranged between the dust collection barrel and the vacuum pump; a dust inlet of the dust collector is connected with the vacuumizing hole of the dust collection barrel; and a vacuumizing interface of the dust collector is connected with the vacuum pump. The dust collection device has the advantages that: when the vacuum drier is used for drying, dust is separated from water completely, the dust collection device is not needed to be cleaned frequently, and the production efficiency is improved while the labor intensity of workers is reduced.

Owner:JIANGYIN CHEM MASCH CO LTD

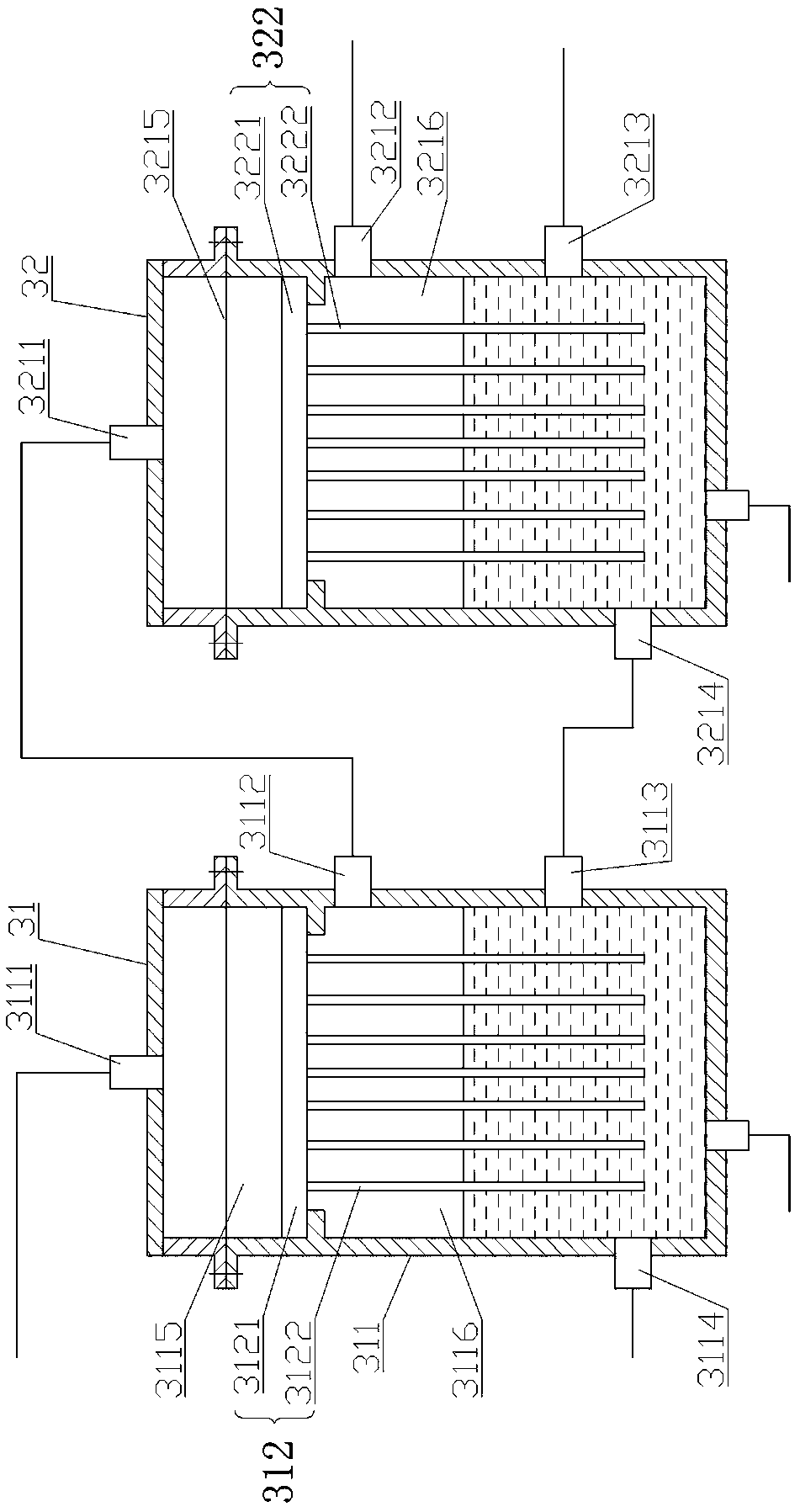

A tube-type falling film evaporator, a concentration device and its use method and process

ActiveCN111359240BNot easy to gelatinize and hang on the wallSufficient heat exchangeMultiple-effect evaporationWater vaporEconomic benefits

