Modular removable thermal insulation

A modular, removable technology for the protection of pipes through thermal insulation, heat exchange equipment, climate sustainability, etc., which can solve problems such as difficult access to frame members, complex installation, and inability to ensure surface isothermal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] best practice

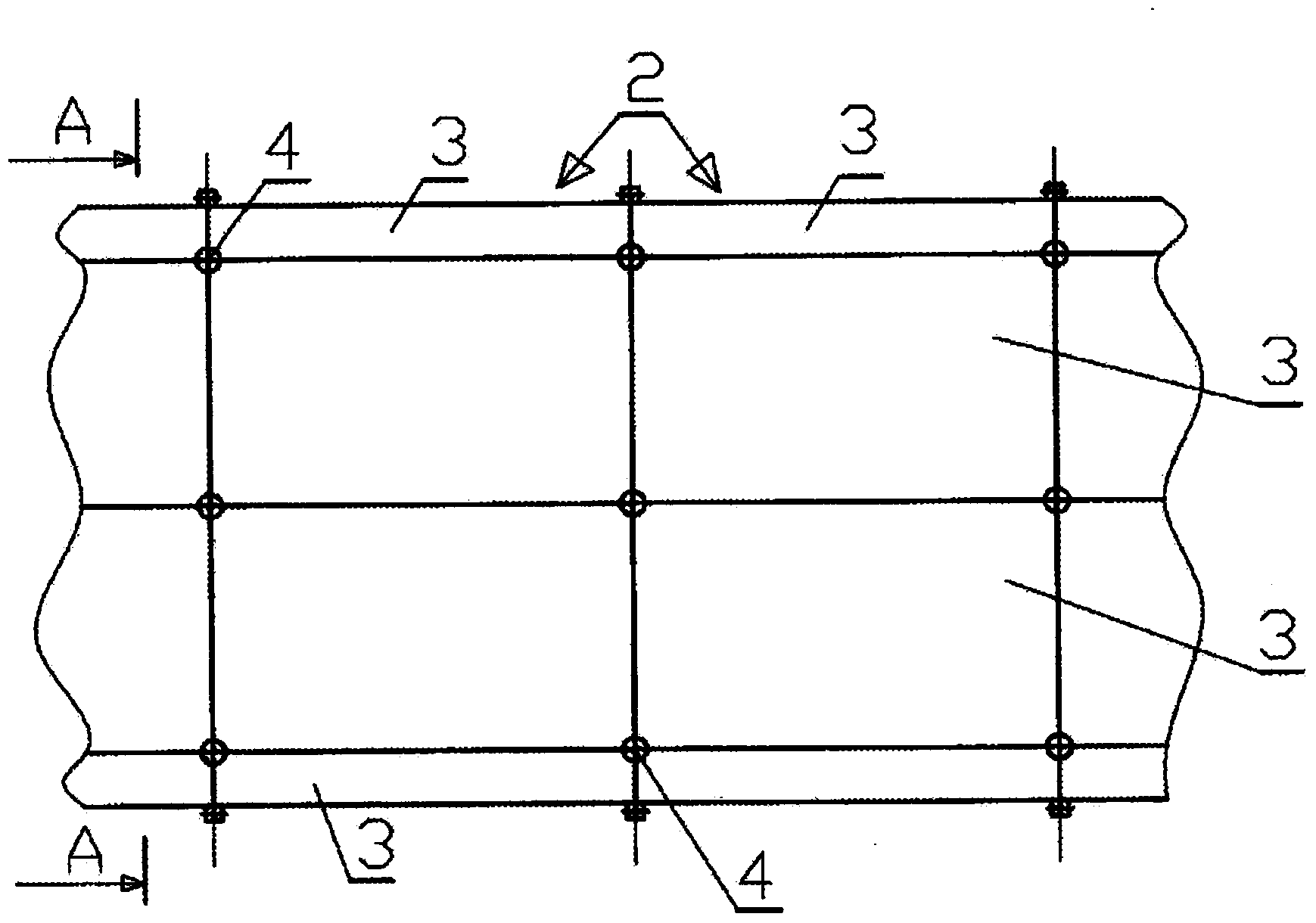

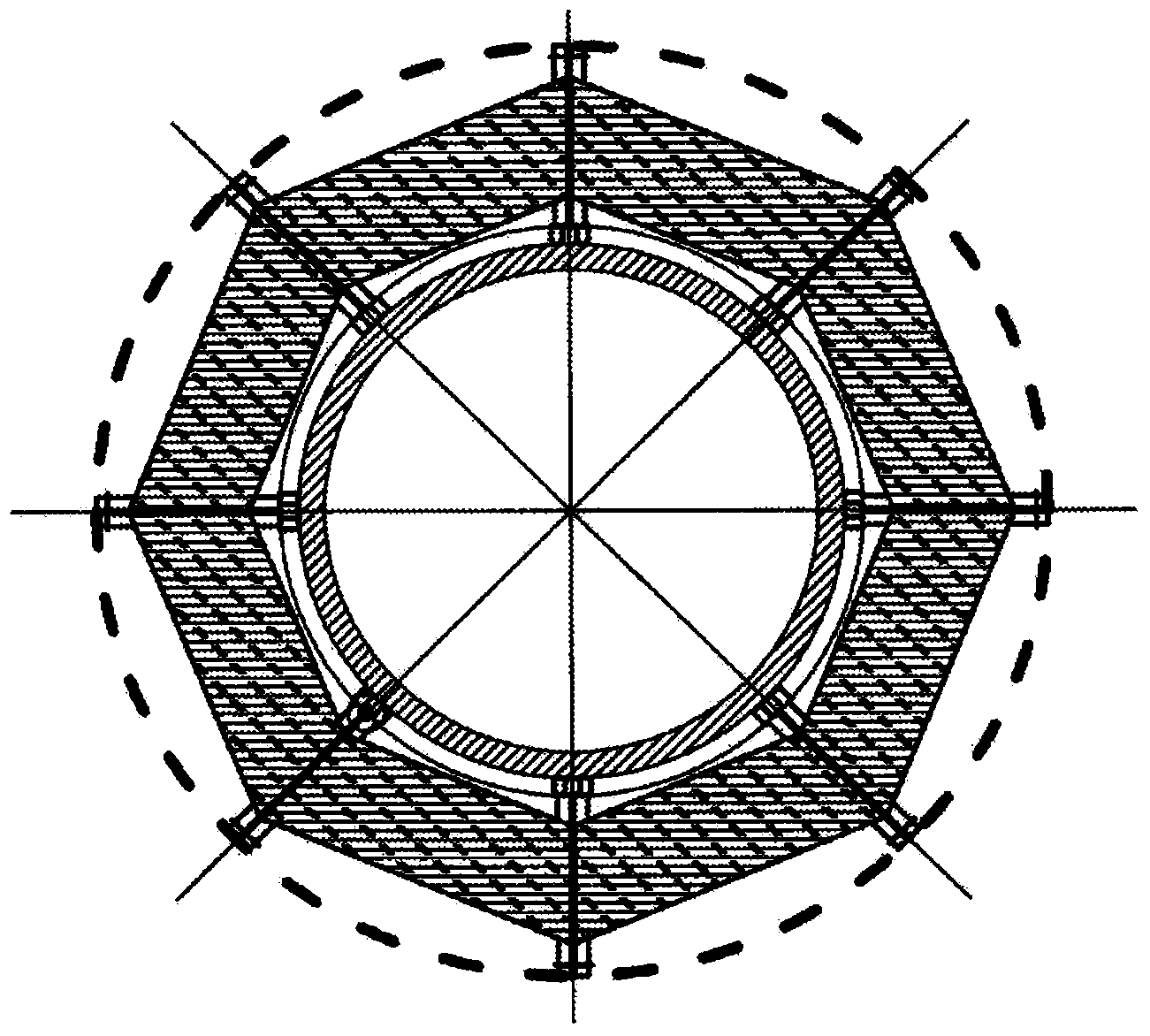

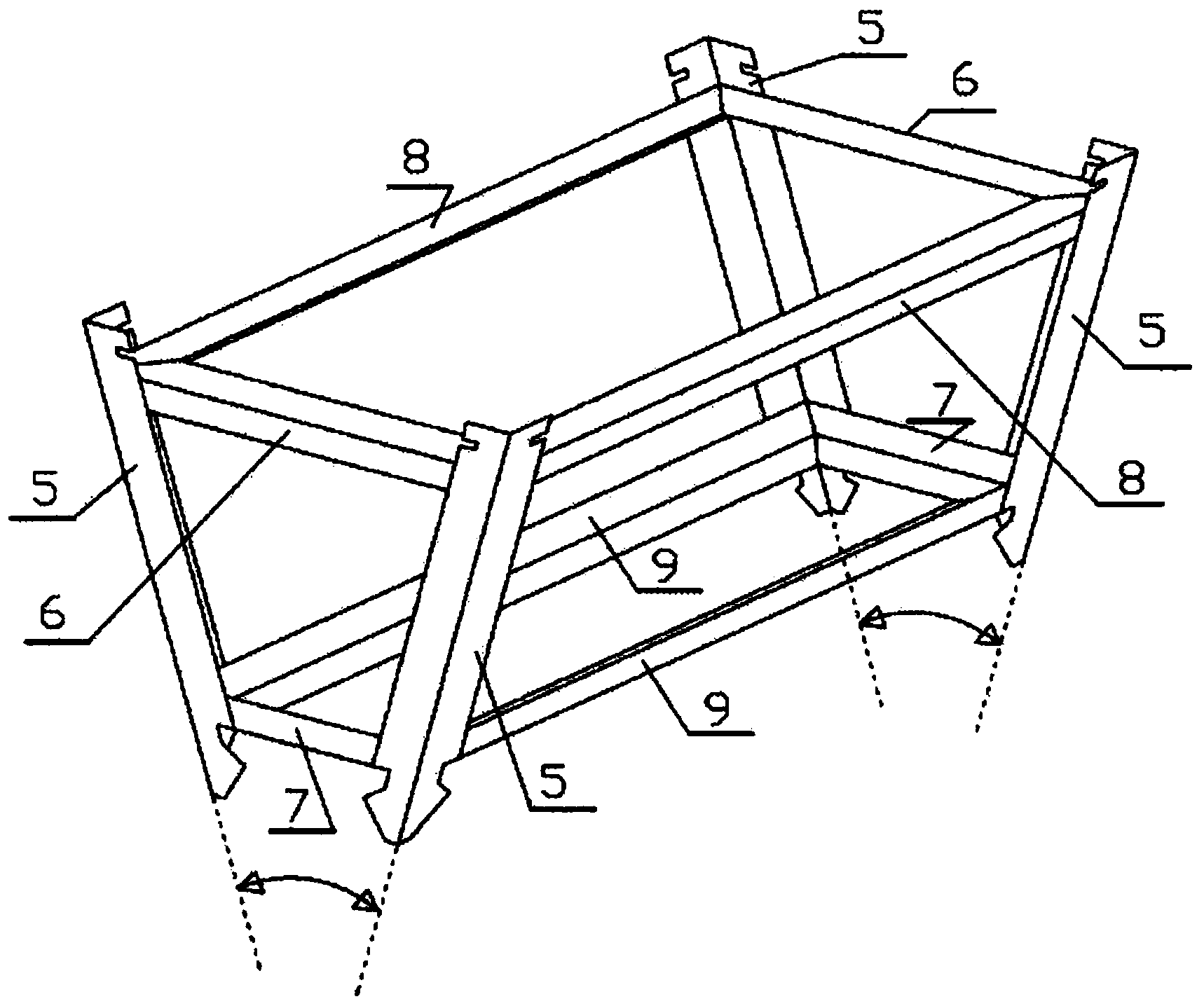

[0051] The modular removable thermal insulation structure according to the invention comprises circular segments 2 distributed longitudinally in series on the outer surface of the equipment to be insulated, for example the outer surface of the pipe 1; and the circular segments 2 close to each other. Each circular segment consists of N identical thermal insulation modules (TIM) 3 . The thermal insulation modules 3 abut against each other; and the side walls of the TIM 3 of adjacent sections are arranged opposite to each other. Thus, each of the four corner posts between the side walls of each TIM 3 butts along a joint line 4; wherein this joint line 4 extends in a direction normal to the surface of the device to be insulated. On the one hand, between the side walls of the TIM 3 there is a corner fitting corresponding to each corner post, the corner fittings being located in the same segment and in the vicinity of the TIM 3 . On the other hand, there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com