Method for improving surface hydrophilicity of waste rubber powder

A waste rubber powder, hydrophilic technology, applied in the field of surface modification of waste rubber powder, to achieve the effect of low energy consumption, excellent comprehensive performance and narrow distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

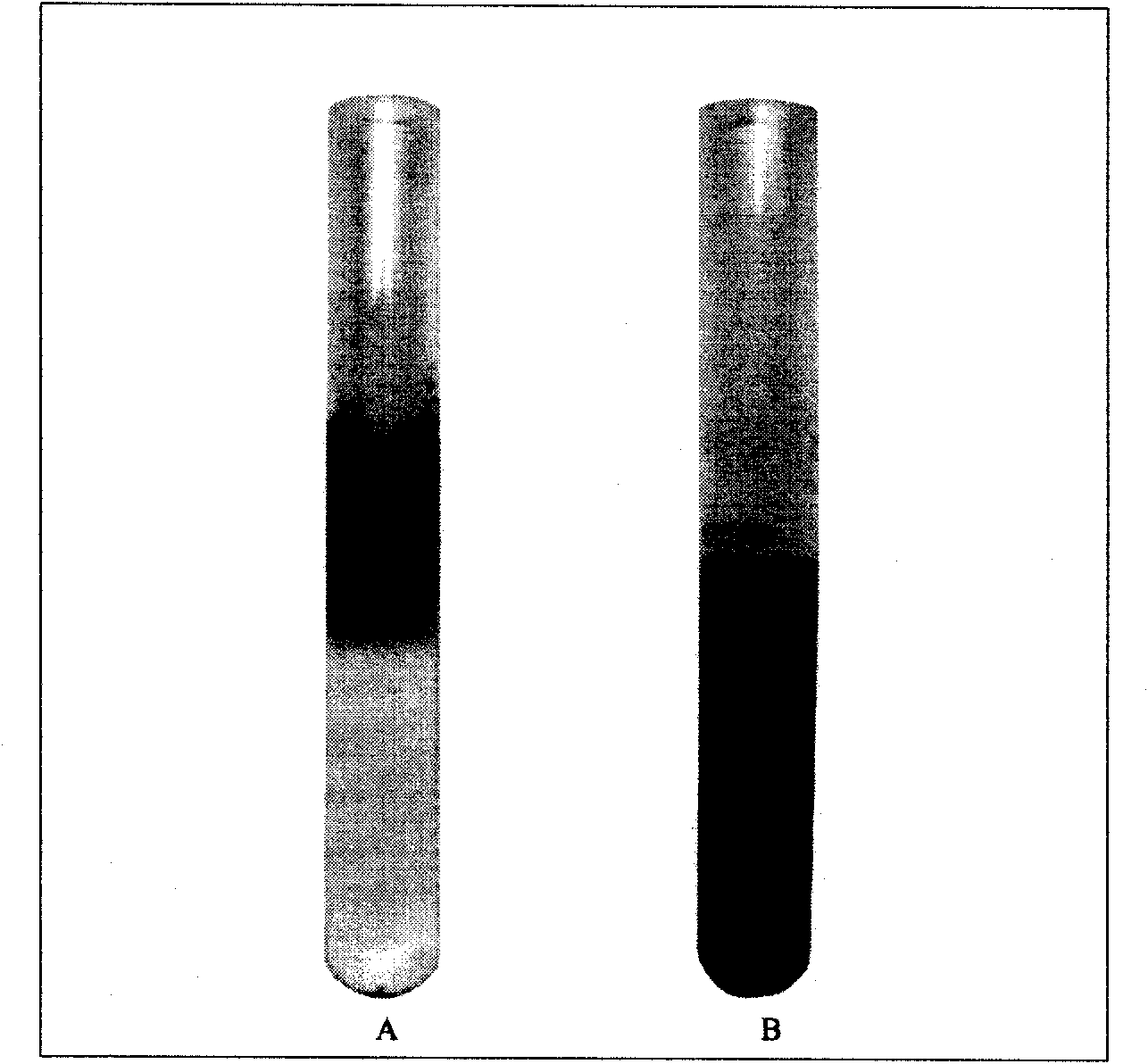

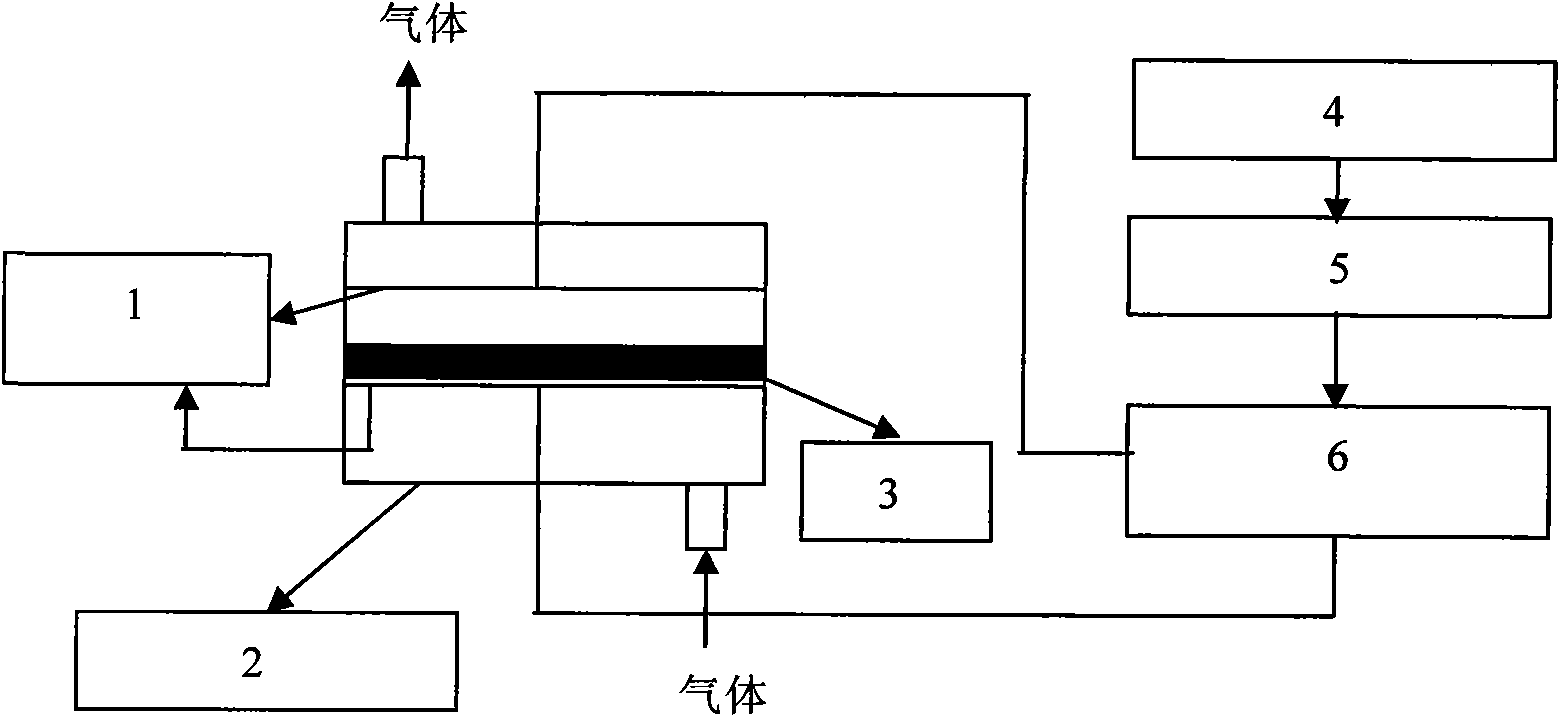

[0039] Put 10 parts of waste tire rubber powder in a plasma treatment device. like figure 1 As shown (or add a plasma transmission device to realize continuous production), the container or carrier is placed under the room temperature and atmospheric pressure plasma spray device, the distance from the upper quartz plate is 2mm, and the waste rubber powder is laid on the bottom with a diameter of 70mm. In a quartz glass vessel, the average thickness of the rubber powder is about 1mm. The plasma equipment was turned on, and the plasma treatment was performed at room temperature and in an air atmosphere. The treatment time was 300s, and the power was 10W.

Embodiment 2

[0041] Place 100 parts of waste fluororubber powder in special equipment for plasma treatment. like figure 1 As shown (or add a plasma transmission device to realize continuous production), the container or carrier is placed under the room temperature and atmospheric pressure plasma spray device, the distance from the upper quartz plate is 2mm, and the waste rubber powder is laid on the bottom with a diameter of 70mm. In a quartz glass vessel, the average thickness of the rubber powder is 1mm. The plasma equipment was turned on, and plasma treatment was performed at room temperature in a nitrogen atmosphere, the treatment time was 2s, and the power was 5000W.