The invention discloses a tube-type falling film evaporator, a concentrating device and its use method and process; it includes a first evaporation unit, a second evaporation unit, a third evaporation unit and a fourth evaporation unit; the first evaporation unit consists of a wet The secondary steam generated by the protein drying process is used as a heat source, the second evaporation unit uses the secondary steam generated by the first evaporation unit as a heat source, and the third evaporation unit adopts the MVR evaporation process, and the secondary steam generated by it is After being pressurized and heated by a mechanical compressor, it is used as the heat source of the third evaporation unit, and the fourth evaporation unit uses water vapor as the heat source; the evaporators of the first evaporation unit, the second evaporation unit and the third evaporation unit are all tube-type Falling film evaporator, the present invention can improve the equipment utilization rate, thereby greatly reducing the production cost of the enterprise, and bringing greater economic benefits to the enterprise.

Owner:SHANDONG KAISTAR MASCH MFG CO LTD

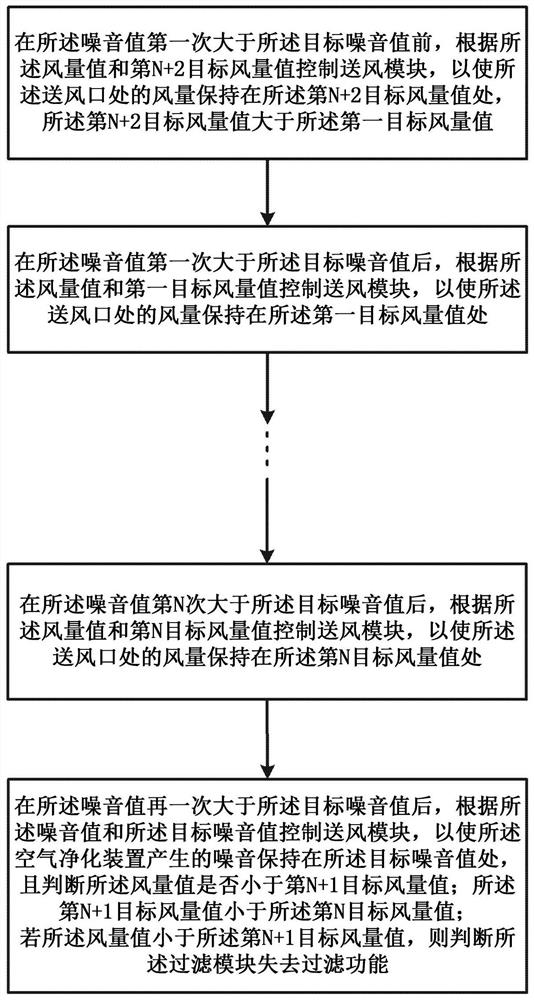

Noise-based control method for air purification device and air purification device

ActiveCN109718613BReduce noiseConstant air volumeDispersed particle filtrationNoise controlAir volume

The invention relates to a noise-based control method for an air purification device and an air purification device. Specifically, the control method includes: using the noise detection module to detect the noise generated by the air purification device to obtain the noise value; and using the air volume detection module to detect the air volume at the air outlet to obtain the air volume value; after the noise value is greater than the target noise value for the Nth time , control the air supply module according to the air volume value and the Nth target air volume value, so that the air volume at the air supply port remains at the Nth target air volume value, N is a natural number greater than or equal to 1; and when N is greater than 1, the Nth target The air volume value is less than the N‑1th target air volume value. The air supply volume of the air purification device can be controlled according to the noise value, which can ensure a constant air supply volume of the air purification device as much as possible, and can make the noise generated by the air purification device lower, providing users with a comfortable living and working environment.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

A control method of an air purification device and an air purification device

ActiveCN109731419BConstant air volumeIncrease air volumeDispersed particle filtrationAir volumeWorking environment

The invention relates to an air purifying device and a control method thereof. The control method includes: acquiring an air volume value and a noise value; before the noise value is larger than a target noise value, controlling an air supply module according to the air volume value and a first target air volume value to keep the air volume at an air supply port at the first target air volume value; after the noise value is larger than a target noise value, controlling the air supply module according to the noise value and the target noise value to keep noise generated by the air purifying device at the target noise value, and judging whether the air volume value is smaller than a second target air volume value or not; if the air volume value is smaller than the second target air volume value, judging that a filter module loses a filtering function. The air supply volume of the air purifying device can be controlled according to the noise value, constant air supply volume of the air purifying device can be guaranteed as far as possible, noise increasing of the air purifying device is inhibited as far as possible under a high-noise condition while large air supply volume is realized, and accordingly a comfortable living and working environment can be provided for users.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com