Preparation method of monodisperse-metal oxide magnetic composite microsphere resisting acid and magnetic composite microsphere

A magnetic composite microsphere, acid-resistant technology, applied in the direction of microsphere preparation, chemical/physical/physicochemical process of energy application, microcapsule preparation, etc., can solve the problems that carbon-oxide magnetic composite materials have not been reported, and achieve The effect of being convenient for large-scale production, mild reaction conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

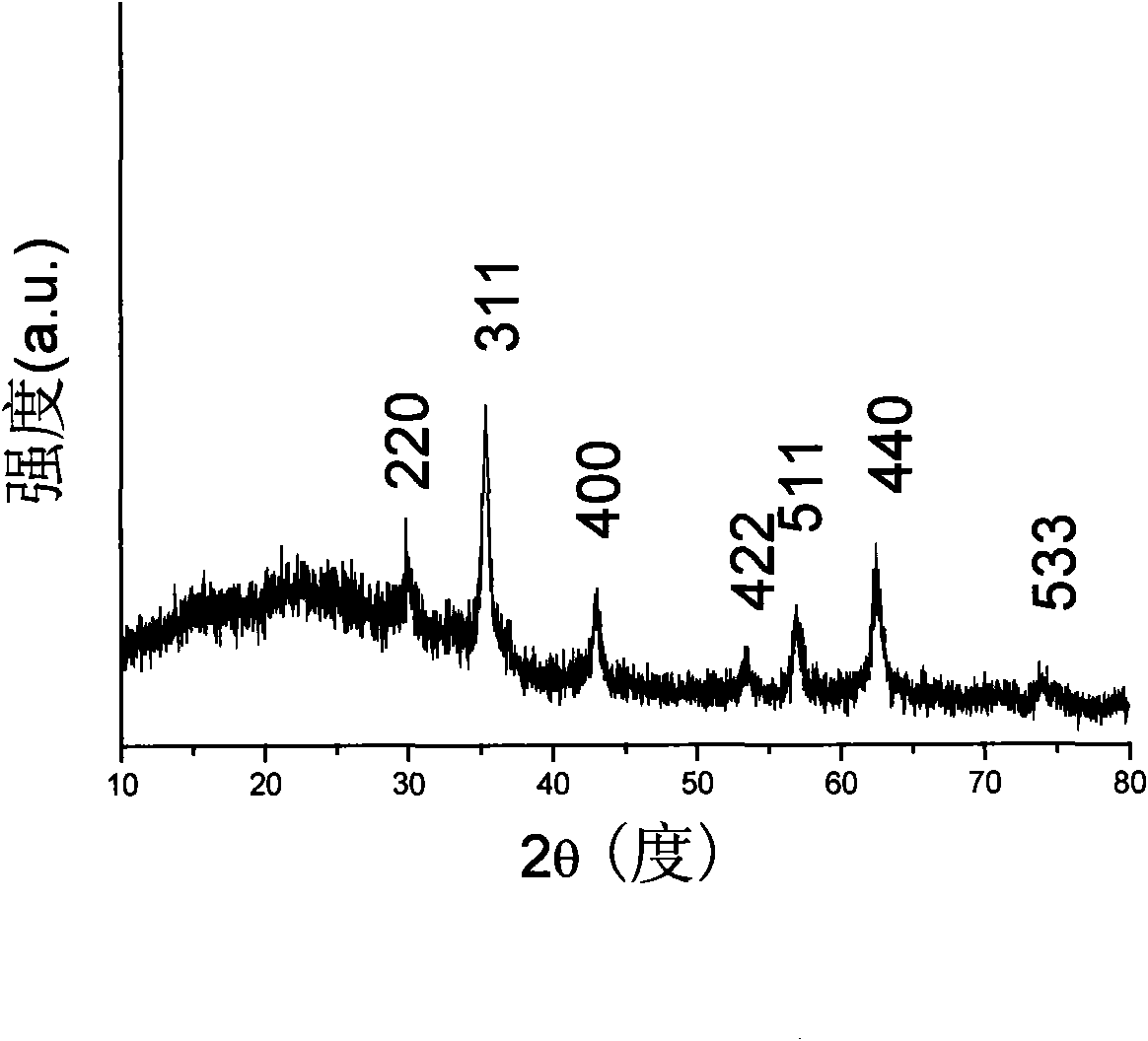

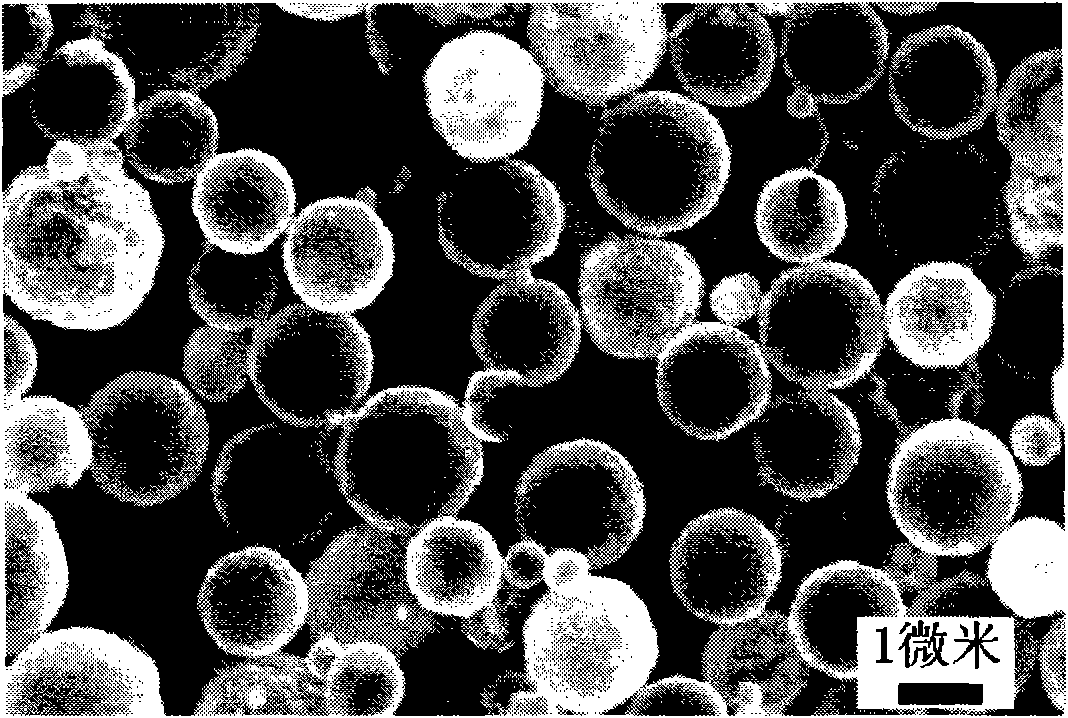

Embodiment 1

[0035] (1) Disperse succinic acid in a certain amount of deionized water, magnetically stir evenly, and its initial concentration is 0.2g / mL;

[0036] (2) Dispersing ferric nitrate in the solution obtained in step (1), stirring evenly with a magnetic field, with an initial concentration of 0.2 g / mL, to obtain an aqueous solution of the precursor;

[0037] (3) Transfer the aqueous solution of the precursor obtained in step (2) to a microwave humidifier. Under the action of ultrasonic waves, the aqueous solution of the precursor obtained in step (2) is atomized into small droplets, and transported to the tube-type humidifier by nitrogen gas. in a quartz tube in a furnace. The nitrogen flow rate is 15 standard liters per minute (SLPM), and the temperature of the tube furnace is set at 1000°C;

[0038] (4) Collect the target product (collection time is about 1 hour) from step (3) quartz tube with the water tank that is housed, collect the product that obtains in the water tank wi...

Embodiment 2

[0041] (1) Disperse malic acid in a certain amount of deionized water, stir it evenly with a magnetic field, and its initial concentration is 0.2g / mL;

[0042] (2) Disperse cobalt chloride in the solution obtained in step (1), stir magnetically evenly, and its initial concentration is 0.2g / mL to obtain an aqueous precursor solution;

[0043] (3) Transfer the aqueous solution of the precursor obtained in step (2) to a microwave humidifier. Under the action of ultrasonic waves, the aqueous solution of the precursor obtained in step (2) is atomized into small droplets, and transported to the tube-type humidifier by nitrogen gas. in a quartz tube in a furnace. The nitrogen flow rate is 15 standard liters per minute (SLPM), and the temperature of the tube furnace is set at 1000°C;

[0044] (4) Collect the target product (collection time is about 1 hour) from step (3) quartz tube with the water tank that is housed, collect the product that obtains in the water tank with the magnet,...

