Equipment and method for preparing anhydrous sodium sulfate

A technology of anhydrous sodium sulfate and sodium sulfate, applied in the direction of alkali metal sulfite/sulfate dehydration, etc., can solve the problems of complex industry, large investment in equipment at one time, high energy consumption of sodium sulfate evaporation and crystallization, and achieve low energy consumption, Good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

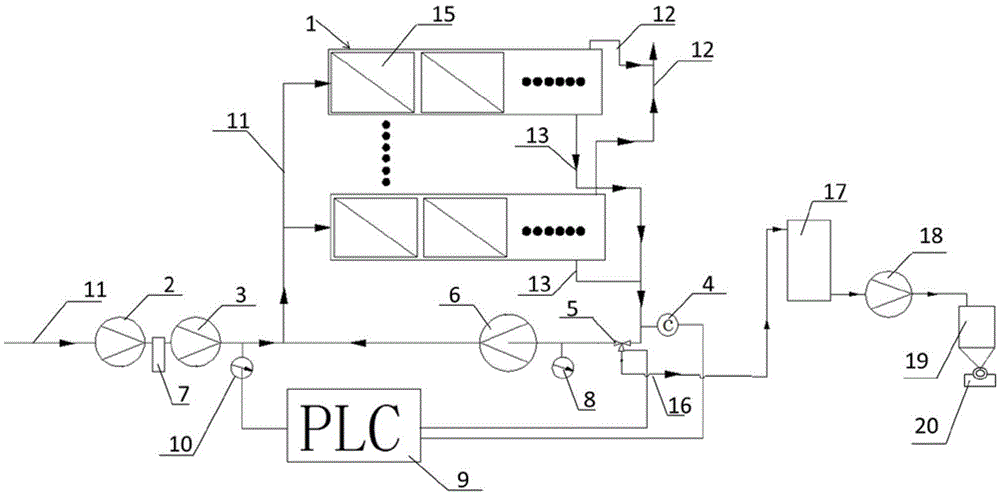

[0032] Such as figure 1 Shown, a preferred embodiment of the present invention provides a kind of equipment for preparing anhydrous sodium sulfate, comprises the closed-circuit circulation membrane concentrating system, salting-out system 17, delivery pump 18 and normal temperature crystallization system connected successively; Wherein, closed-circuit circulation The membrane concentration system is used to concentrate the incoming liquid containing sodium sulfate and discharge the concentrated solution containing supersaturated sodium sulfate, and the salting-out system 17 is used to convert the sodium chloride-sodium sulfate-water ternary system in the concentrated solution into an unsaturated solution. In a stable system, the delivery pump 18 is used to transport the concentrated solution discharged from the salting-out system to the normal temperature crystallization system, and the normal temperature crystallization system is used to carry out normal temperature crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com