Disc-type micro-filter and filtering method thereof

A filter and disc technology, which is applied to fixed filter element filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of complex structure and poor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

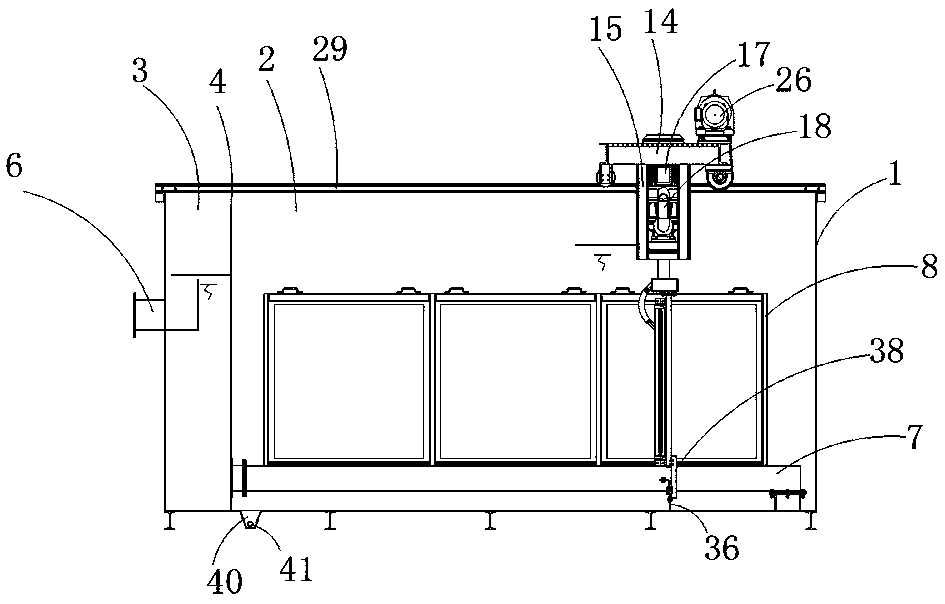

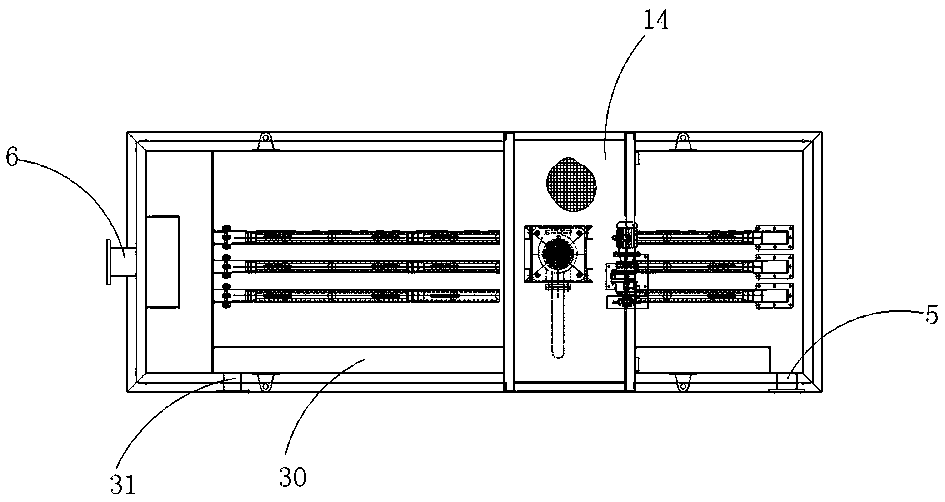

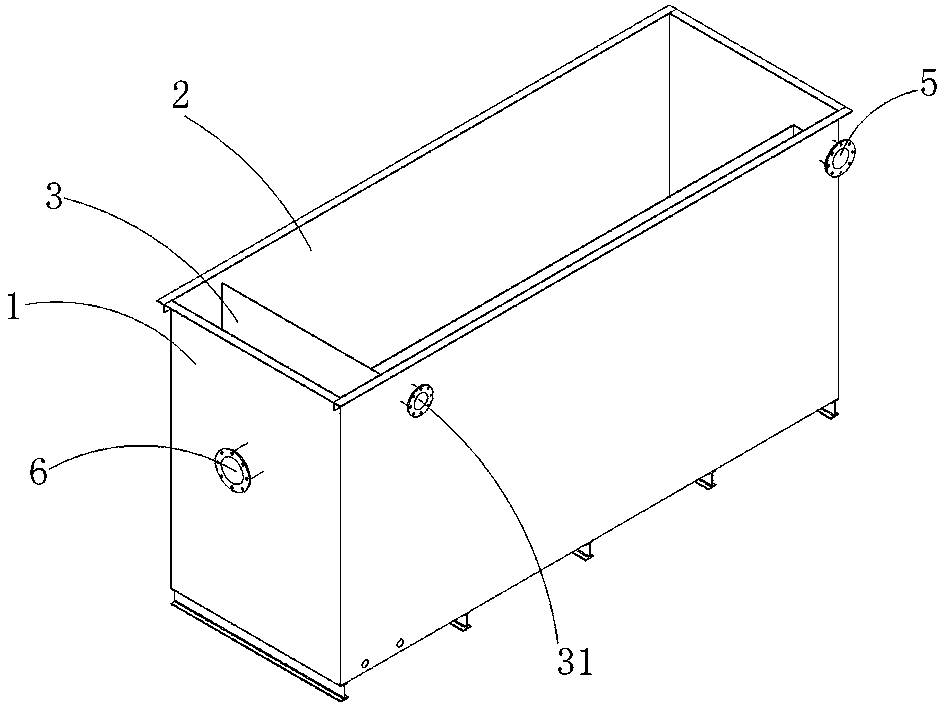

[0088] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a disc type microfilter includes a box body 1, and the box body 1 is provided with a water inlet treatment chamber 2 and a water outlet chamber 3, and the water inlet treatment chamber 2 and the water outlet chamber 3 are separated by an overflow The plates 4 are spaced apart, the bottom of the water inlet treatment chamber 2 is provided with a water outlet horizontal pipe assembly, the water outlet horizontal pipe assembly is provided with a filter plate assembly, and the upper part of the box body 1 is provided with a trolley assembly, The trolley assembly slides along the upper part of the box body 1, the bottom of the trolley assembly is provided with a backwash assembly matched with the filter plate assembly, and the bottom of the backwash assembly is provided with a mud scraper assembly. The mud scraping assembly is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com