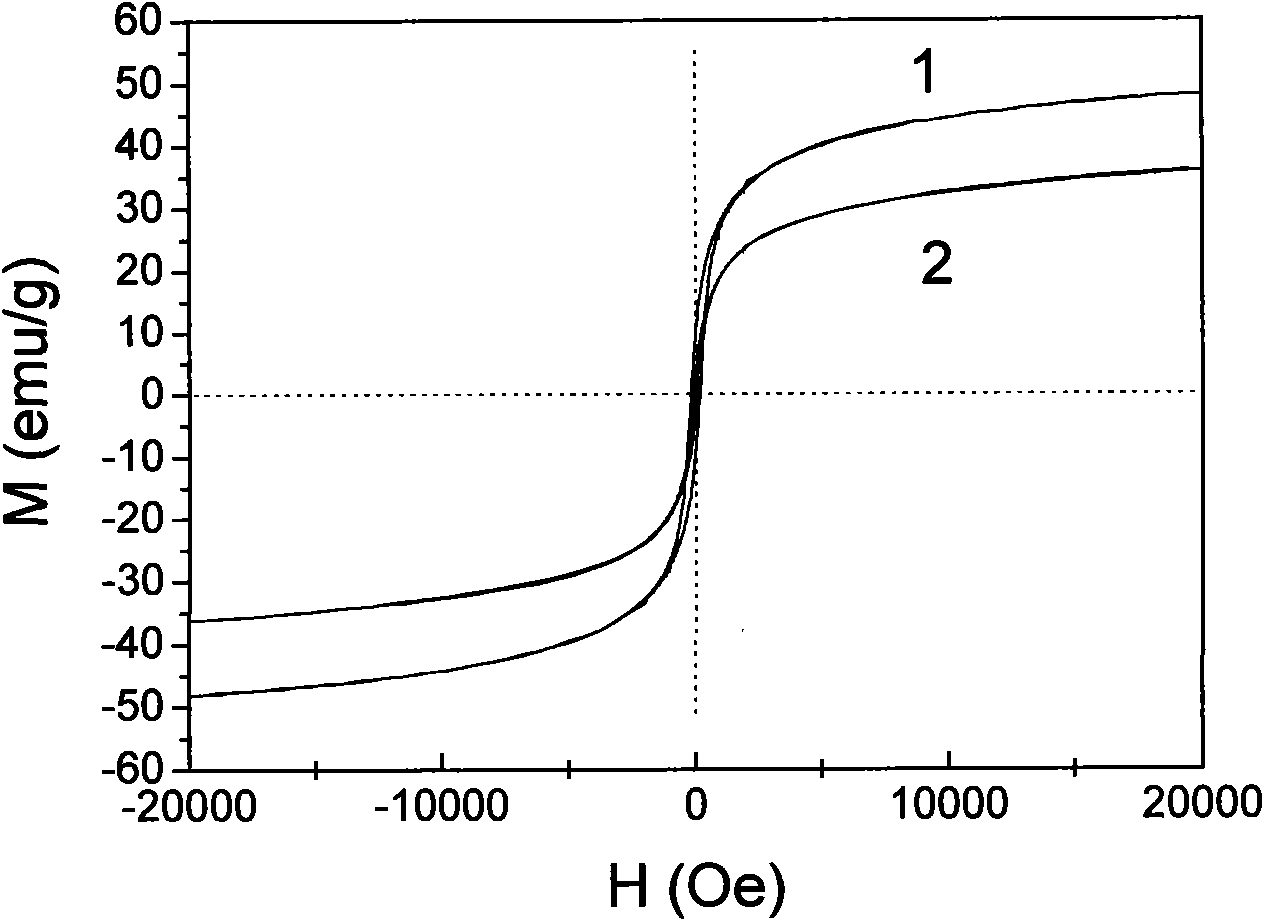

Embodiment 3

[0046] (1) Disperse citric acid in a certain amount of deionized water, stir evenly with a magnetic field, and its initial concentration is 0.2g / mL;

[0047] (2) Disperse ferrous chloride and cobalt chloride in the solution obtained in step (1), stir evenly with a magnetic field, and the initial concentrations are 0.12g / mL and 0.08g / mL respectively, to obtain an aqueous precursor solution;

[0048] (3) Transfer the aqueous solution of the precursor obtained in step (2) to a microwave humidifier. Under the action of ultrasonic waves, the aqueous solution of the precursor obtained in step (2) is atomized into small droplets, and transported to the tube-type humidifier by nitrogen gas. in a quartz tube in a furnace. The nitrogen flow rate is 15 standard liters per minute (SLPM), and the temperature of the tube furnace is set at 1000°C;

[0049] (4) Collect the target product (collection time is about 1 hour) from step (3) quartz tube with the water tank that is housed, collect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com