Method for synthesizing N,N-diethyl ethanolamine

A diethylethanolamine and synthesis method technology, applied in the N field, can solve the problems of high reaction temperature, expensive catalyst, etc., and achieve the effects of avoiding side reactions, increasing equipment utilization, and reducing the probability of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

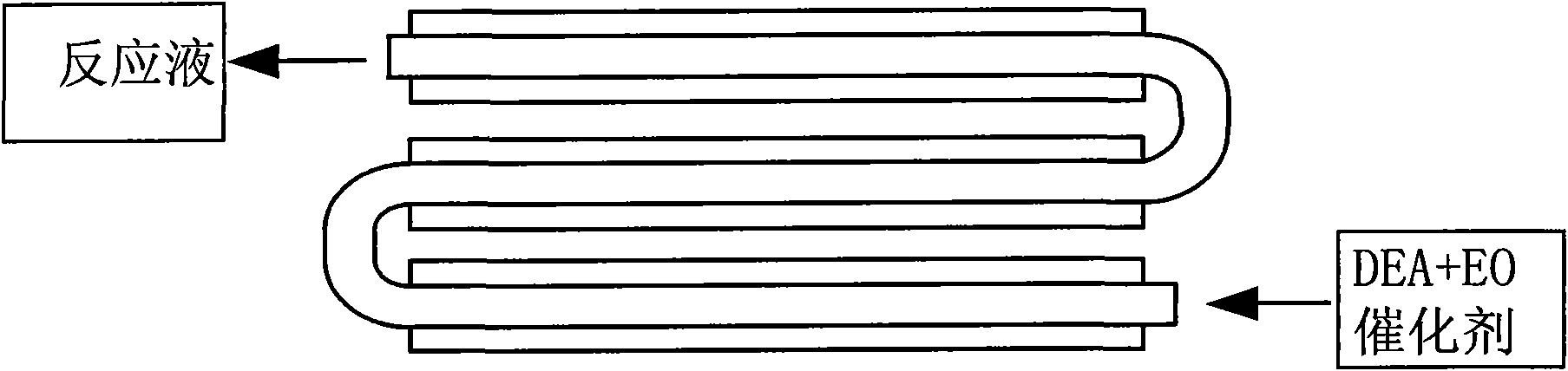

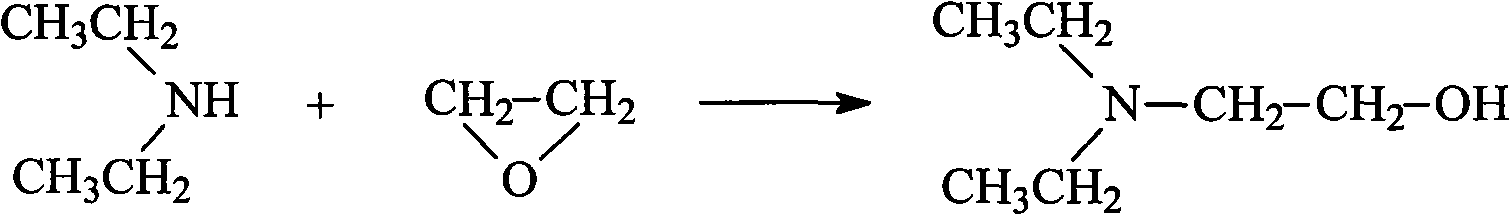

Method used

Image

Examples

Embodiment 1

[0022] In a Φ30mm metal tubular reactor with a total length of 2m, 731.4g / h (10mol / h) of diethylamine, 88.1g / h (2.0mol / h) of ethylene oxide, and Catalyst zinc chloride 7g / h was added continuously, cooling water at 25°C was introduced into the jacket of the reactor, and the flow rate of cooling water was adjusted to keep the reaction temperature basically constant at 50±5°C. The composition of the final analysis reaction liquid is: DEA70.9%, catalyst 0.8%, DEEA28.1%, high boiler 0.2%.

Embodiment 2

[0024] In a Φ30mm metal tubular reactor with a total length of 2m, 731.4g / h (10mol / h) of diethylamine, 176.2g / h (4.0mol / h) of ethylene oxide, and Catalyst zinc chloride 7g / h was added continuously, cooling water at 25°C was introduced into the jacket of the reactor, and the flow rate of cooling water was adjusted to keep the reaction temperature basically constant at 50±5°C. The composition of the final analysis reaction liquid is: DEA48.6%, catalyst 0.7%, DEEA49.2%, high boiling substances 1.5%.

Embodiment 3

[0026] In a Φ30mm metal tubular reactor with a total length of 2m, 731.4g / h (10mol / h) of diethylamine, 88.1g / h (2.0mol / h) of ethylene oxide, and Catalyst ferric chloride 7g / h was added continuously, cooling water at 25°C was passed into the jacket of the reactor, and the flow rate of cooling water was adjusted to keep the reaction temperature basically constant at 50±5°C. The composition of the final analysis reaction liquid is: DEA71.1%, ethylene oxide 0.1%, catalyst 0.8%, DEEA27.8%, high boiler 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com