Dust bag type dust removal process under disordered and uneven state

A dust and process technology, applied in the field of dust bag dust removal technology, can solve the problems of unsatisfactory dust removal effect and great influence of physical and chemical characteristics of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

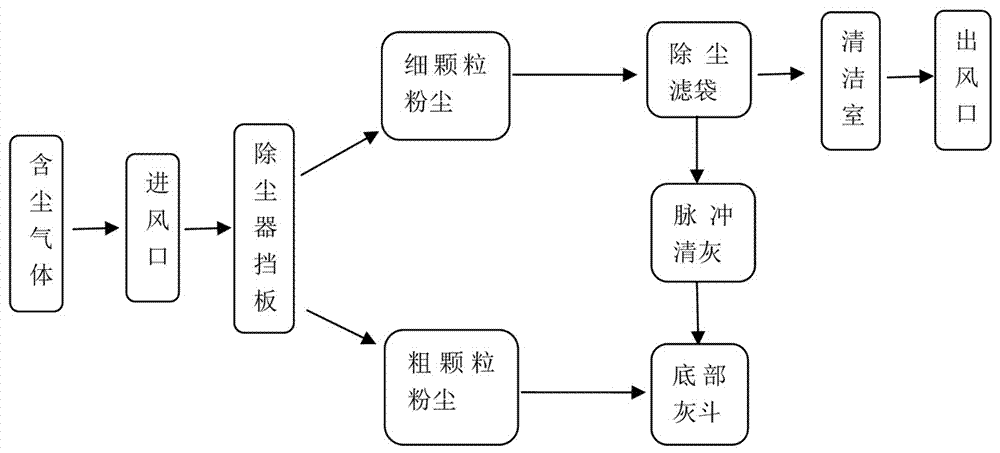

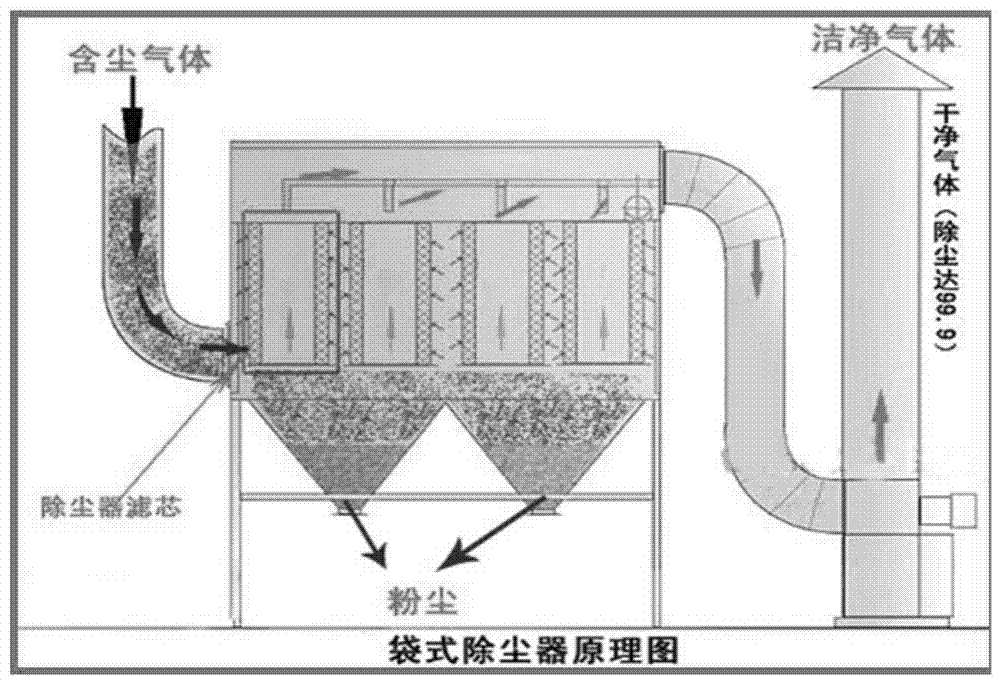

[0015] The dust-laden gas enters the dust collector from the air inlet, first hits the inclined plate and baffle in the middle of the air inlet and outlet, the airflow turns to flow into the ash hopper, and at the same time, the airflow speed slows down. Due to inertia, the coarse particles in the gas flow directly into the ash hopper. . It plays a role of pre-collection of dust. The airflow entering the ash hopper is then folded upwards and passes through the filter bag with a metal skeleton inside. The dust is trapped on the outer surface of the filter bag. The purified gas enters the upper clean room of the filter bag chamber and is collected to the outlet. Air outlet,

[0016] In the process of purifying dusty gas through the filter bag, more and more dust accumulates on the filter bag with the increase of time, which increases the resistance of the filter bag, resulting in a gradual decrease in the air volume. For normal work, the resistance must be controlled at a certain l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com