Liquid phase sintering additive for tetragonal polycrystalline zirconia ceramic material and preparation and application thereof

A zirconia ceramic and liquid phase sintering technology, applied in the field of zirconia ceramic sintering, can solve the problems of strict requirements on sintering equipment, high final cost of products, and restrictions on wide use, etc. and the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

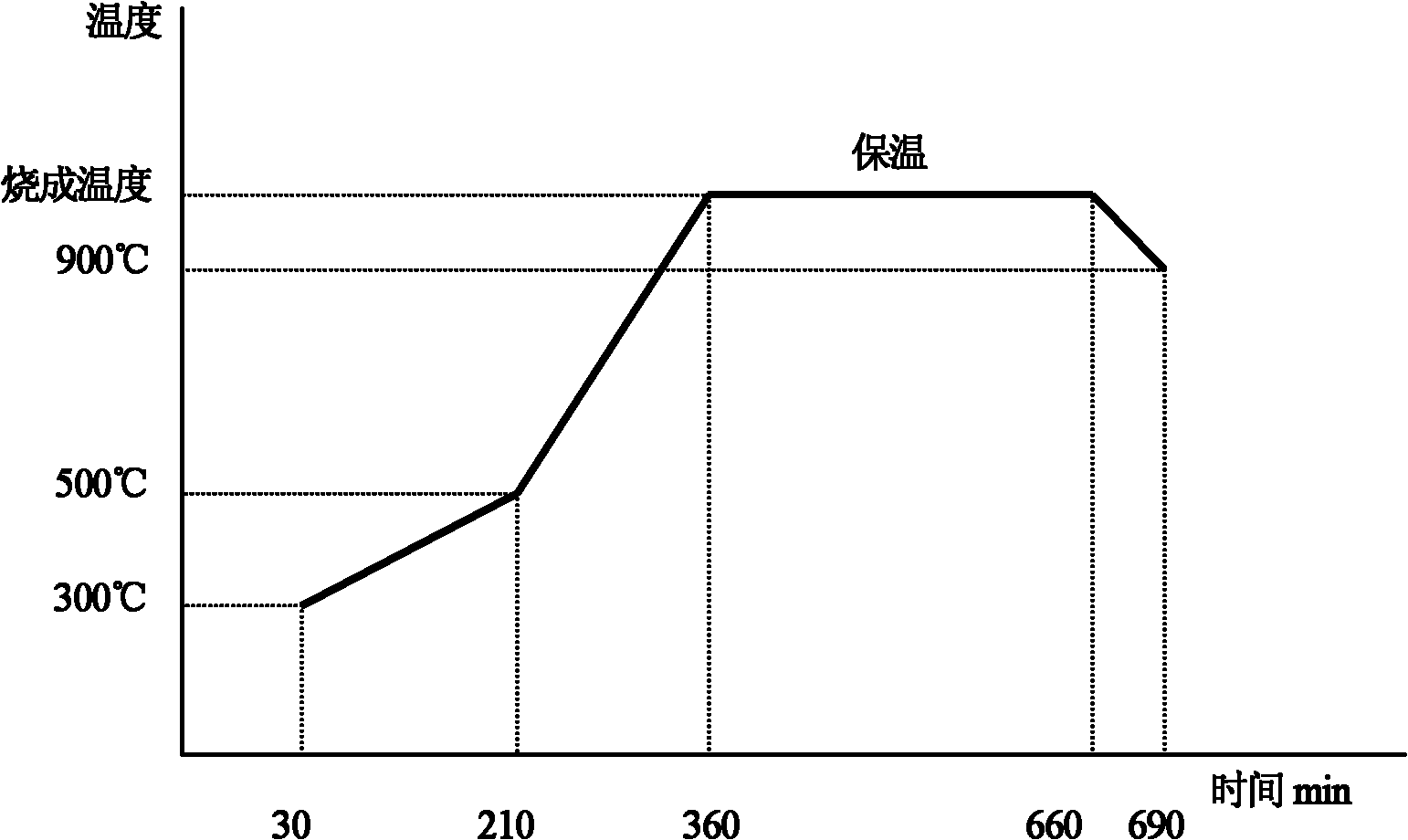

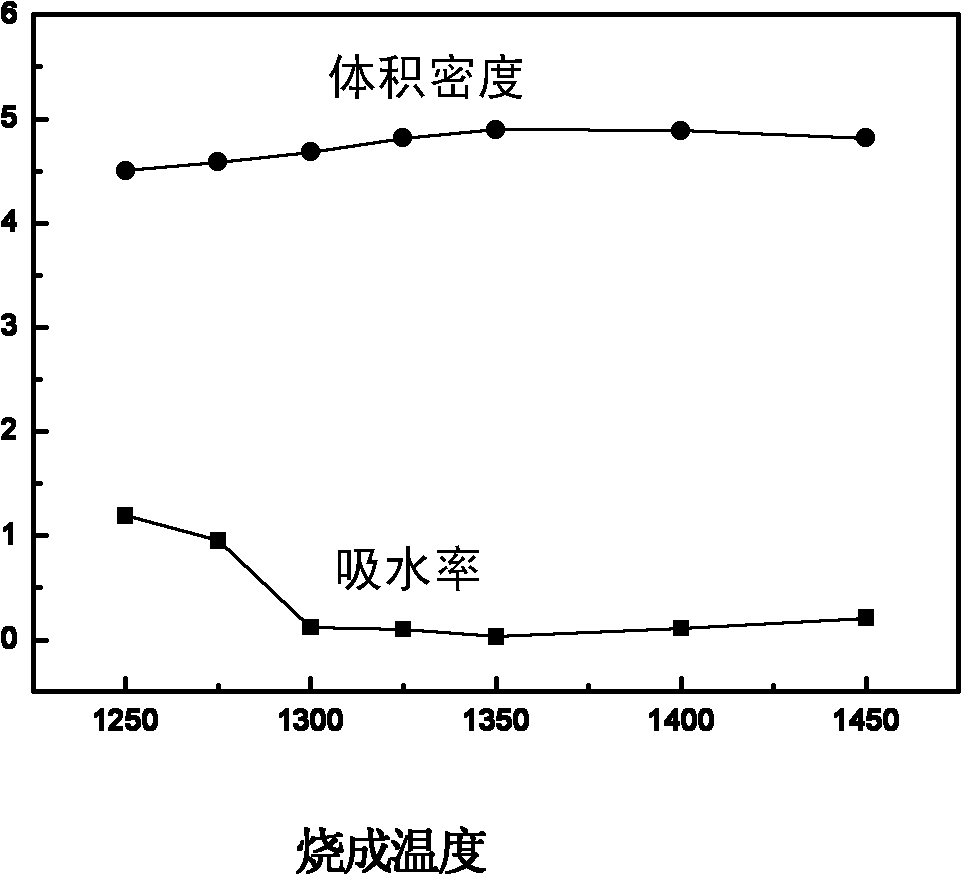

