A dust removal device for a vacuum dryer

A vacuum dryer and dust removal device technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of shortening the service life of vacuum pumps, troublesome production operations, etc., achieve long cleaning intervals, and reduce labor Strength, the effect of protecting the vacuum pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

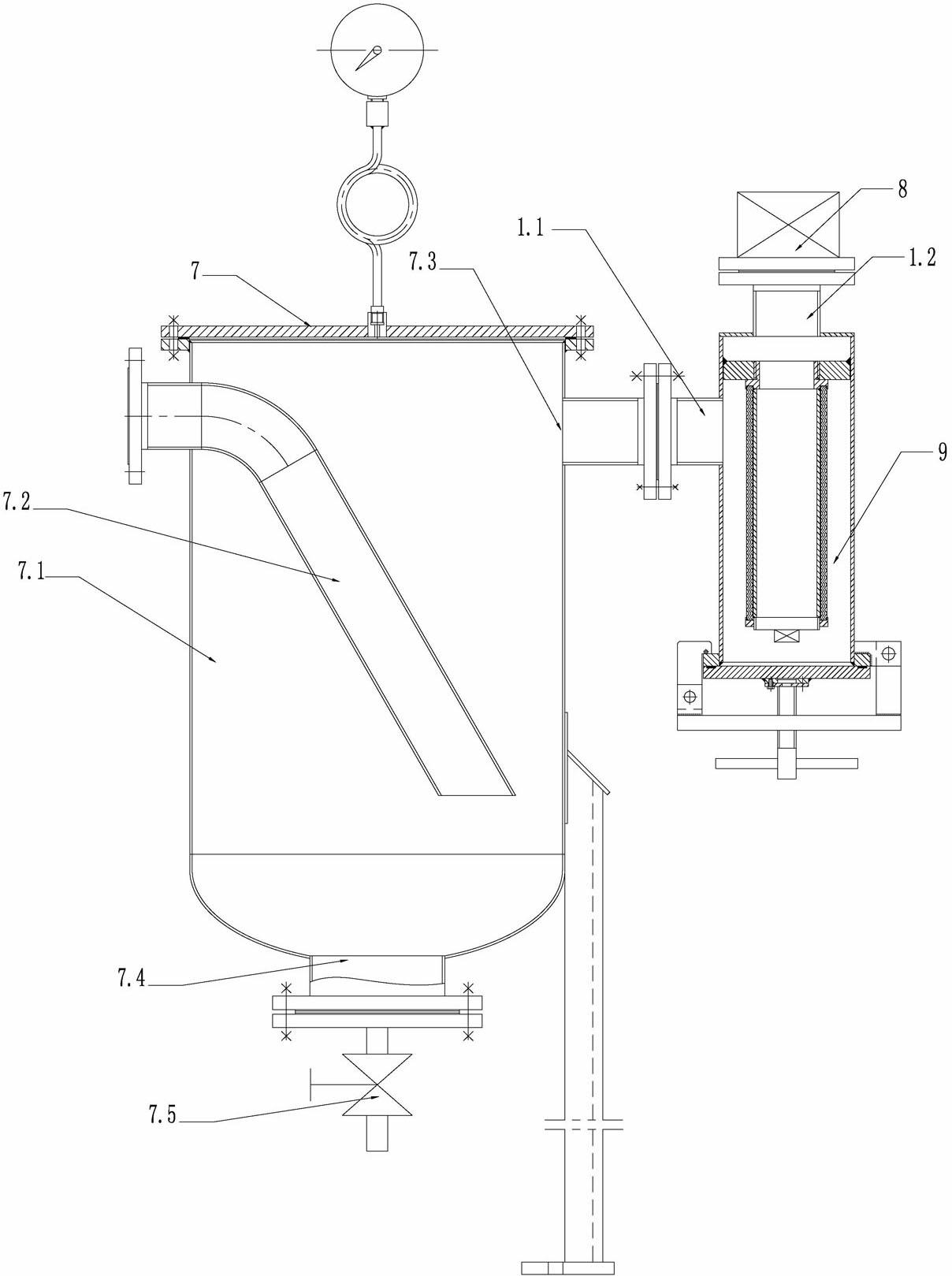

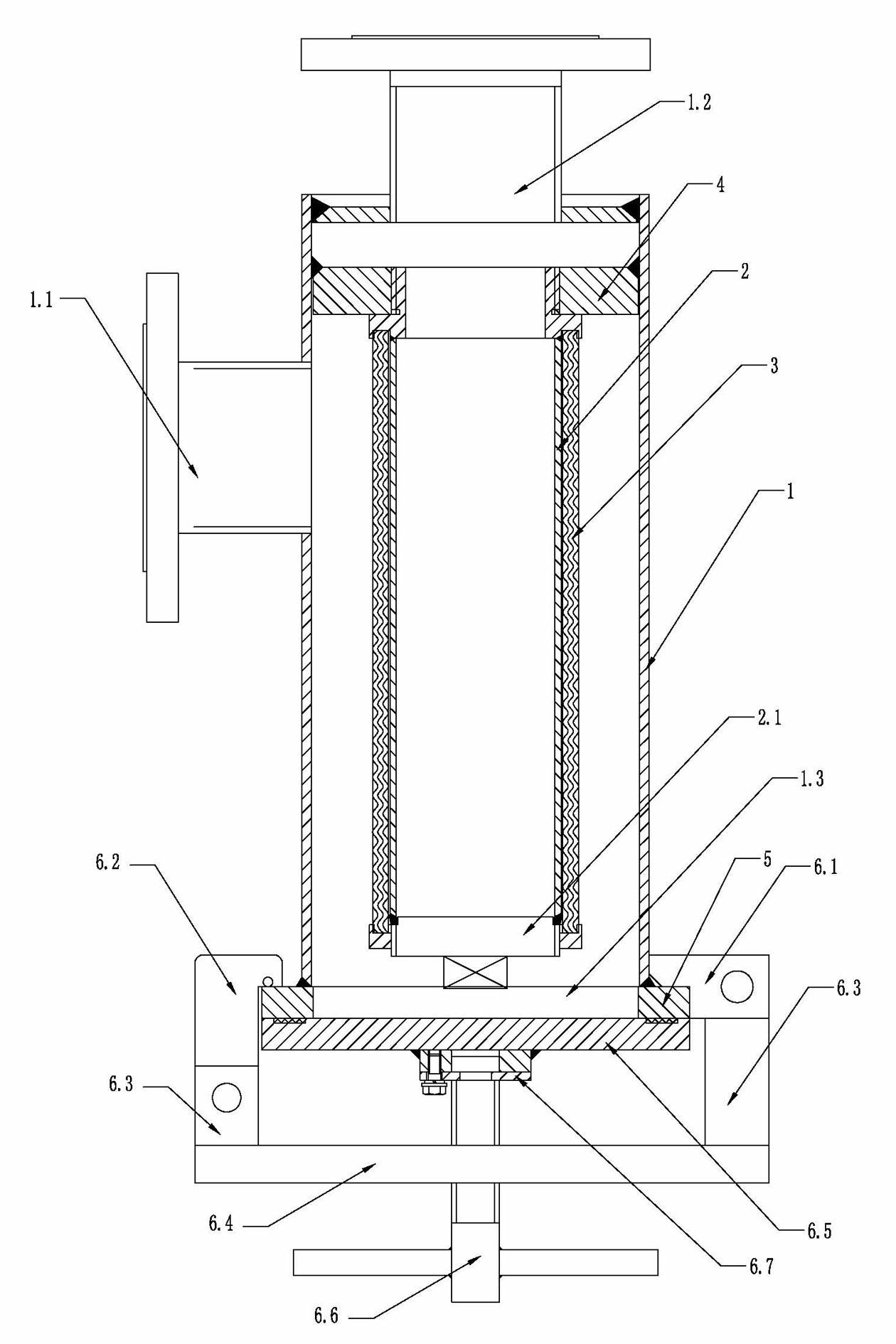

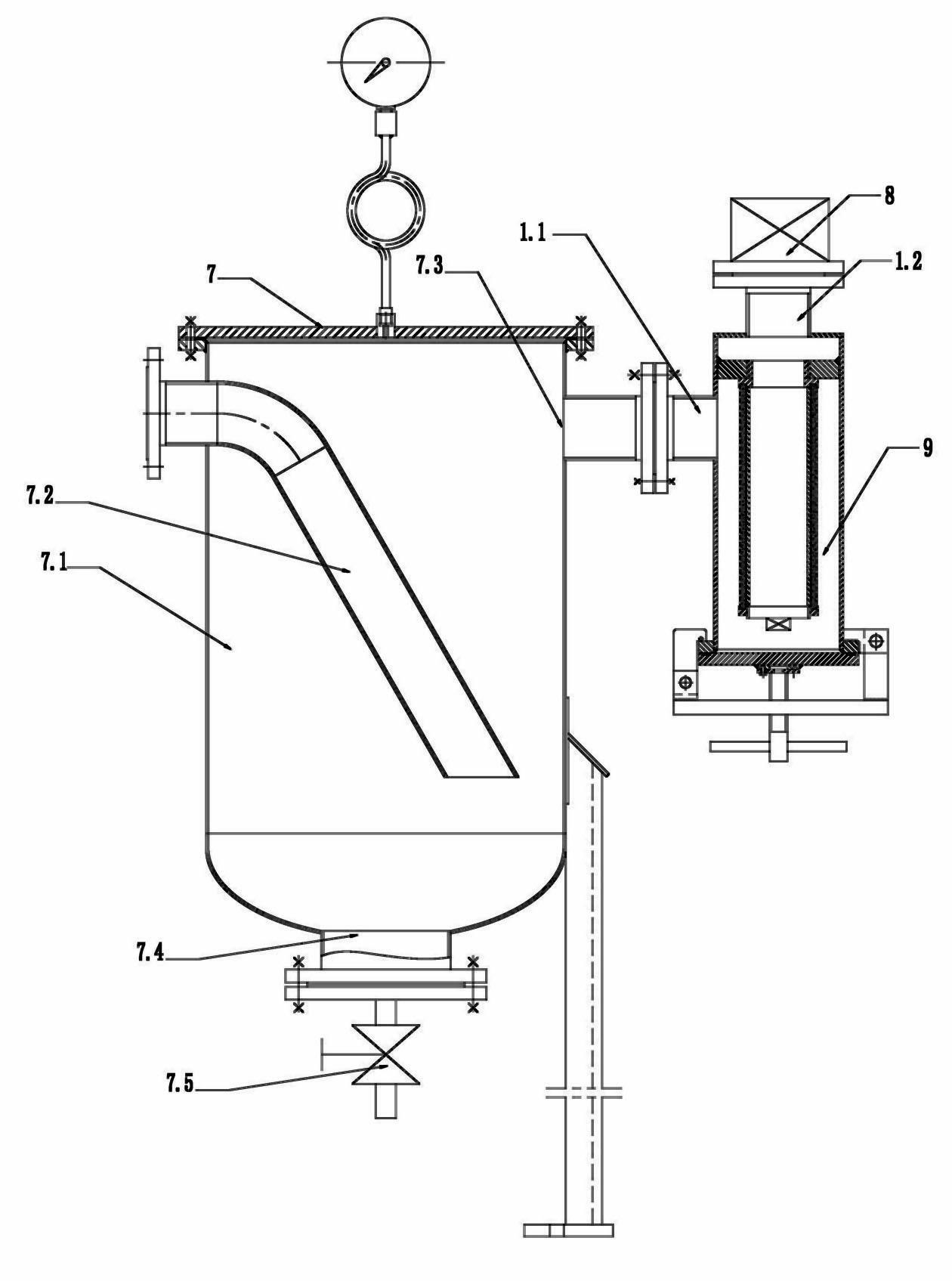

[0012] Such as figure 1 and figure 2 As shown, a dust removal device of a vacuum dryer includes a dust removal barrel 7 and a vacuum pump 8, and is characterized in that the dust removal barrel 7 includes a barrel body 7.1 and an air inlet pipe 7.2, and a vacuum hole 7.3 is provided on the side wall of the barrel body 7.1, and There is a sewage outlet 7.4 at the bottom of the body 7.1, and the air intake pipe 7.2 is inserted into the whole body 7.1; a dust remover 9 is arranged between the dust removal bucket 7 and the vacuum pump 8, and the dust remover 9 includes an outer cylinder 1, a filter tube 2, a filter screen 3, and a filter element fixed Plate 4, flange 5 and quick opening device; there are several through holes on the side wall of filter tube 2; the quick opening device includes ear plate 6.1, hook plate 6.2, connecting plate 6.3, support plate 6.4, cover plate 6.5 and screw rod 6.6, the connection plate 6.3 is respectively fixed at both ends of the support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com