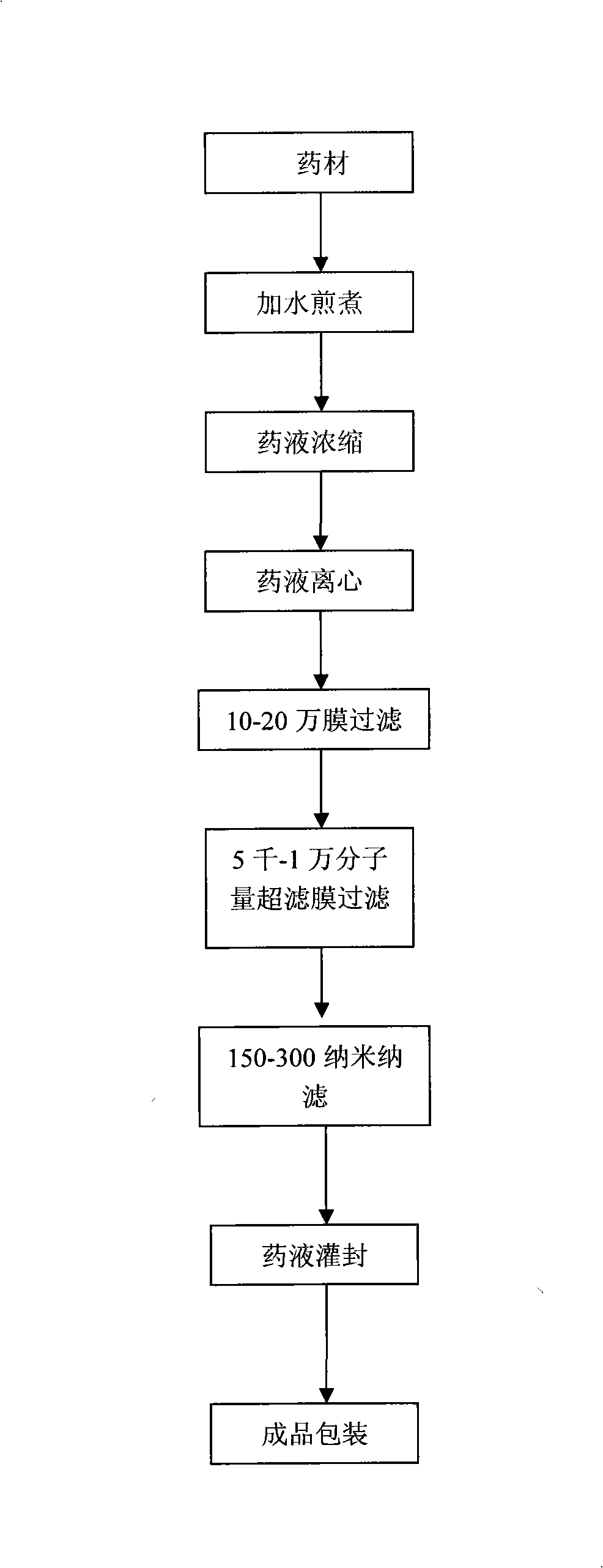

Process for preparing compound folium isatidis injection with membrane filter technique

A Folium Folium, membrane filtration technology, applied in the direction of medical formula, medical preparations containing active ingredients, drug delivery, etc., can solve the problems of loss of active ingredients, increase pollution, consumption of organic solvents, etc., to reduce the loss of active ingredients, The effect of reducing pollution links and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 1000g of Daqingye, 500g of honeysuckle, 250g of notopterygium, 250g of ginseng, and 250g of rhubarb, and add water to decoct three times. The amount of water added is 8, 6, and 6 times, each time for 1 hour. The filtrate is concentrated to 3 times the amount of Folium Folium medicinal material. Centrifuge the medicinal liquid at high speed (rotating speed is 18000r / min), filter it with a ceramic membrane with a molecular weight of 200,000, heat the filtrate to 80°C, adjust the pH value to 8.0 with 1% sodium hydroxide, cool to room temperature, and then use a ceramic membrane with a molecular weight of 10,000 Ceramic ultrafiltration membrane filtration, the ultrafiltrate is concentrated by 200nm nanofiltration membrane filtration to about 1 times the amount of Folium Folium, the content, resin, tannin, protein and other impurities are qualified, and a small test is done to detect abnormal toxicity, After the endotoxin is qualified, prepare potting as a spare solutio...

Embodiment 2

[0033] Take 1000g of Daqingye, 500g of honeysuckle, 250g of notopterygium, 250g of ginseng, and 250g of rhubarb, and add water to decoct three times. The amount of water added is 8, 6, and 6 times, each time for 1 hour. The filtrate is concentrated to 3 times the amount of Folium Folium medicinal material. Centrifuge the medicinal liquid at high speed (15000r / min), filter it with a hollow fiber membrane with a molecular weight of 150,000, heat the filtrate to 80°C, adjust the pH value to 8.0 with 1% sodium hydroxide, cool to room temperature, and then filter with a molecular weight of 10,000 The hollow fiber ultrafiltration membrane is used for filtration, and the ultrafiltrate is filtered with a 300nm nanofiltration membrane to concentrate to about 1 times the amount of Folium Folium. The detected content, resin, tannin, protein and other impurities are qualified. Do a small test and then detect abnormalities After the toxicity and endotoxin are qualified, it is prepared as a...

Embodiment 3

[0036] Take 1000g of Daqingye, 500g of honeysuckle, 250g of notopterygium, 250g of ginseng, and 250g of rhubarb, and add water to decoct three times. The amount of water added is 8, 6, and 6 times, each time for 1 hour. The filtrate is concentrated to 3 times the amount of Folium Folium medicinal material. Centrifuge the medicinal liquid at high speed (rotating speed is 10000r / min), filter it with a ceramic membrane with a molecular weight of 100,000, heat the filtrate to 80°C, adjust the pH value to 8.0 with 10% sodium carbonate, cool to room temperature, and then filter it with a ceramic ultrafiltration membrane with a molecular weight of 5000. Membrane filtration, the ultrafiltrate is filtered with a 150nm nanofiltration membrane and concentrated to about 1 times the amount of Folium Folium, the content, resin, tannin, protein and other impurities are tested to be qualified, and a small test is done to detect abnormal toxicity and endotoxin After passing the test, prepare p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com