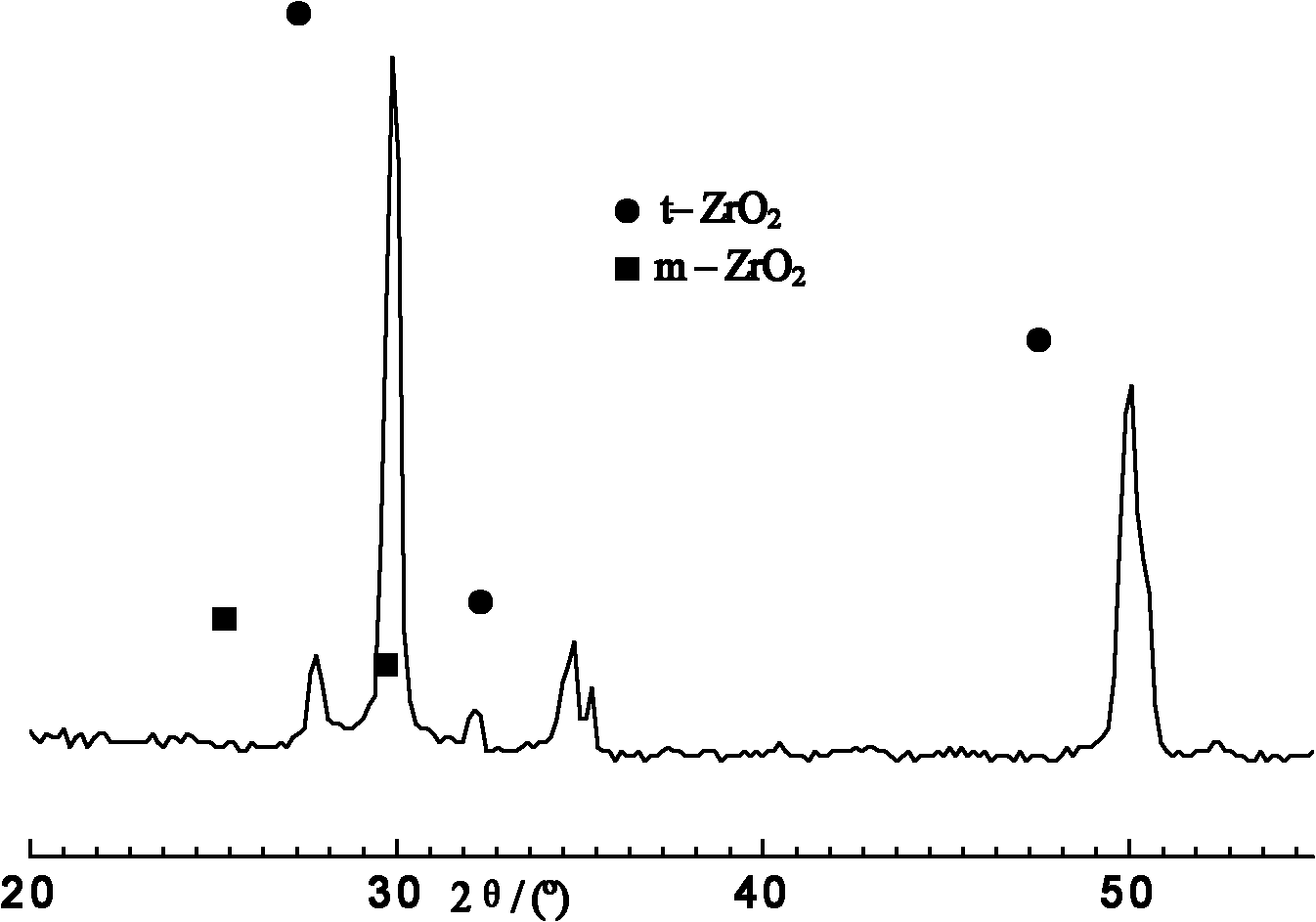

Method used

Image

Examples

Embodiment 1

[0035] Table 1 embodiment 1 glass powder flux formulation

[0036] Element

SiO 2

CaO

Al 2 o 3

Na 2 o

B 2 o 3

Wt%

43

14.8

27

52

10

[0037] Design the glass component formula according to Table 1, the total batching amount is 5Kg, pour all into the crucible, melt in the drawer kiln until clarification, keep warm for 150min, and obtain a uniform and transparent glass liquid without obvious bubbles. The above molten glass was cast into a 100 mm long strip, and the two end faces were ground parallel to make a glass strip sample A.

[0038] Then all the remaining glass liquid is poured into water for quenching and quenching to form glass particles of 2-6mm, and the above-mentioned glass particles are collected for wet grinding in a ball mill jar, and 0.2wt% sodium tripolyphosphate is added as a grinding aid, material: ball: Water=1:2:(0.4-0.5), ball milled for 12 hours, and passed through a 800-mesh si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com