Embodiment 3

[0043] Put 60 parts of the waste moisture-proof pad rubber powder in the special equipment for plasma treatment. like figure 1As shown, the container or carrier is placed under normal pressure and room temperature plasma spraying device, the distance from the upper quartz plate is 2mm, and the waste rubber powder is spread in the quartz glass vessel with a diameter of 70mm below, and the rubber powder is spread evenly. The thickness is 1mm. The plasma equipment was turned on, and plasma treatment was performed in an atmosphere with a molar ratio of air to nitrogen of 1 and a molar ratio of acrylic acid vapor to nitrogen of 0.1, with a treatment time of 120 s and a power of 80 W.

[0044] Table 1 Variation of water contact angle of waste rubber powder with plasma treatment power (waste tire rubber powder, treatment time is 120s)

[0045]

[0046] Table 2 Variation of water contact angle of waste rubber powder with plasma treatment time

[0047]

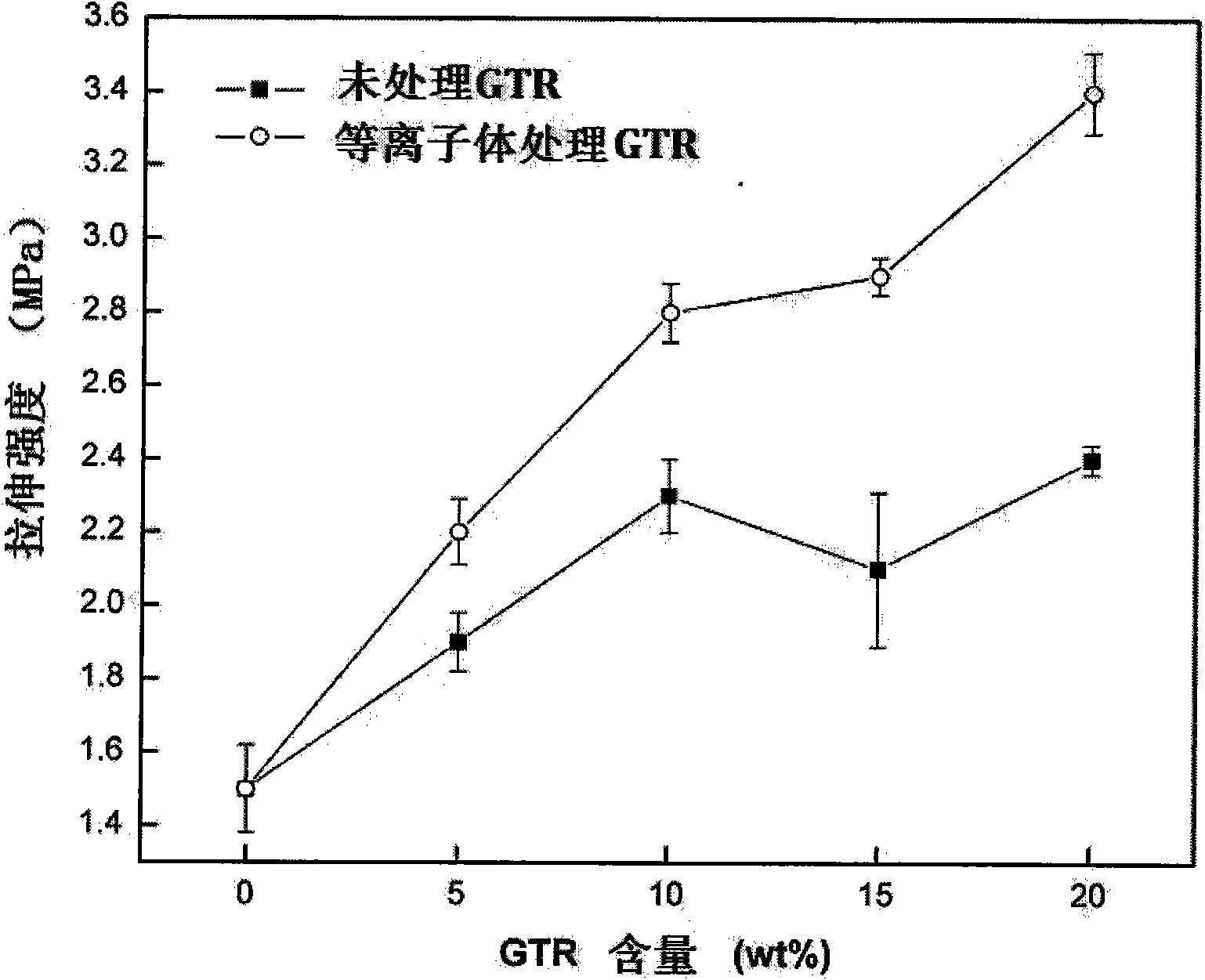

[0048] Table 3 Surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com