Baking soda preparation device and preparation method

A preparation device and baking soda technology, applied in the field of chemical machinery, can solve problems such as waste of raw materials, imbalance, insufficient reaction of carbonization equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

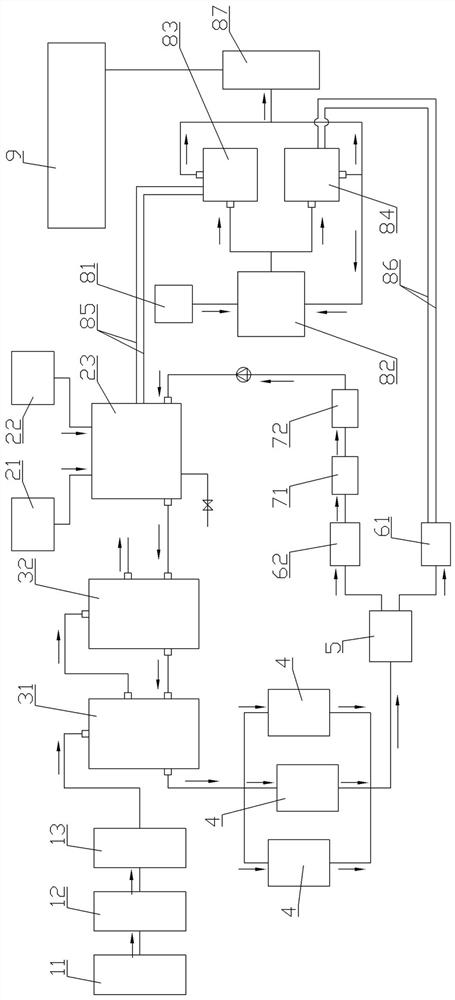

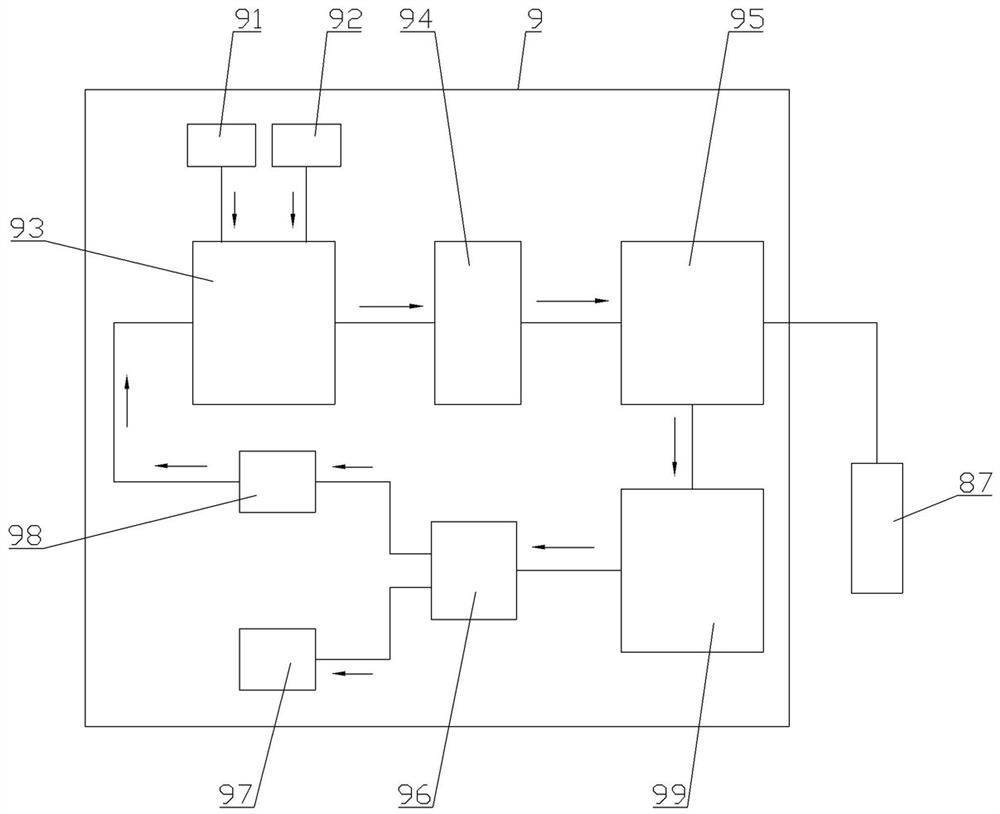

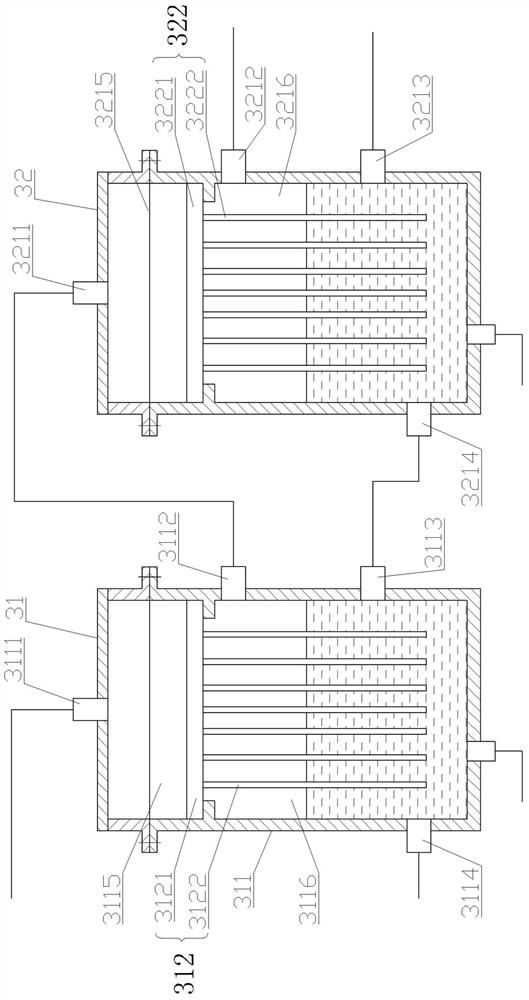

[0072] Such as Figure 1-4 As shown, the baking soda preparation apparatus includes CO 2 Output device, Na 2 CO 3 Solution preparation device, carbonization device, crystallization tank 4, first centrifuge 5, drying bed 61, mother liquor tank 62, mother liquor recovery device, heating device and CaCO 3 Preparation of device 9.

[0073] CO 2 The output device consists of CaCO connected sequentially through pipelines 3 Calcination kiln 11, CO 2 Dust removal and denitrification device 12 and CO 2 Desulfurization tower 13, CO 2 Dust removal and denitrification device 12 is used to remove CaCO 3 Dust and nitrogen oxides in calcination flue gas, CO 2 Desulfurization tower 13 is used to remove CaCO 3 Sulfur oxides in calcination flue gas.

[0074] Na 2 CO 3 The solution preparation unit includes Na 2 CO 3 Storage bin 21, first water supply device 22 and alkali-dissolving tank 23. Na 2 CO 3 The storage bin 21 communicates with the inner chamber of the alkali-dissolvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com