Cooling device in rotating drum core part for preventing latex bonding in concentration and separation process

A cooling device and separation process technology, applied in the direction of centrifuges, etc., can solve the problems of separation effect decline, material clogging, etc., and achieve the effects of avoiding generation and growth, improving quality, reducing space occupation and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

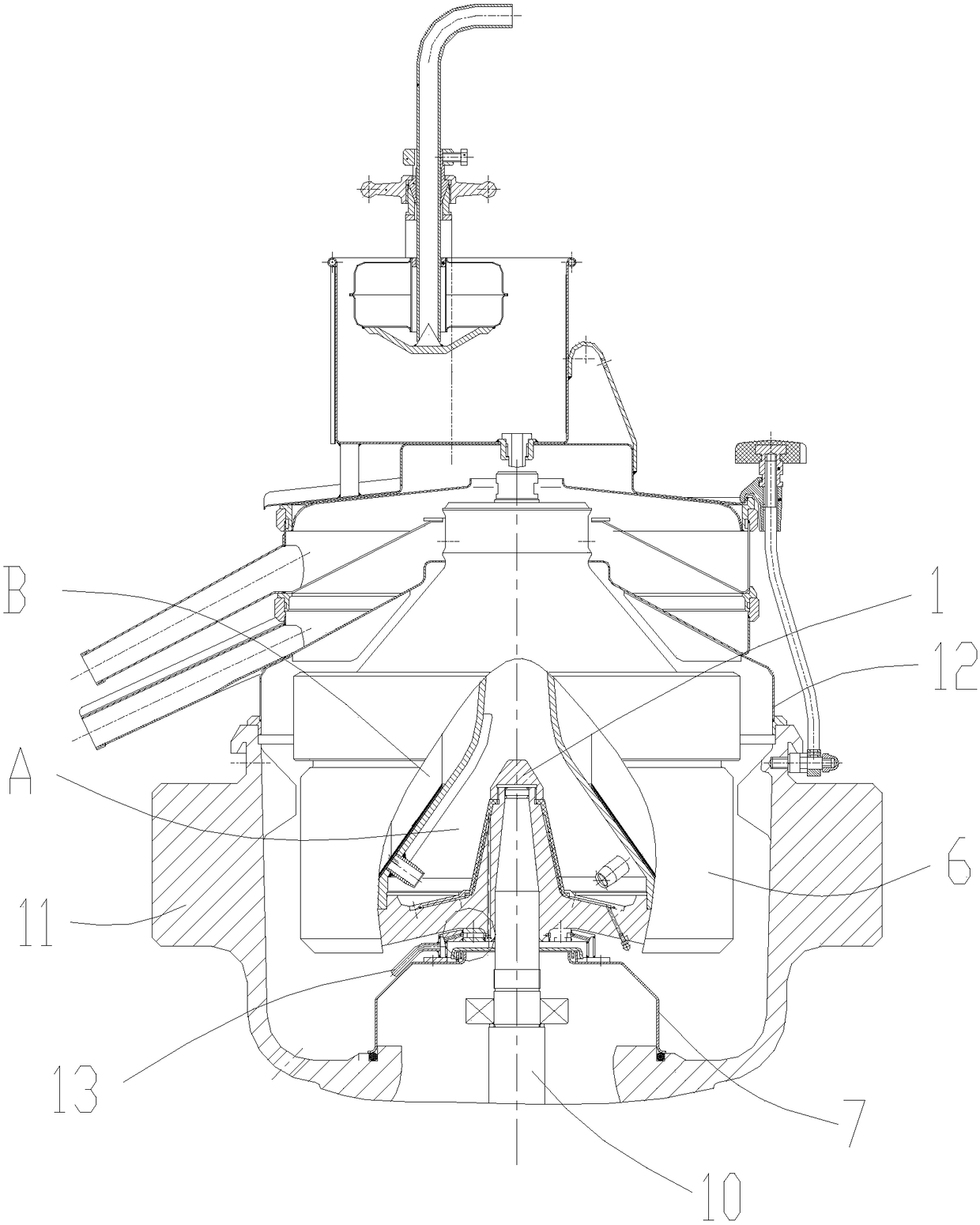

[0024] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0025] see figure 1 , the present embodiment is a drum core cooling device for preventing latex concentration and separation process bonding, one end of the vertical shaft 10 is located in the base 11 and connected to the core of the drum 6 in the base 11, and is located in the cavity of the base 11 A bearing 9 is arranged on the vertical shaft 10, and a protective cover assembly is arranged between the bearing 9 and the core of the rotating drum 6.

