Oil-fog separation blade, oil-fog separation device and application method of oil-fog separation device

An oil mist separation and blade separation technology, applied in the fields of oil mist separation blades, separation devices, and oil mist separation devices, can solve the problems of increased maintenance costs, difficult to clean grease-like dirt, and poor air suction, and achieves oil mist separation. The effect of high separation efficiency, flexible use and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

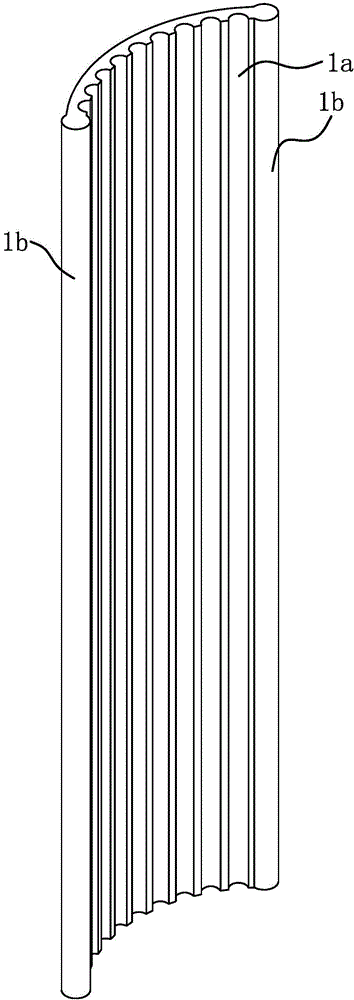

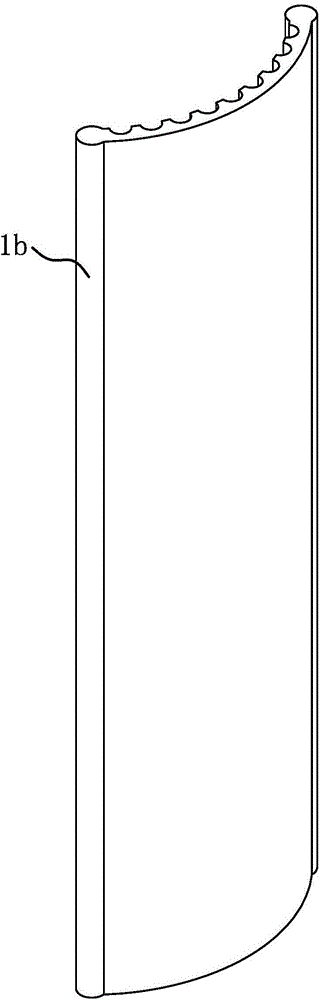

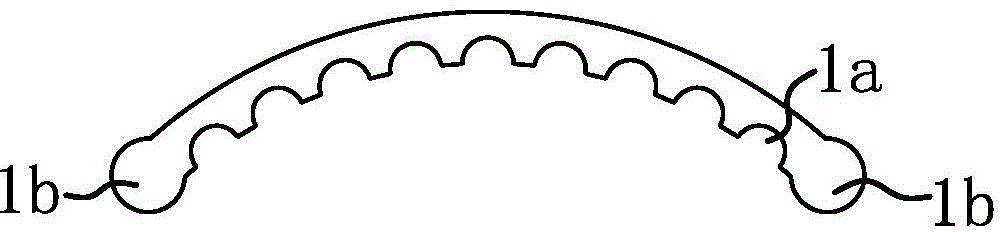

[0035] Such as Figure 1 to Figure 3 As shown, the oil mist separation blade 1 is in the shape of a strip and has an arc-shaped cross section. The concave surface of the oil mist separation blade 1 is provided with several longitudinally extending grooves 1a, and the occupied area of the grooves 1a accounts for 70%-90% of the concave surface of the oil mist separation blade 1 . The number of grooves 1a given in the accompanying drawings is 9, and the cross-sectional shape of the grooves 1a is fan-shaped; according to the actual situation, the number of grooves 1a can be increased or decreased, and the cross-sectional shape of the grooves 1a can also be triangular , trapezoidal or rectangular.

[0036] The corrugated parts 1b on both sides of the oil mist separation blade 1 are cylindrical, and the corrugated parts 1b are higher than the concave surface of the oil mist separation blade 1 .

[0037] The oil mist separation blade 1 can be manufactured by continuous casting of...

Embodiment 2

[0046] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described repeatedly, only the differences are described. The difference lies in: the column 2a of the frame 2 is provided with an oil mist separation blade 1 Corresponding hinged hole 2f and arc-shaped fixing hole 2g, one side corrugated part 1b of the oil mist separation blade 1 is embedded in the hinge hole 2f, and the arc-shaped fixing hole 2g is pierced with a screw 3, and the screw 3 and the oil mist separation blade 1 is connected to the other side corrugated portion 1b. The oil mist separation blade 1 is fixed by screwing the screw 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com