Air purification device can determine filter module failure control method and air purification device

A technology of air purification device and control method, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle filtration, etc., which can solve the problems of air purification device air volume reduction, consumable resistance increase, and non-consideration, etc., to prolong the cleaning time Interval, prolong service life, prompt accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

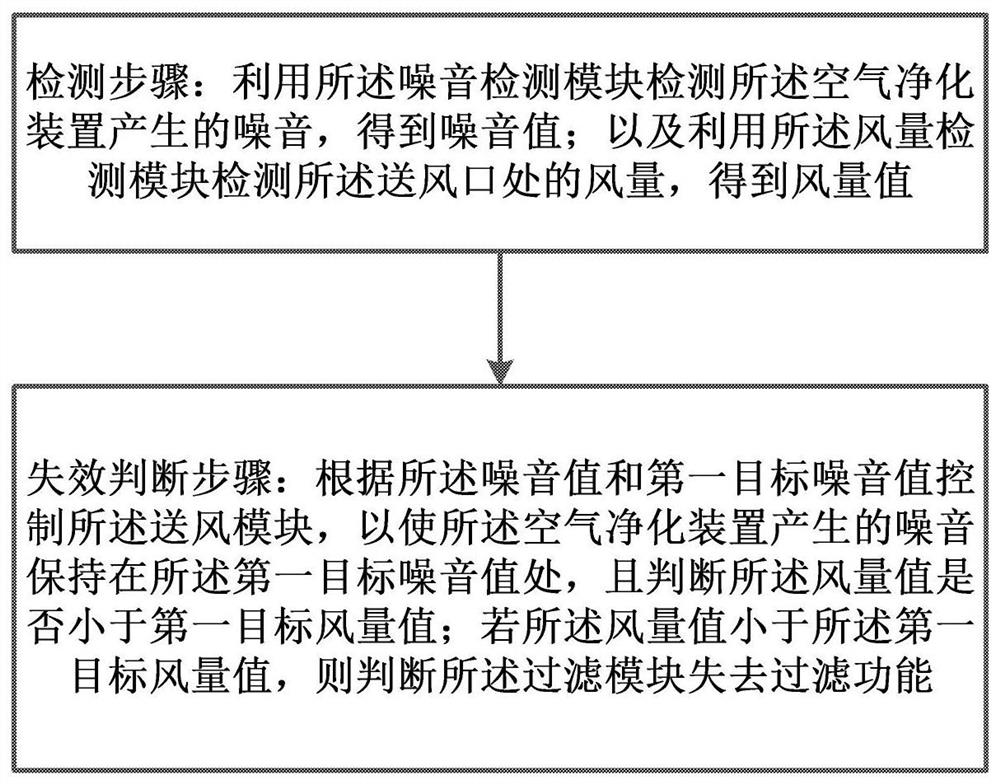

[0023] figure 1 It is a schematic flow chart of a control method for an air purification device that can determine the failure of a filter module according to an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a control method for an air purification device that can determine the failure of the filter module. The air cleaning device may include an air supply port, a filter module, an air supply module, an air volume detection module and a noise detection module. The air supply module is configured to encourage the air to flow to the air supply port after being filtered by the filter module. The air volume detection module is configured to detect the air volume at the air outlet. The noise detection module is configured to detect noise generated by the air cleaning device. The filter module is preferably a filter screen, and the air supply module is preferably a fan. Among them, the control method for the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com