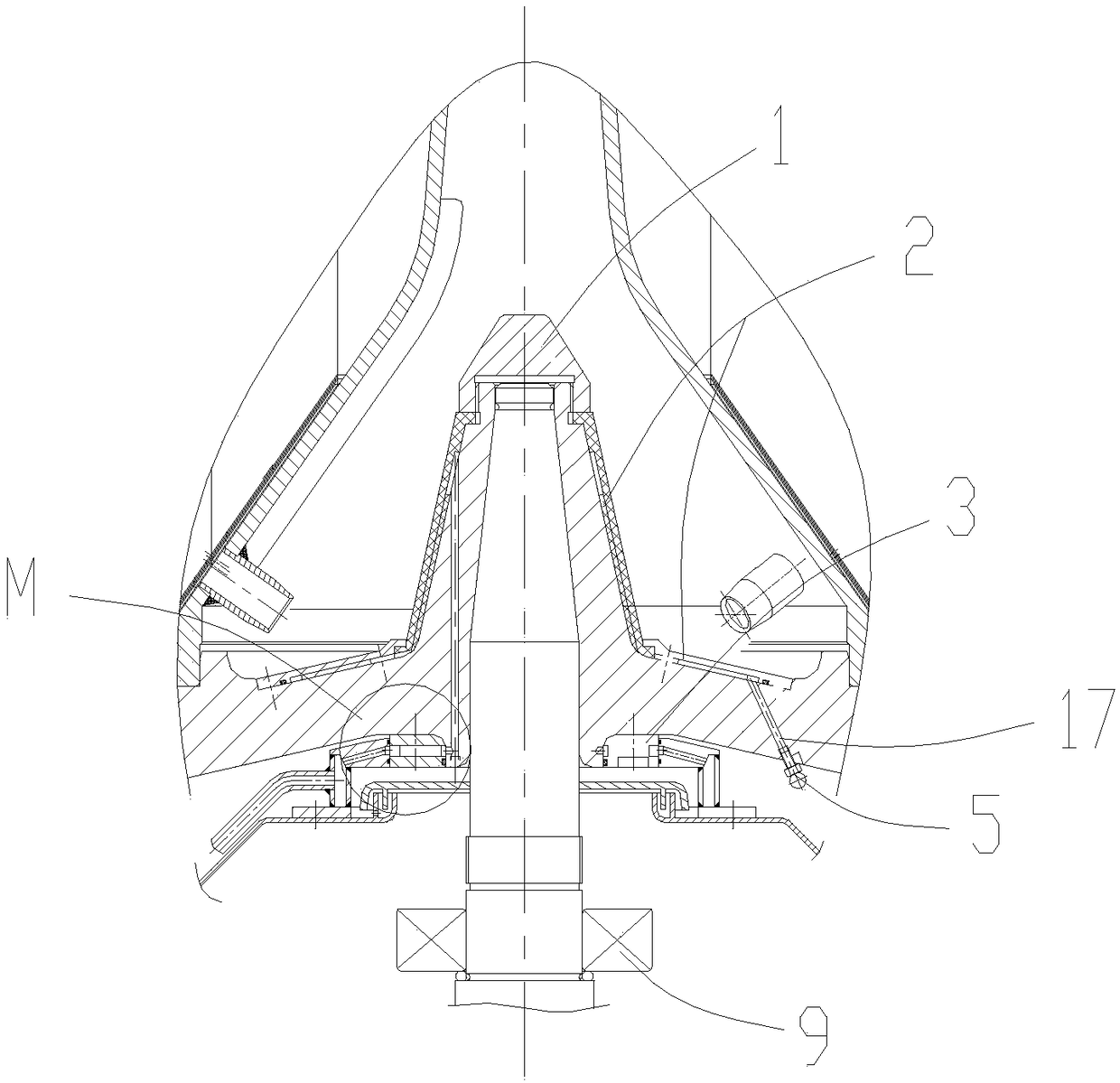

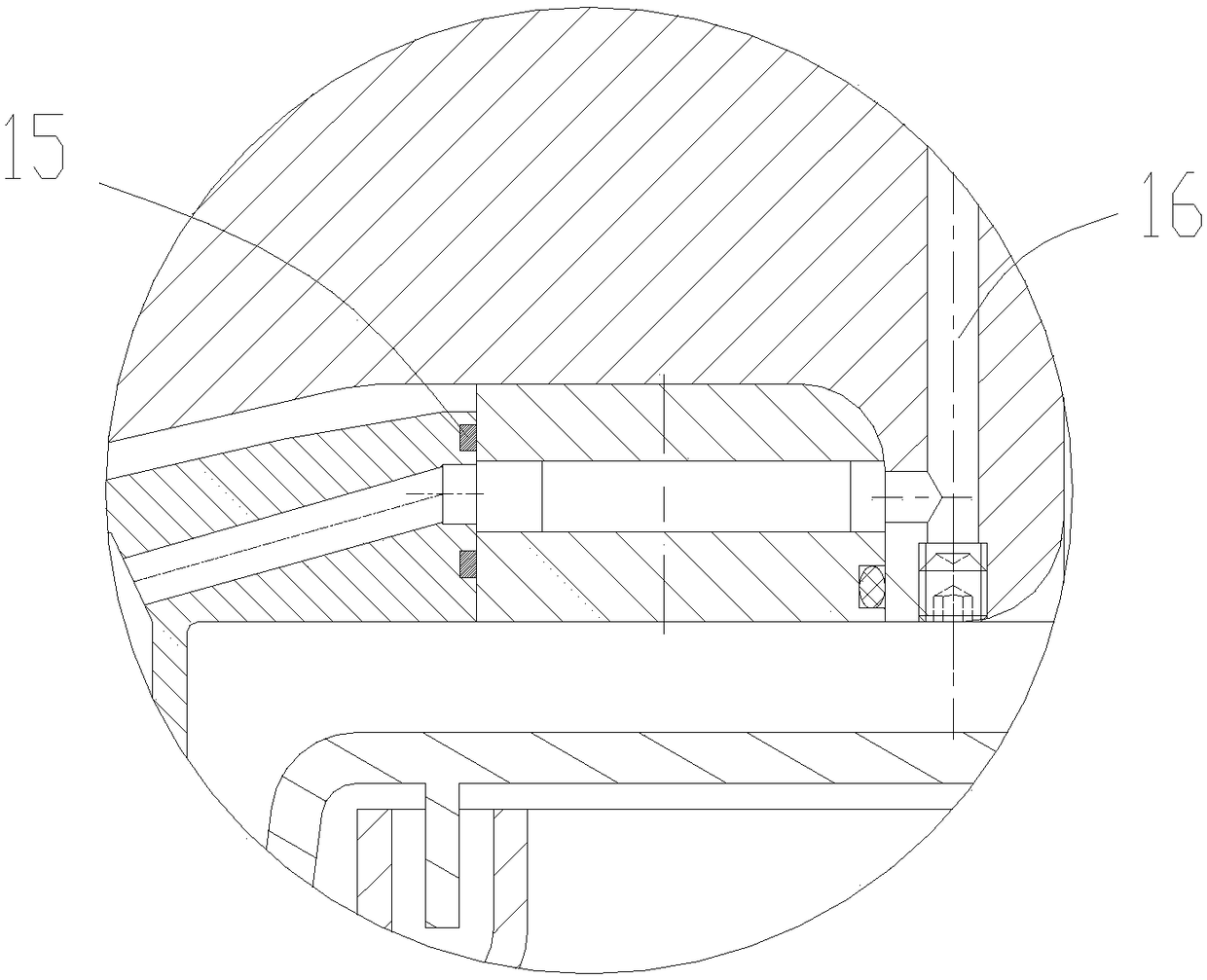

[0026] A core cooling device 2 is arranged on the surface of the core of the drum 6, and a centripetal pump 3 is arranged at the connection between the vertical shaft 10 and the bottom of the core of the drum 6, such as figure 2 shown. Centripetal pump 3 is a cylindrical structure with 8 helical blades, see Figure 4 , there are three screw holes conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com