Clean extraction method of tea saponin

An extraction method and technology for tea saponin, which are applied in chemical instruments and methods, solid solvent extraction, preparation of sugar derivatives, etc., can solve the problems of difficulty in subsequent purification, large input of equipment and raw materials, and many impurities, and achieve single-stage separation. High efficiency, improve the utilization rate of raw materials, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

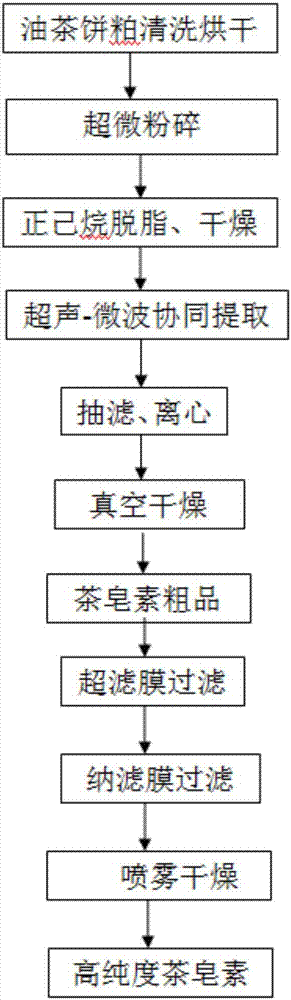

Image

Examples

Embodiment 1

[0038] The present embodiment provides the cleaning extraction method of tea saponin, and the steps include:

[0039] 1) Use distilled water to clean the surface dust and other sundries of the camellia oleifera cake, dry it at a temperature of 50°C to constant weight, then pulverize the camellia oleifera cake with an ultrafine pulverizer, and sieve it to a fineness of 200 mesh;

[0040] 2) Take camellia oleifera cake powder, add n-hexane according to the material-to-liquid ratio of 1:2, heat to 60°C, reflux for 1 hour to degrease, and then dry;

[0041] 3) Take defatted camellia oleifera cake powder, add ethanol with a concentration of 75% according to the ratio of material to liquid 1:15, heat to 50°C, and carry out ultrasonic-microwave synergistic extraction, ultrasonic frequency 15KHz, ultrasonic power 300W, microwave power 200W, extraction time 10min;

[0042] 4) Suction filtration and centrifugation of the extracted solution to obtain a tea saponin extract;

[0043] 5) ...

Embodiment 2

[0046] The present embodiment provides the cleaning extraction method of tea saponin, and the steps include:

[0047] 1) Use distilled water to clean the surface dust and other sundries of the camellia oleifera cake, dry it at a temperature of 60°C to constant weight, then pulverize the camellia oleifera cake with an ultrafine pulverizer, and sieve it to a fineness of 400 mesh;

[0048] 2) Take camellia oleifera cake powder, add n-hexane according to the material-to-liquid ratio of 1:3, heat to 70°C, reflux for 3 hours for degreasing treatment, and then dry;

[0049] 3) Take defatted camellia oleifera cake powder, add ethanol with a concentration of 75% according to the ratio of material to liquid 1:25, heat to 70°C, and perform ultrasonic-microwave synergistic extraction. The ultrasonic-microwave synergistic extraction method is: a) the The solution to be extracted is placed in an ultrasonic-microwave reactor; b) Control the ultrasonic introduction device to open, the ultraso...

Embodiment 3

[0054] The present embodiment provides the cleaning extraction method of tea saponin, and the steps include:

[0055] 1) Use distilled water to clean the camellia oleifera cake surface dust and other sundries, dry it at a temperature of 55° C. to constant weight, then use an ultrafine pulverizer to pulverize the camellia oleifera cake, and sieve it to a fineness of 300 mesh;

[0056] 2) Take camellia oleifera cake powder, add n-hexane according to the material-to-liquid ratio of 1:2.5, heat to 65°C, reflux for 2 hours to degrease, and then dry;

[0057] 3) Take defatted camellia oleifera cake powder, add ethanol with a concentration of 75% according to the ratio of material to liquid 1:20, heat to 60°C, and perform ultrasonic-microwave synergistic extraction. The ultrasonic-microwave synergistic extraction method is: a) the The solution to be extracted is placed in an ultrasonic-microwave reactor; b) control the ultrasonic introduction device to open, the ultrasonic frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com